Dynamic-contact braided-line cold press of circuit breaker

A technology of moving contacts and circuit breakers, which is applied in the directions of circuit breaker contacts, circuit breaker components, circuits, etc., can solve the problems of unresolved energy consumption, long energization time, and hardened braided wires. The effect of large-scale industrial production, reliable product quality and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

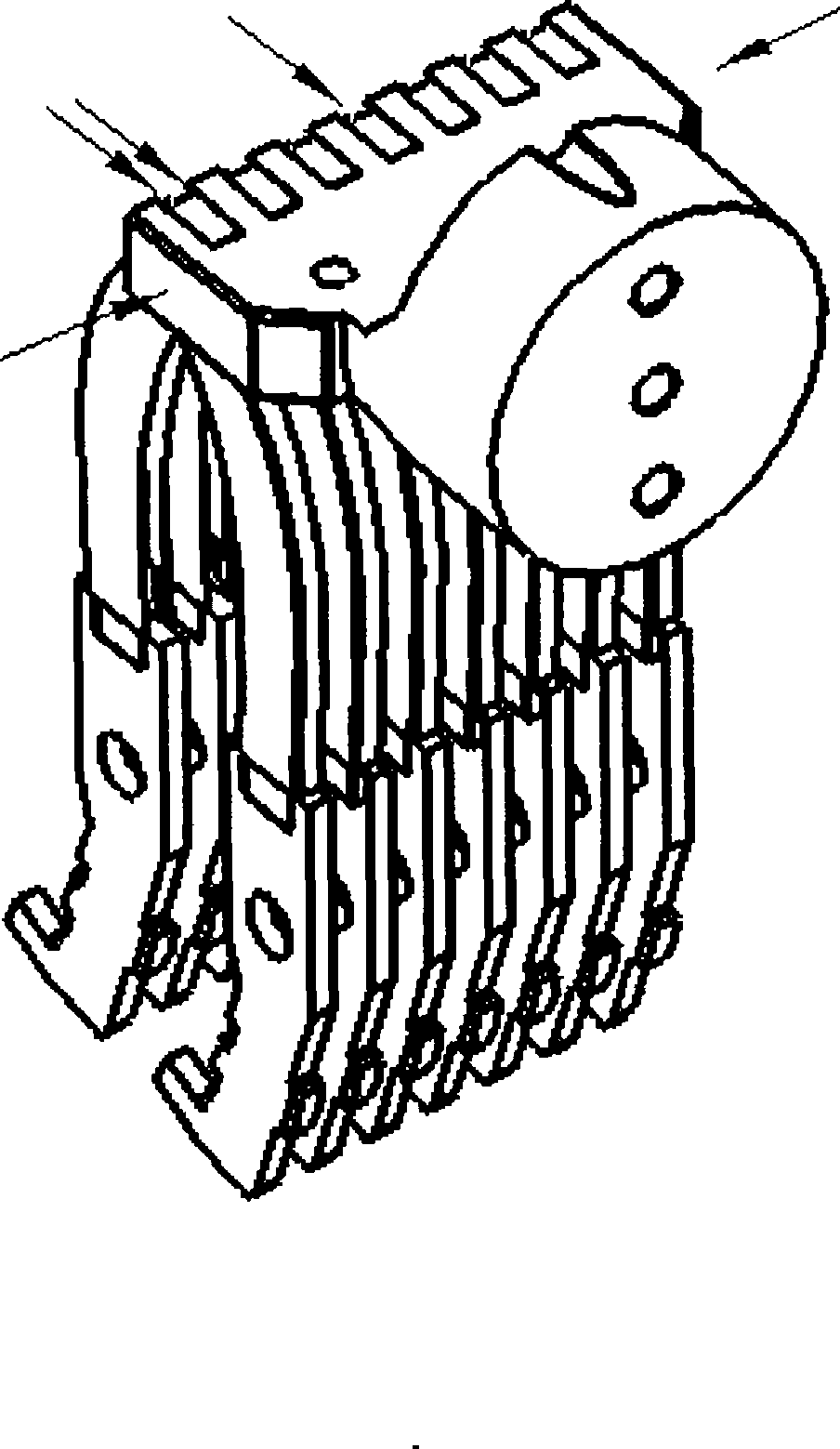

[0016] The implementation of the cold extrusion process of the circuit breaker moving contact braided wire according to the present invention will be described in detail below in conjunction with the accompanying drawings:

