Solidifying and drying method for raw plate production of lead acid batteries

A lead-acid battery, curing and drying technology, applied in the direction of lead-acid battery electrodes, drying solid materials, heating to dry solid materials, etc., can solve the problems of unfavorable metal lead oxidation, excessive water loss, waste of pure water energy, etc., to achieve The effect of enhancing market competitiveness, reducing energy consumption, and saving pure water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

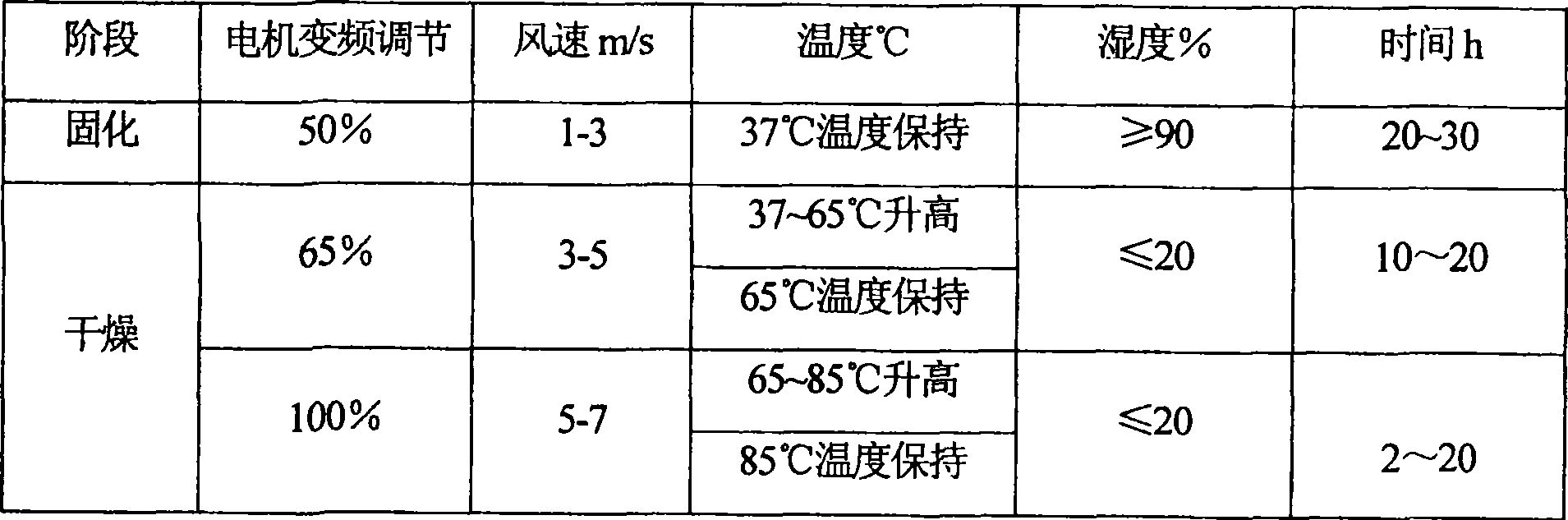

[0013] Example 1: The curing time is 20 hours, the frequency conversion of the motor in the pre-drying stage is adjusted to 65%, the wind speed is 3-5m / s, the temperature is set at 37°C and raised to 65°C in 10h, and the humidity is set at 20%. In the post-drying stage, the frequency conversion of the motor is adjusted to 100%, the wind speed is 5-7m / s, the temperature is set at 65°C and rises to 85°C in 4 hours, and the humidity is set at 10%. After sampling and testing, the free lead content, degree of dryness, and strength of the green board all meet the technical requirements.

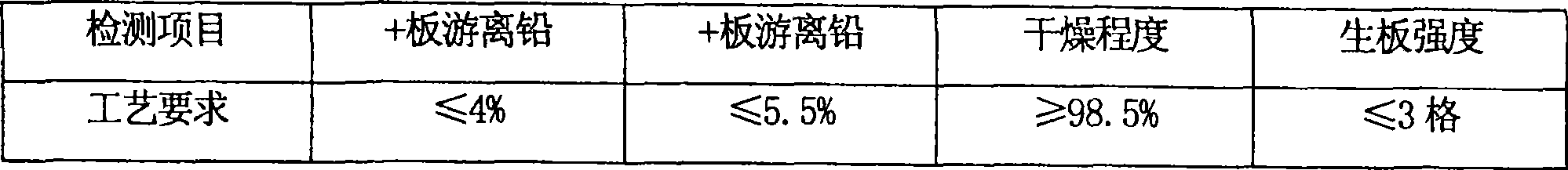

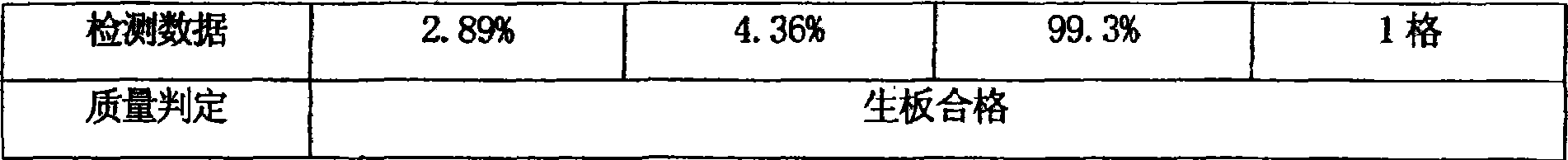

[0014] The specific test results are shown in the table below:

[0015]

[0016]

Embodiment 2

[0017] Example 2: The curing time is 30 hours, the frequency conversion of the motor in the pre-drying stage is adjusted to 65%, the wind speed is 3-5m / s, the temperature is set at 37°C and raised to 65°C in 5h, and the humidity is set at 20%. In the post-drying stage, the frequency conversion of the motor is adjusted to 100%, the wind speed is 5-7m / s, the temperature is set at 65°C and rises to 85°C in 10 hours, and the humidity is set at 10%. After sampling and testing, the free lead content, degree of dryness, strength of green board and average weight of a single piece of green board all meet the technical requirements.

[0018] The specific test results are shown in the table below:

[0019]

Embodiment 3

[0020] Example 3: The curing time is 30 hours, the frequency conversion of the motor in the pre-drying stage is adjusted to 65%, the wind speed is 3-5m / s, the temperature is set at 37°C and raised to 65°C in 8h, and the humidity is set at 20%. In the post-drying stage, the frequency conversion of the motor is adjusted to 100%, the wind speed is 5-7m / s, the temperature is set at 65°C and rises to 85°C in 5 hours, and the humidity is set at 10%. After sampling and testing, the free lead content, degree of dryness, strength of green board and average weight of a single piece of green board all meet the technical requirements.

[0021] The specific test results are shown in the table below:

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com