Hydrant drilling bit and hydrant driller

A technology for a water drilling rig and a processing head, which is applied to metal processing equipment, machine tools suitable for grinding workpiece edges, and manufacturing tools, etc., can solve the problems of complex process, time-consuming and laborious, and high cost, achieve a sophisticated layout structure, and reduce production costs. , the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

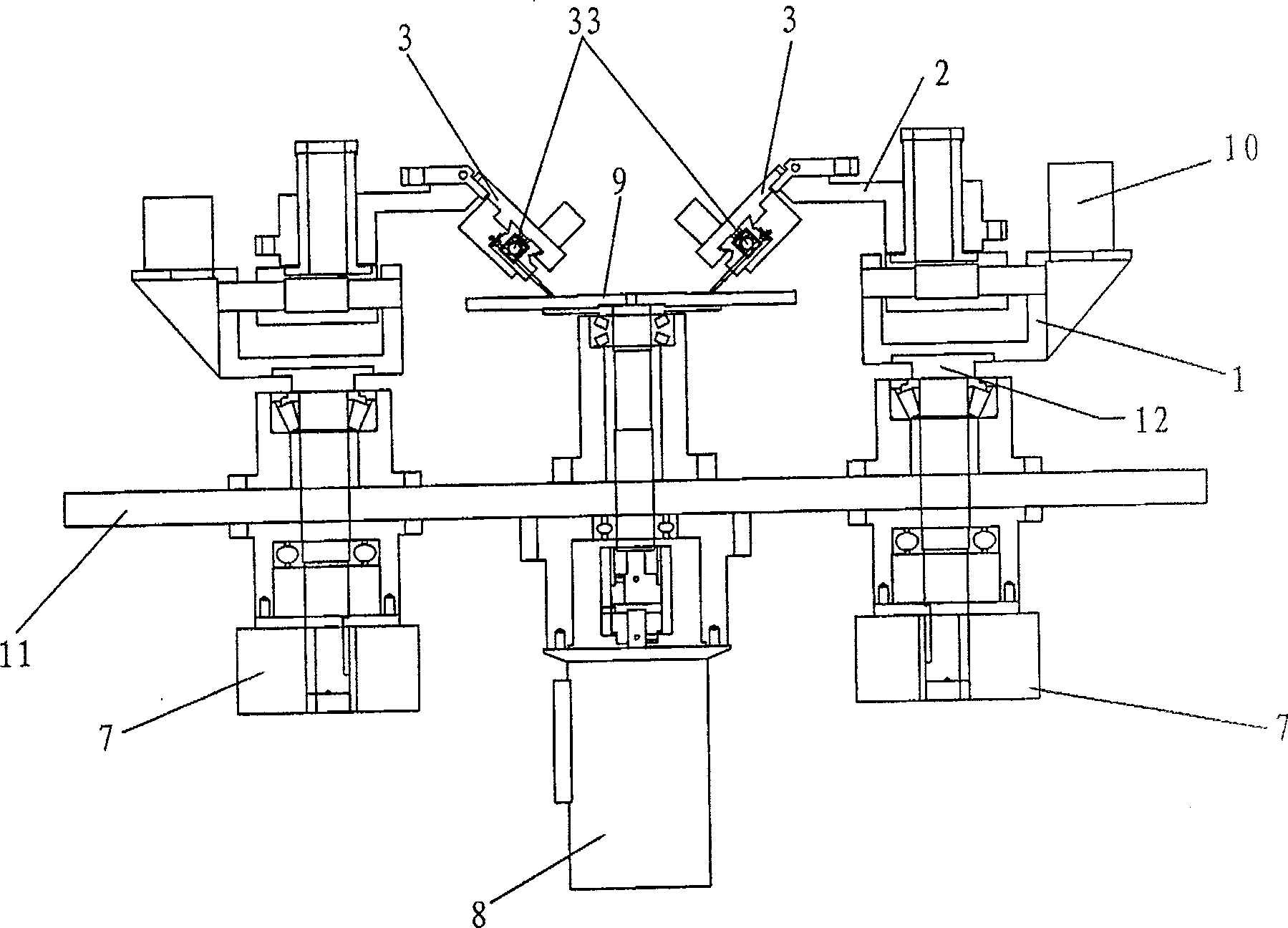

[0019] Below by embodiment and with reference to accompanying drawing, the present invention will be further described.

