Steamed bread leavening technical process and apparatus

A proofing and equipment technology, which is applied in the directions of dough fermenter, pre-baking dough processing, baking, etc., can solve problems such as inability to measure normally, accurately control humidity, uncontrollable temperature of proofing equipment, inaccurate control of temperature and humidity, etc. , to solve the inertia and temperature accumulation, the control is simple and convenient, and the control accuracy is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

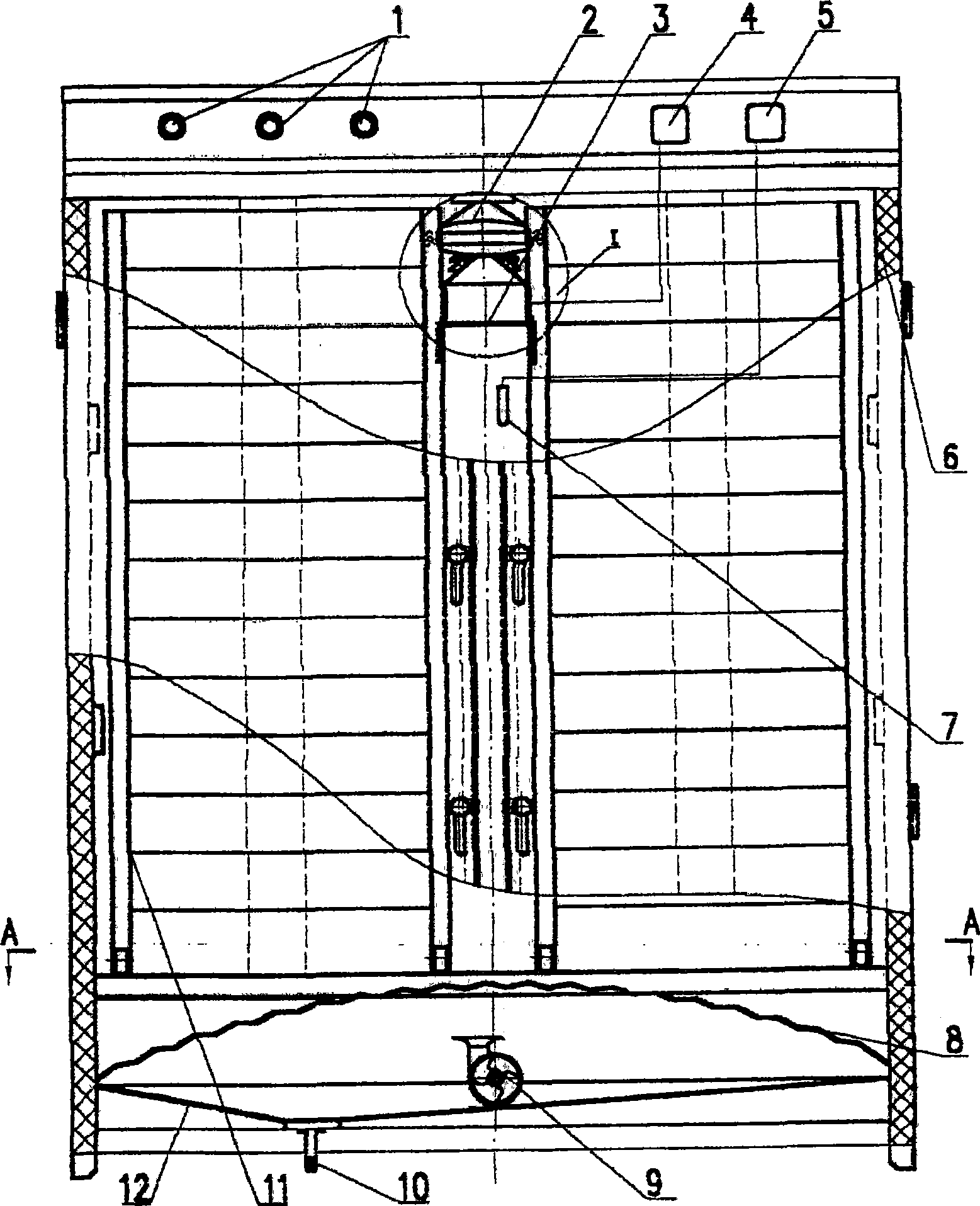

