Stainless steel plate integral burner for gas range

A stainless steel plate and burner technology, which is applied to heating fuels, household stoves/stoves, gaseous heating fuels, etc. Mass production, simple processing and manufacturing process, and the effect of facilitating transportation and warehousing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

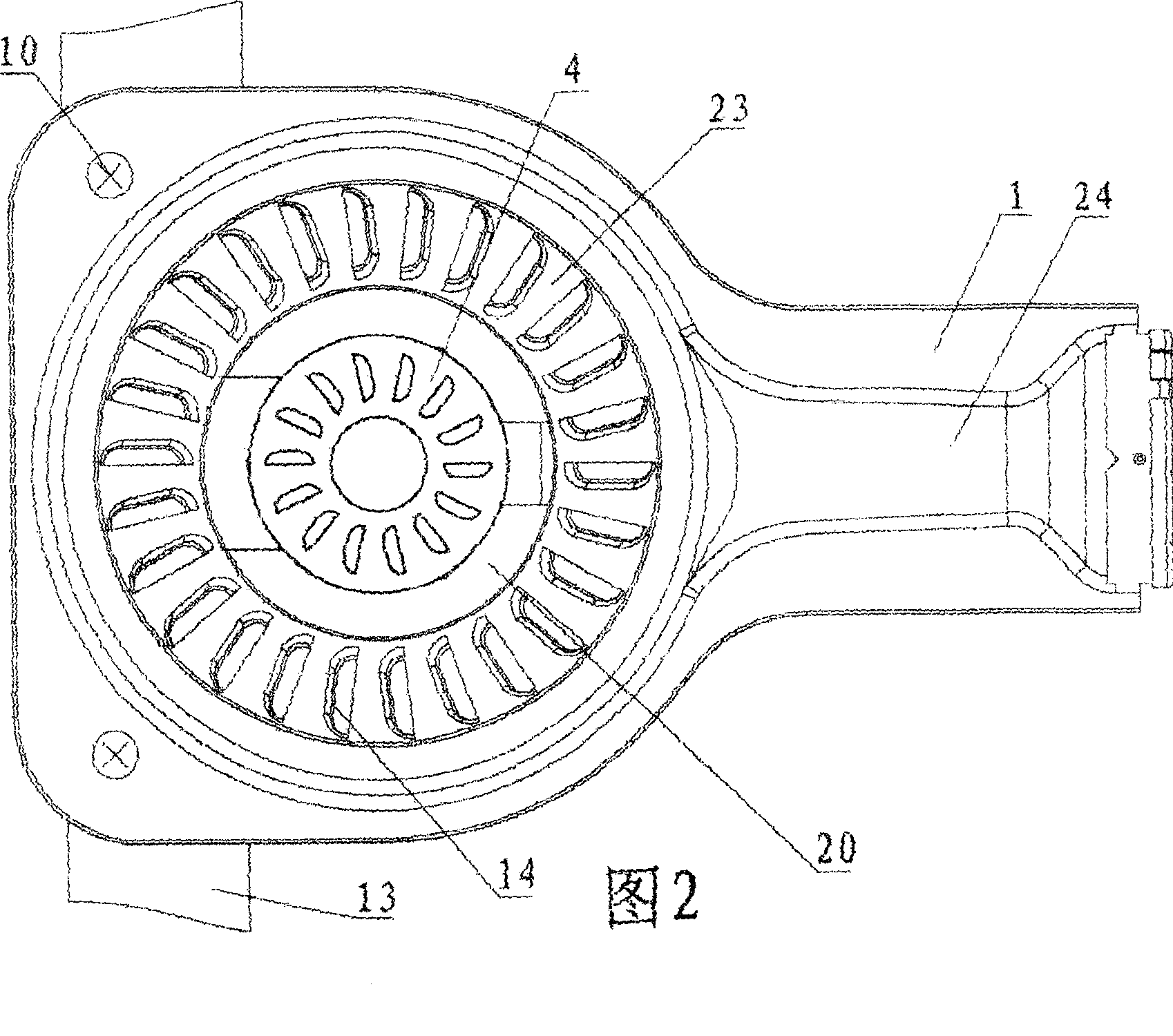

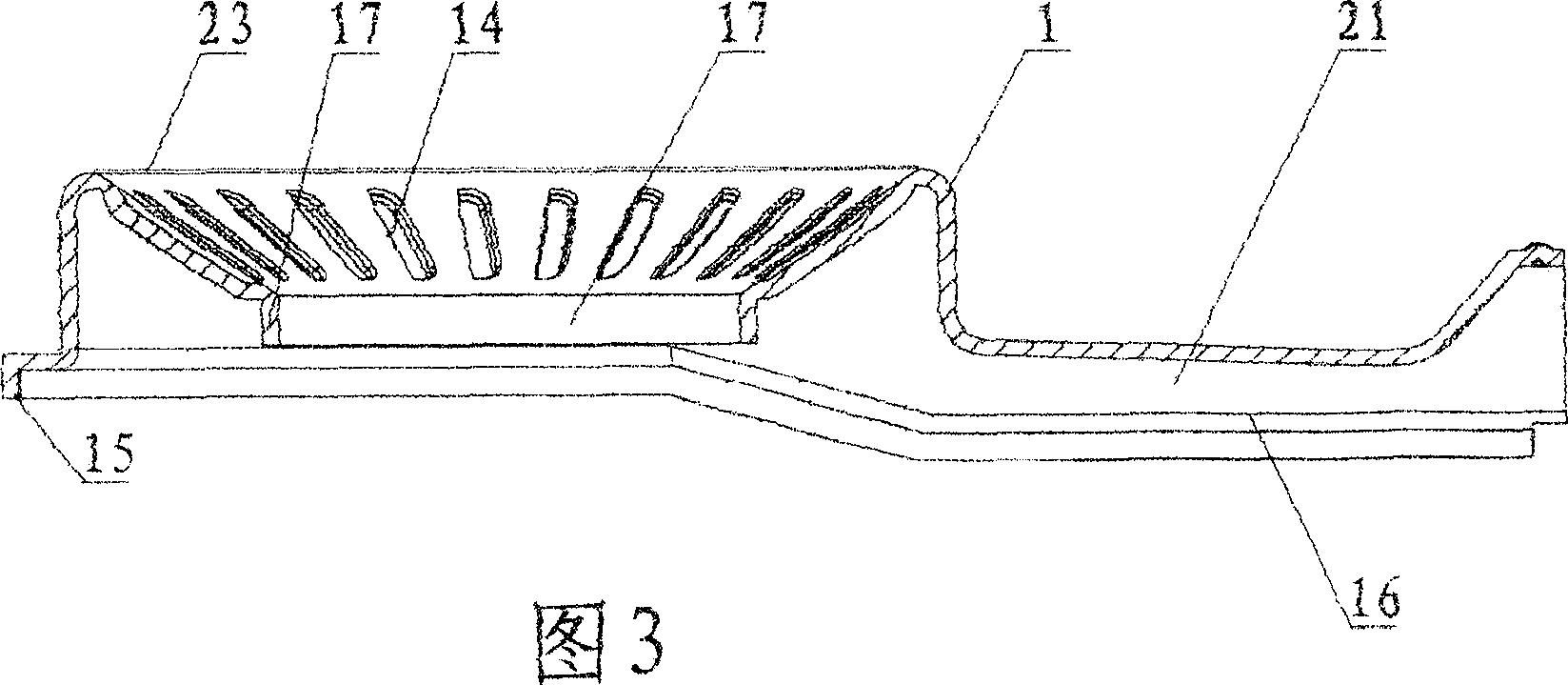

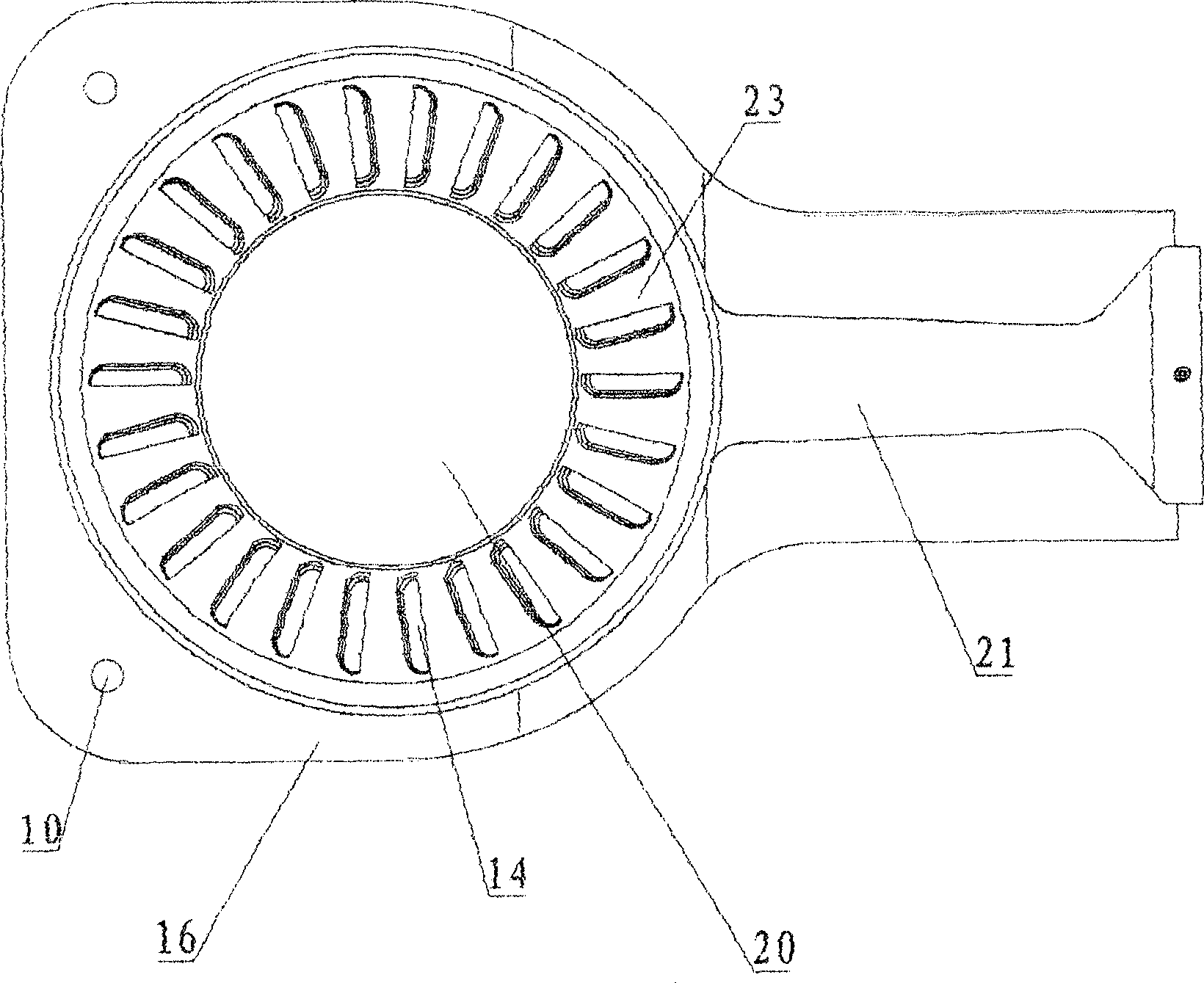

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0016] The burner that is commonly used at present has its burner head and the ejector tube of the mixed gas manufactured separately, and some stoves have several burner parts, which are inconvenient to manufacture and assemble. The burner adopts the upper body pressure plate 16 and The two stainless steel plates of the lower body pressing plate 19 are integrally punched and formed into the burner upper body 1 and the burner lower body 2 as a whole, and the burner upper body 1 (that is, the original upper body pressing plate 16) is punched and formed. ) and the lower body 2 of the burner (that is, the original lower body pressing plate 19), riveted the edge plate 15, and at the same time, the upper body hole side socket ring 17 is inserted into the lower body hole and the side socket ring 18 is fastened and fastened to form an integral burner .

[0017] The upper bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com