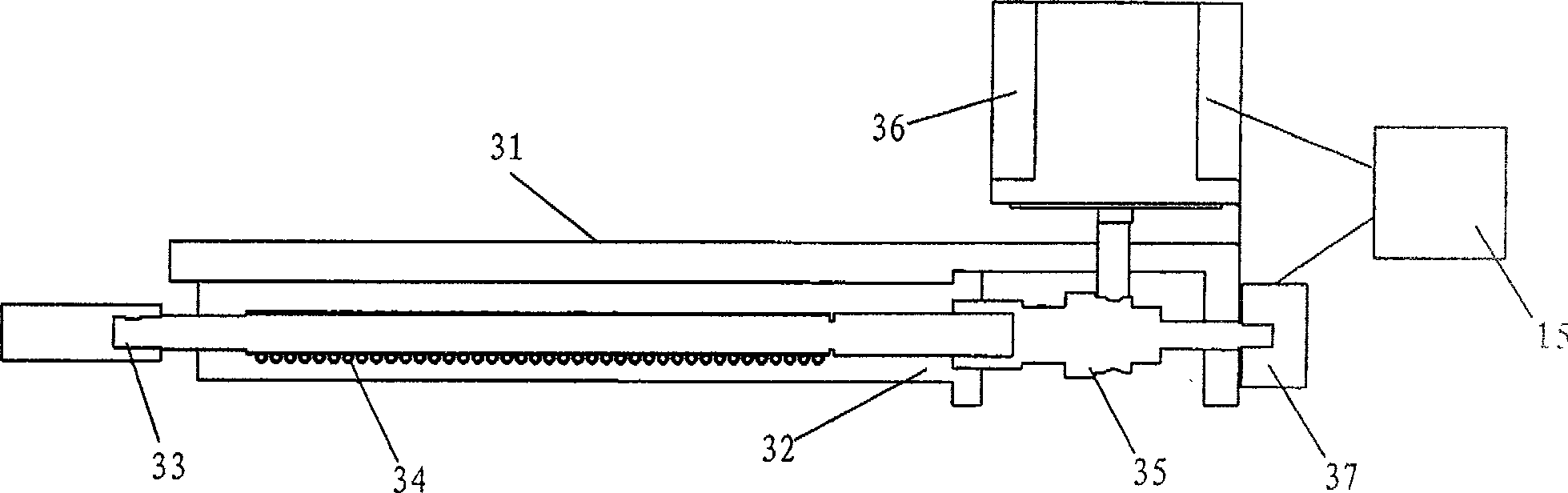

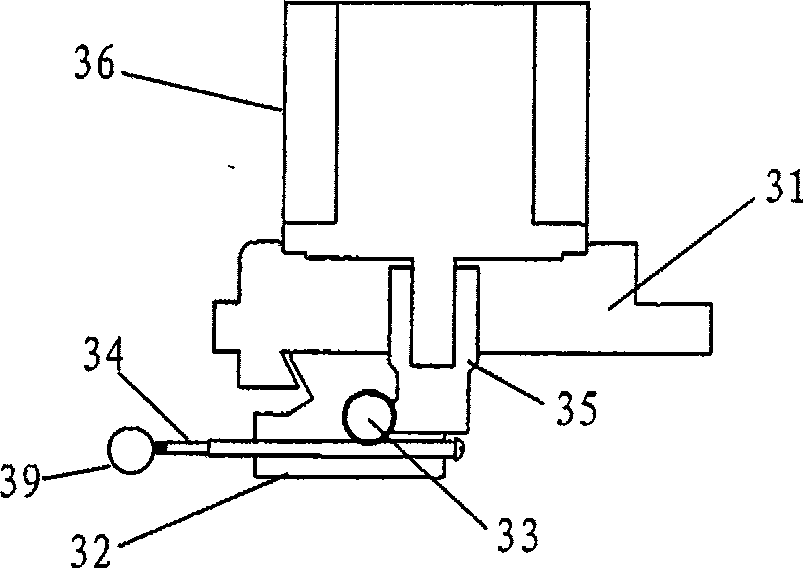

[0020] see figure 1 , figure 2 In the embodiment of the present invention, the rhinestone processing head 3 is provided with a clamp mounting plate 31, a housing 32, a clamp shaft 33, a clamp needle 34, a shaft coupling 35, a processing head stepping motor 36, and a signal collector 37. The housing 32 is installed on On the clamp mounting plate 31, the clamp shaft 33 is sleeved on the coupling 35, the clamp shaft 33 is connected with the clamp pin 34 in a worm gear mode and installed in the housing 32, the clamp (including the housing 32, the clamp shaft 33, the clamp pin 34) It can be loaded and unloaded freely. The processing head stepper motor 36 is installed on the fixture mounting plate 31 and connected with the shaft coupling 35 , and the signal collector 37 is connected with the shaft coupling 35 and used for reading the rotation angle signal of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com