[0017] The cold extrusion process of the moving contact braided wire of the circuit breaker is divided into two parts: pretreatment and cold extrusion of the parts of the moving contact braided wire of the circuit breaker; among them, the process of the pretreatment part is:

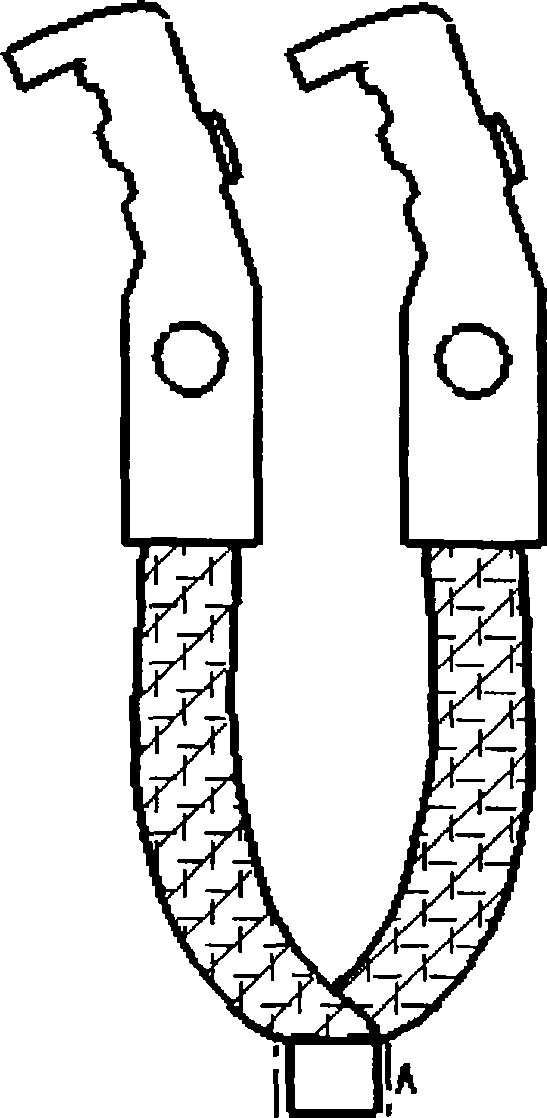

[0018] Use a cloth grinder to remove copper oxide on the four sides of the contact A end in Figure (1), and make the four sides of the static fit part of the contact A end flat, without bumps, and the size meets the static fit requirements;

[0019] Cold extrusion process:

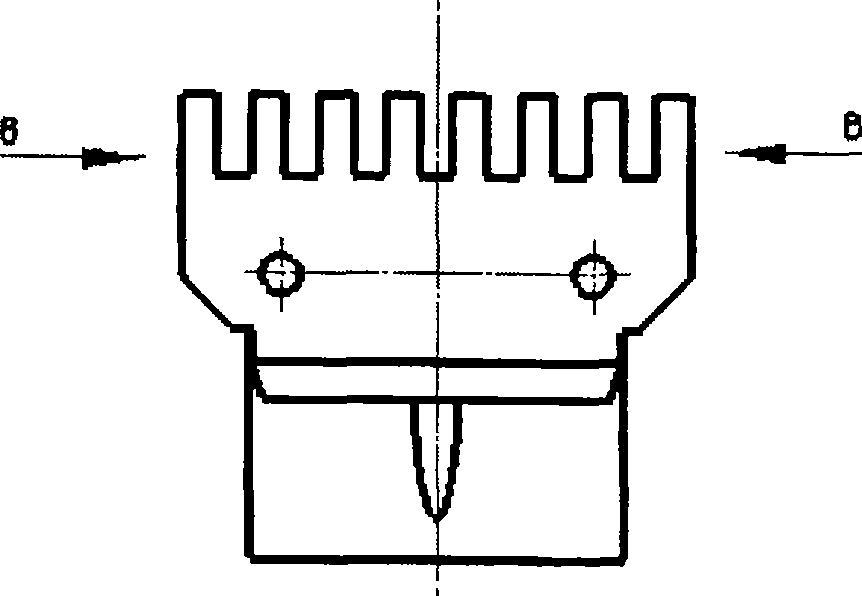

[0020] a. Use the designed special fixture 2 for the contact braided line, whose width is 2 mm wider than both sides of the busbar groove in Figure (2); use a press with a pressure of 25 to 40 tons to press the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com