Method for manufacturing wave shaped spring

A technology of wave springs and manufacturing methods, which is applied in the manufacture of wave springs and the field of spring manufacturing, can solve problems such as peaks and troughs not corresponding, not tight enough and loose, low product qualification rate, etc., to achieve compact product structure and perfect appearance structure , the effect of high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] A manufacturing method of a wave spring, characterized in that the CNC spring coiling machine equipment is refitted into winding multi-layer wave spring equipment for production, and the method is as follows:

[0032] The first step: equipment modification

[0033] Retrofit the CNC coil spring machine equipment to coil multi-layer wave spring equipment;

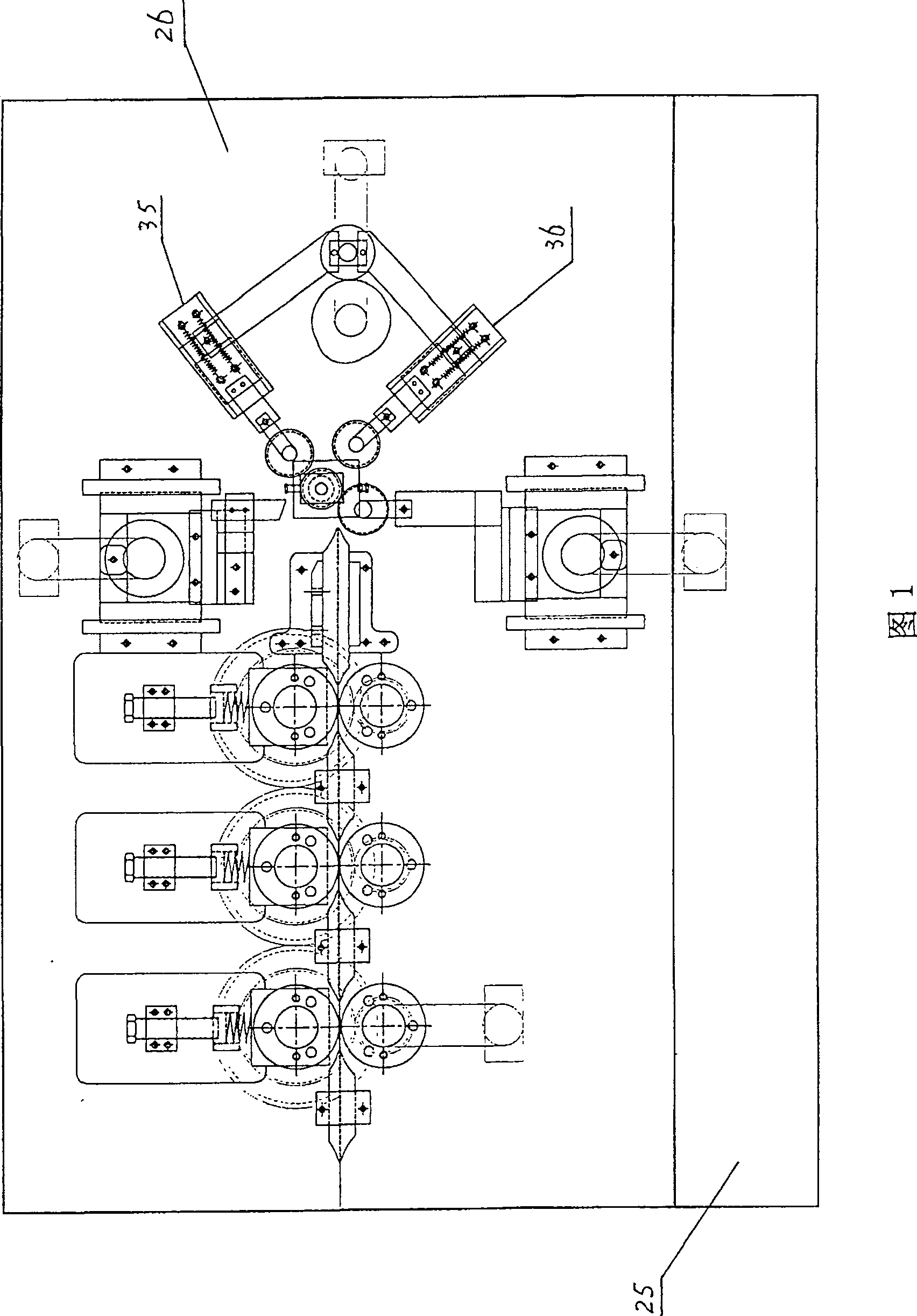

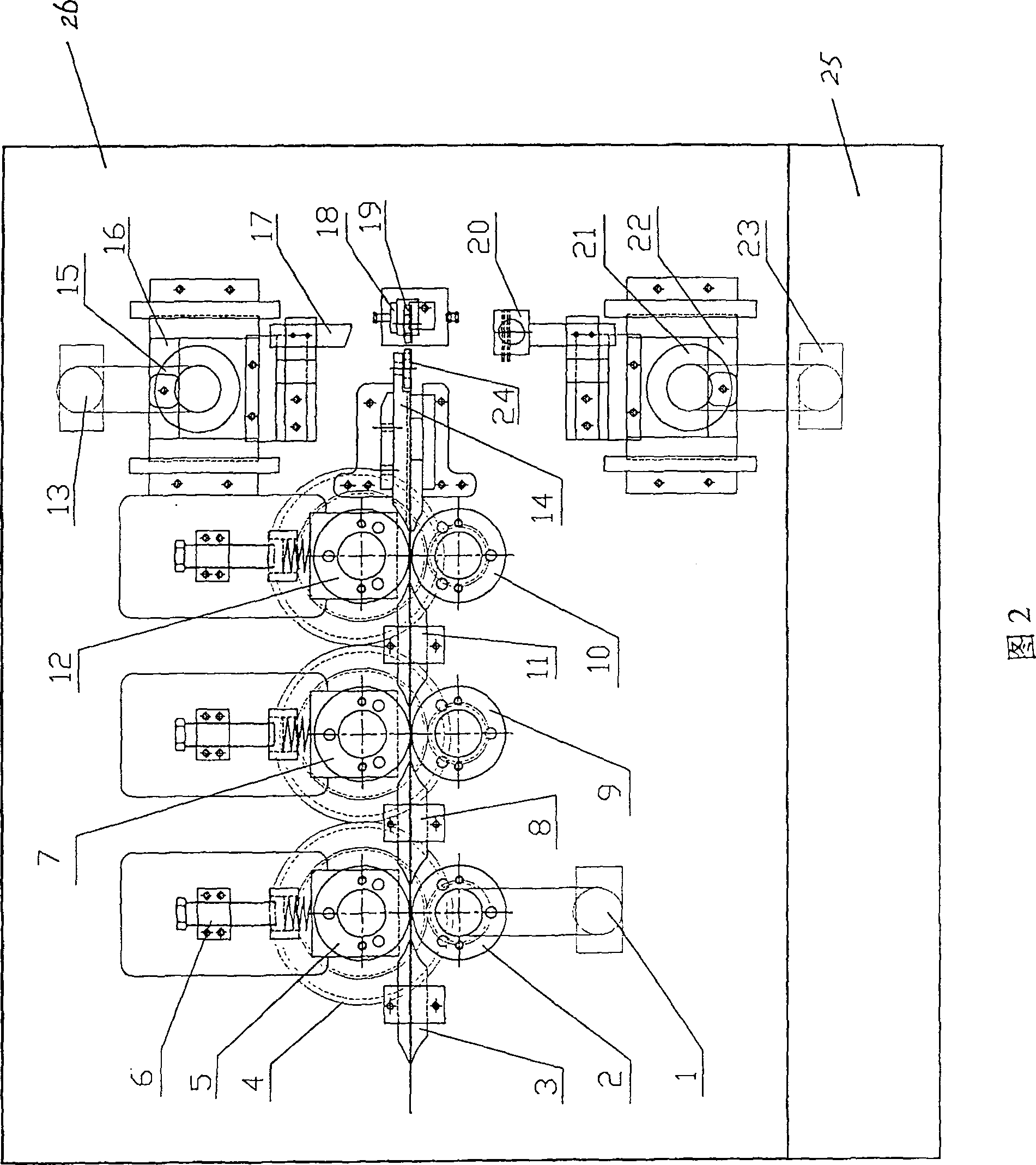

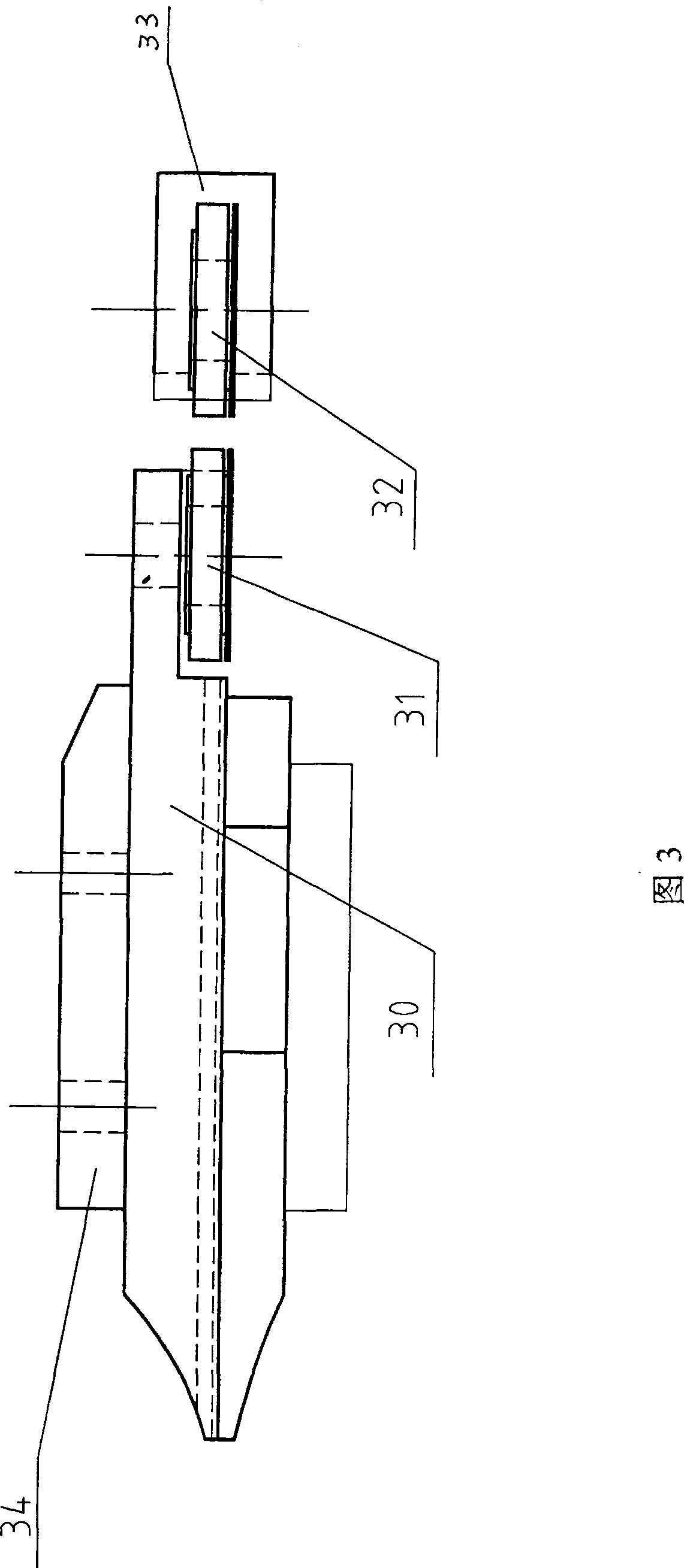

[0034] As shown in Figure 1, it is a schematic diagram of the equipment structure of the CNC spring coiling machine. The CNC spring coiling machine was originally a five-axis linkage CNC machine with five servo motors driving the X-axis, Y-axis, Z-axis, A-axis, and B-axis. The device consists of the first servo motor 1, the second servo motor 13, the third servo motor 23, the first roller 2, the second roller 5, the third roller 7, the fourth roller 9, the fifth roller 10, and the sixth roller 12 , the first guide plate 3, the second guide plate 8, the third guide plate 11, the gear 4, the adjustment screw 6, the outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com