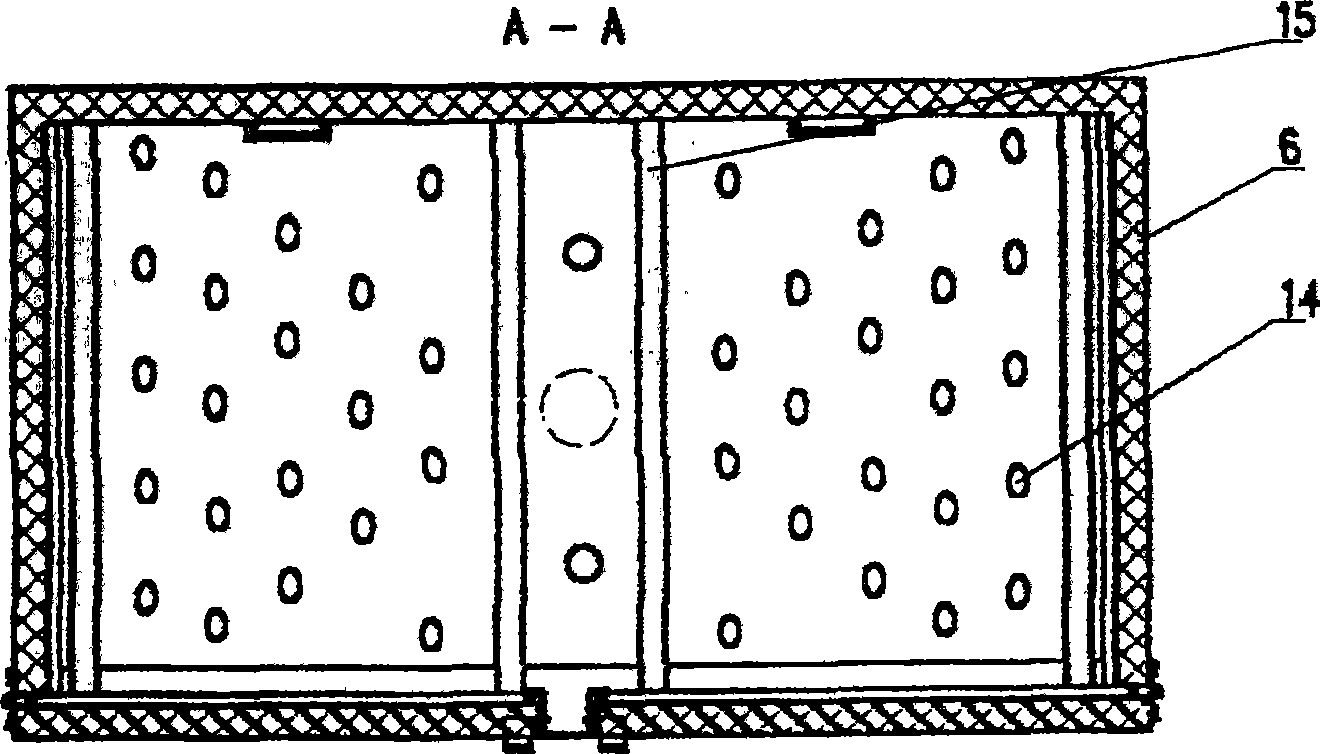

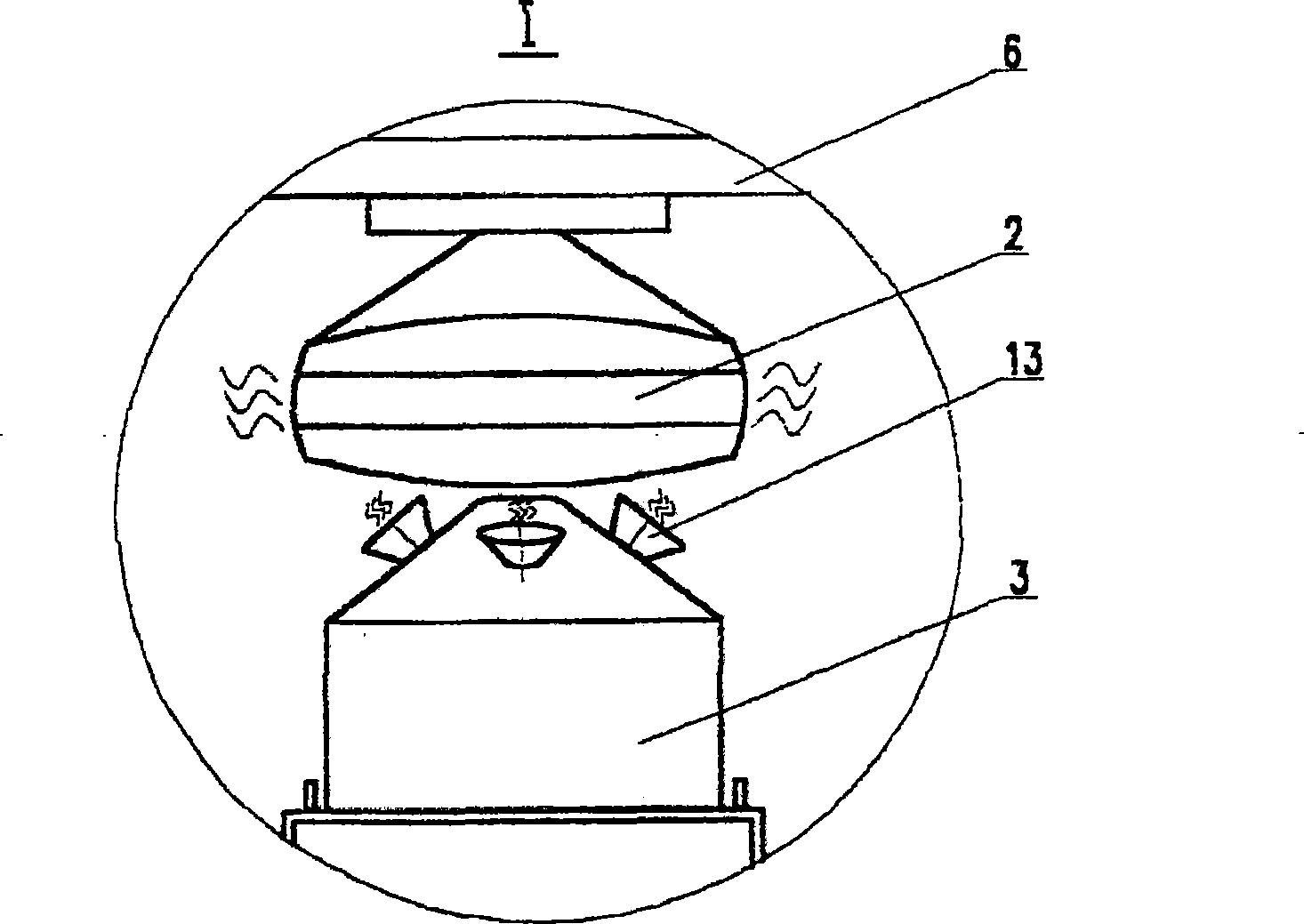

[0016] The proofing process of the steamed bun of the present invention is to place the formed steamed bread blank in a proofing device whose temperature is maintained in the range of 35-38℃, and a hot air blower provides proofing heating, and the proofing temperature is adjusted and controlled by turning on or off the hot air blower. During the proofing process, the proofing environment of the steamed buns is that the proofing humidity is always maintained at 100%. The specific method is to use a cold moisture generator to generate cold moisture, and the generation rate of cold moisture is greater than that of cold moisture. Condensation speed, the proofing environment is kept full of cold moisture, and the humidity is kept at 100%. In such a high humidity environment, the steamed bread blanks can fully absorb water on the surface of the proofing equipment, which can make the steamed bread fully formed in the steamer. The gelatinization is thorough, so that the steamed buns have ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com