Controller of capacitor energy storing apparatus and its control

A control device and capacitive energy storage technology, applied in energy storage discharge welding, welding power supply, etc., can solve problems such as failure to meet welding requirements, failure to use working methods, inconsistent welding effects, etc., to achieve intuitive operation interface image, improve productivity, The effect of welding current stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

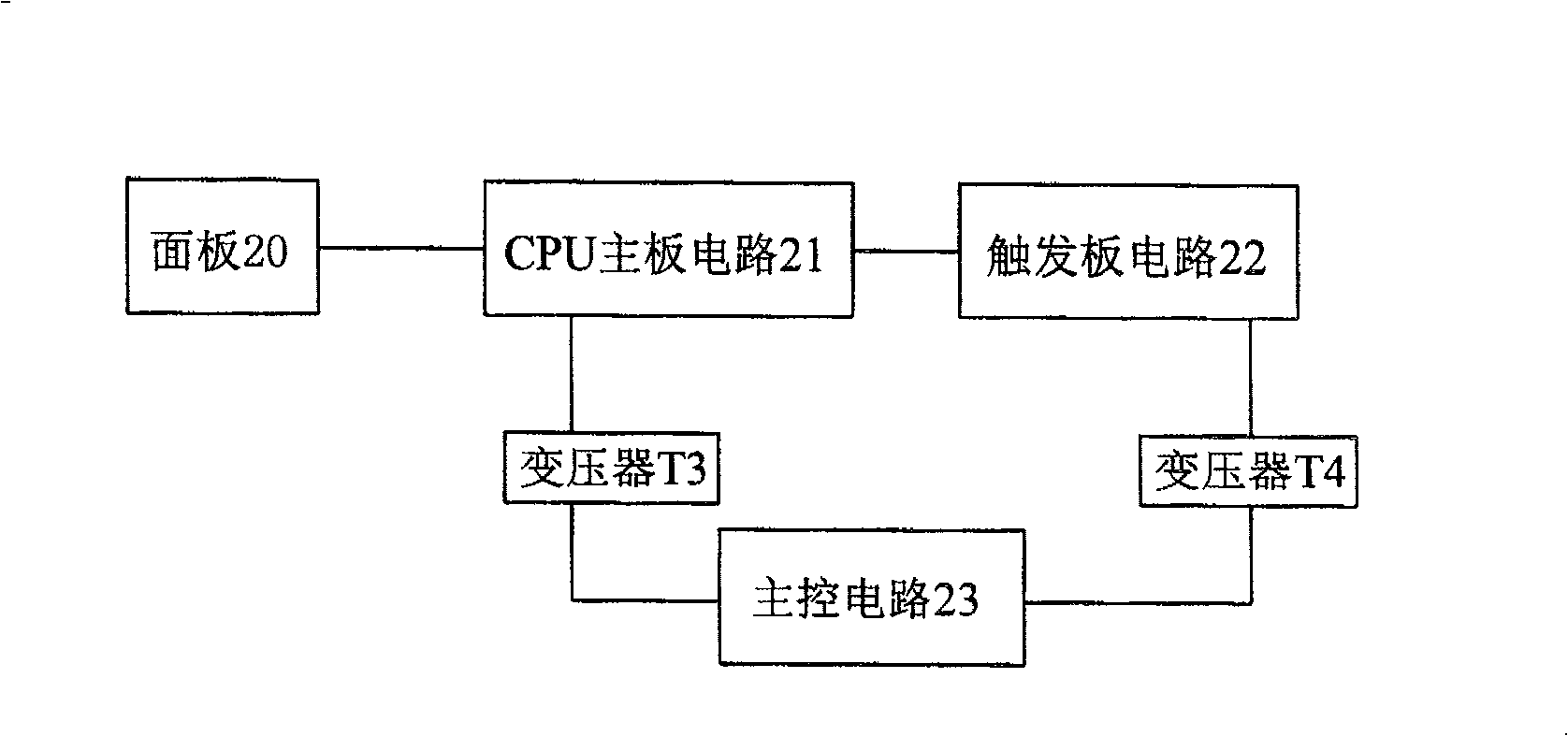

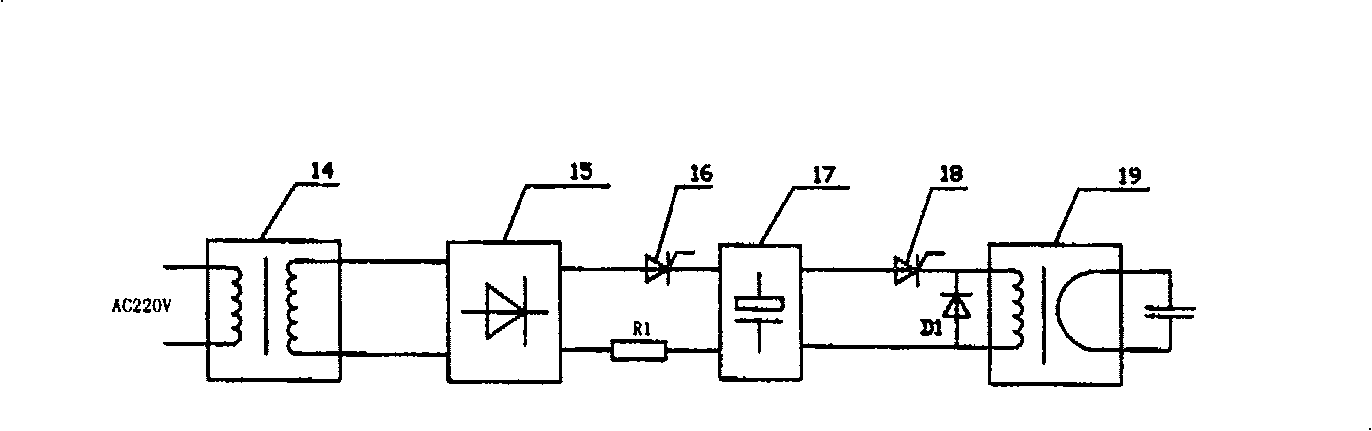

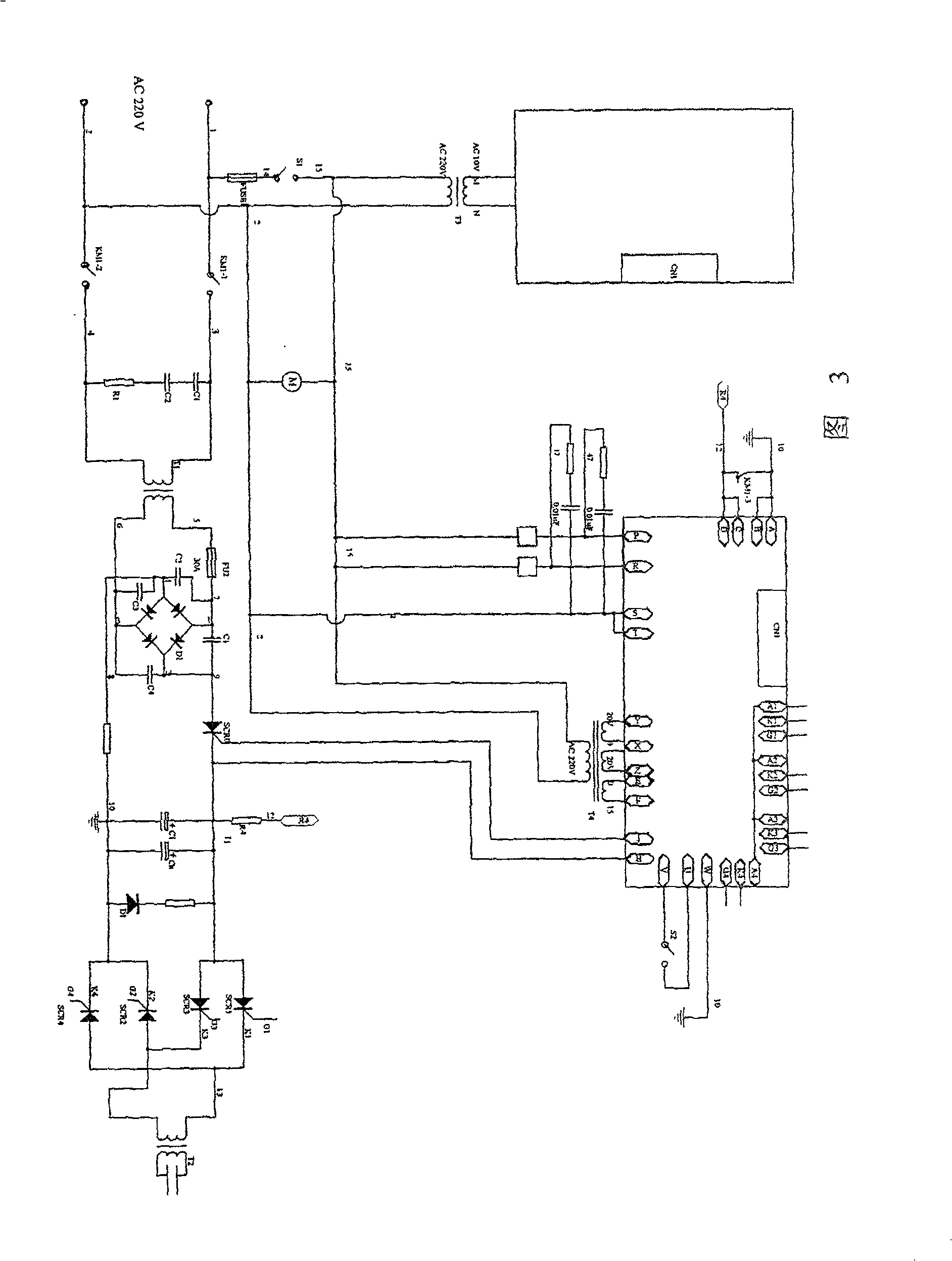

[0041] Capacitor energy storage spot welding uses capacitors to store energy. When the energy can melt a small area of solder joints, the capacitors are discharged instantaneously. Compared with other welding methods, such as AC, the instantaneous power taken from the grid is low, the load of each phase is balanced, and the power factor is high, and it can provide concentrated energy to the welding area, and can obtain weldments with good surface quality and small deformation. Weld some non-ferrous metals with good thermal conductivity and difficult to weld, suitable for welding aluminum, copper silver, nickel metal and alloy materials. This welding method has been widely used in industrial production, such as hardware, household appliances, electronics, metal utensils and other industries. The welding machine is composed of mechanical parts and electrical parts, and circuit control is the core part of resistance welding technology. Single-chip computer control technology i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com