Cutting tube blank full automatic flat head chamfering machine

A fully automatic, chamfering machine technology, applied in the direction of drive devices, metal processing machinery parts, turning equipment, etc., can solve the problems of difficult to guarantee the machining accuracy of the shell, low processing efficiency, long processing hours, etc., to achieve dust and chip prevention performance Excellent, easy to adjust, good anti-chip performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

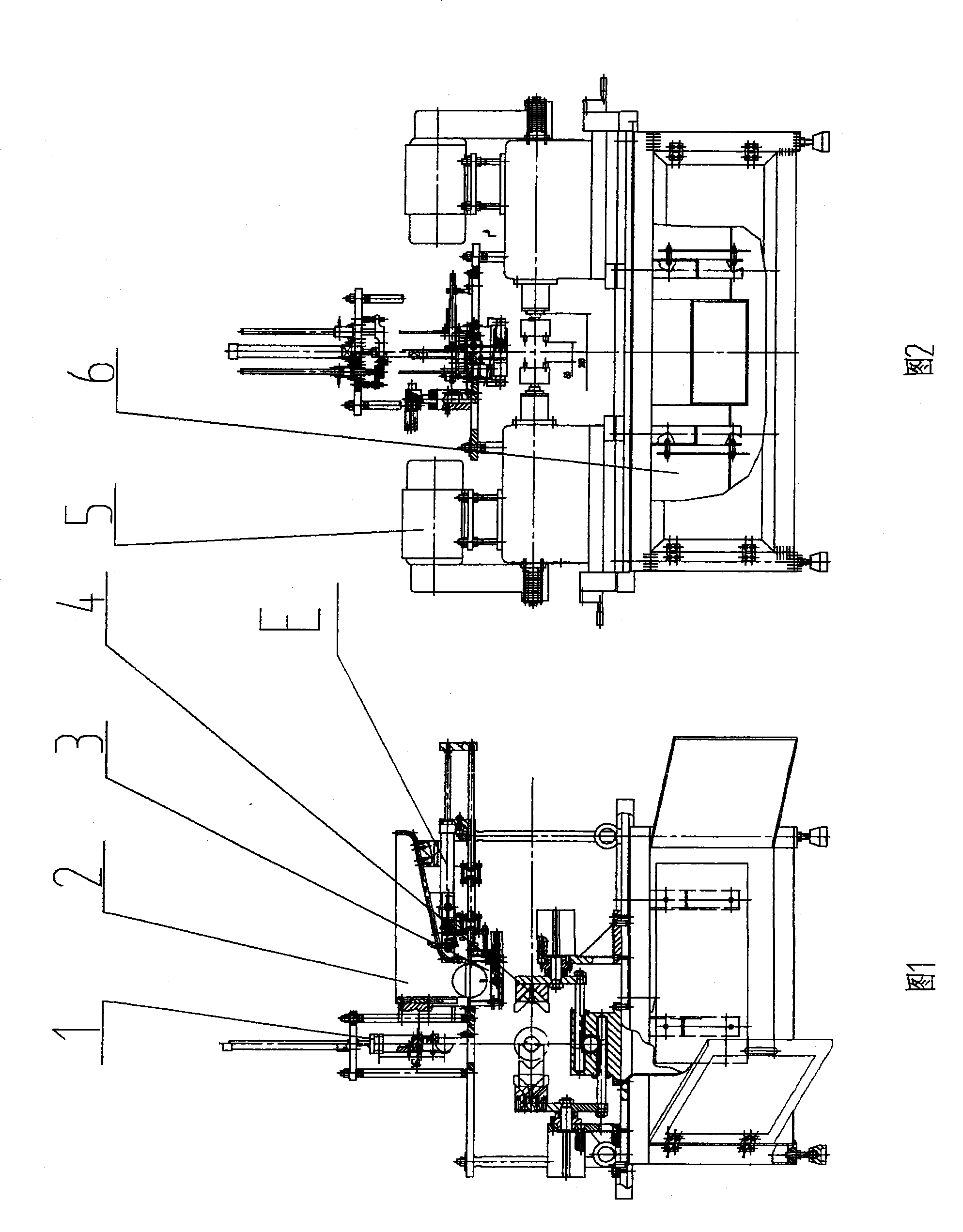

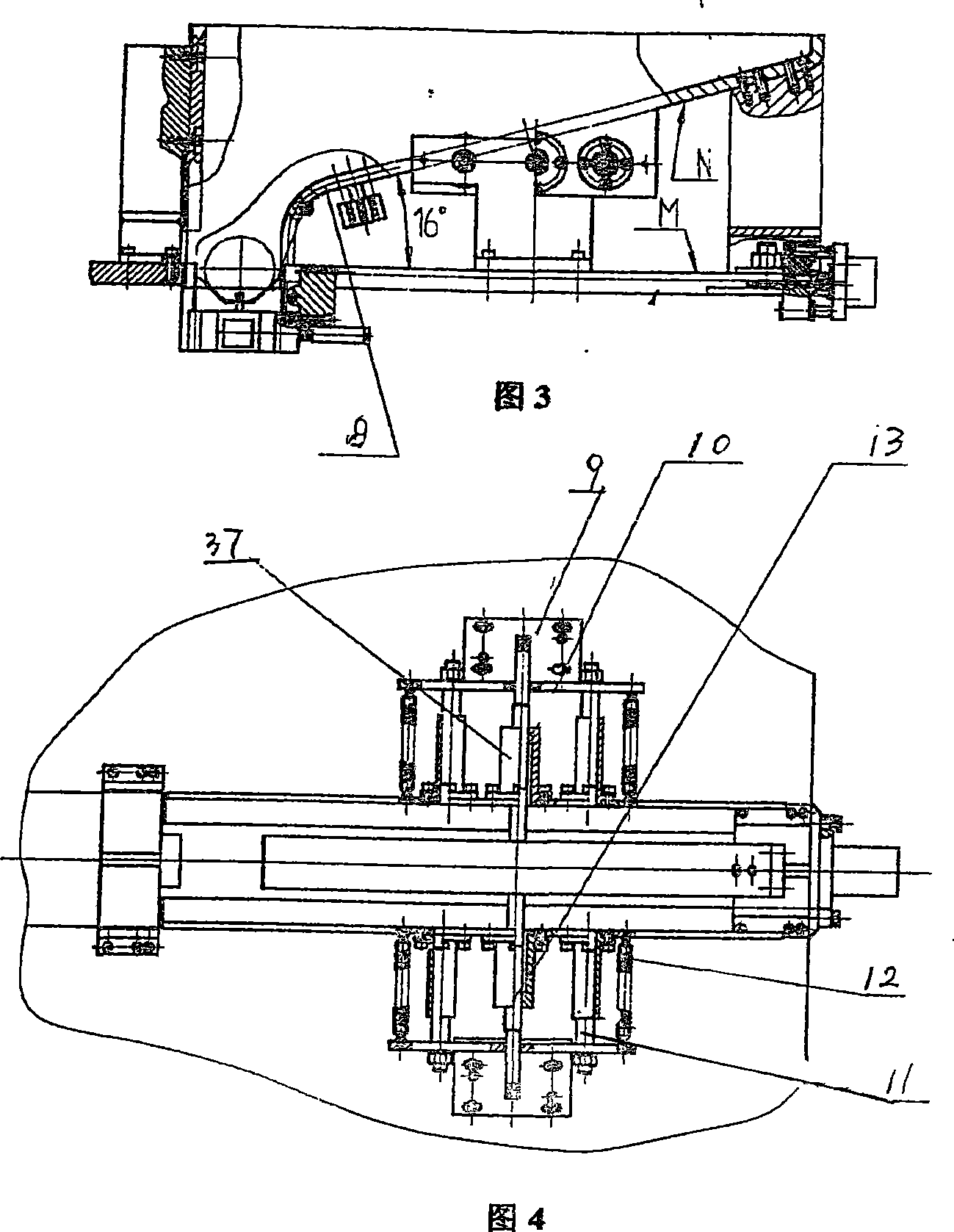

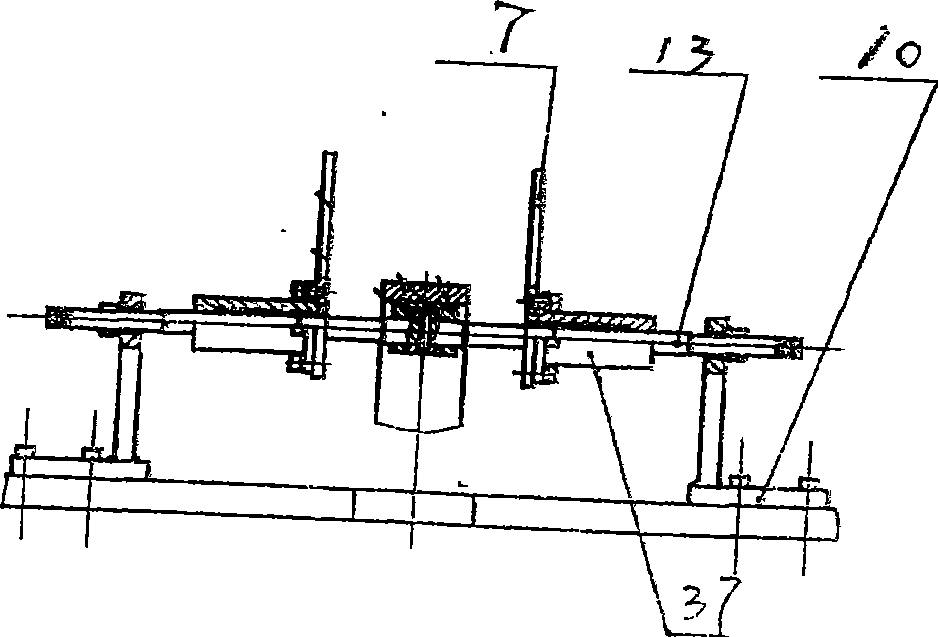

[0029] A fully automatic flat-head chamfering machine for cutting tube blanks, comprising: a vertical feeding manipulator 1, a base 6, a horizontal drive track device E, a feeding bin 2 mounted on the base 6, a horizontal feeding hopper 3, centering A clamping device 4, and a digitally controlled self-driving power head 5.

[0030] A digitally controlled self-driving power head, including: a motor 39, a housing 42, a carriage 43, and a speed measuring wheel 40 mounted on the first shaft sleeve 53. The speed measuring sensor 41 is connected to the housing 42 with threads and has an internal spline The first bearing 51 of the first shaft sleeve 53 is supported in the first shaft sleeve 53, and the bearing sleeve 52 is fixed with the housing 42 with screws, and the main shaft 44 is connected to the first shaft sleeve 53 with the spline at its right end. connection, its left end is connected with the second shaft sleeve 45 with the second bearing 63, bearing cap 59, nut 58 and scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com