Highly effective dephosphorizing denitrification combined type sewage treatment equipment

A sewage treatment device and combined technology, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc. Waste of land resources and other issues, to achieve the effect of efficient phosphorus and nitrogen removal sewage residence time, less land occupation, and lower circulation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

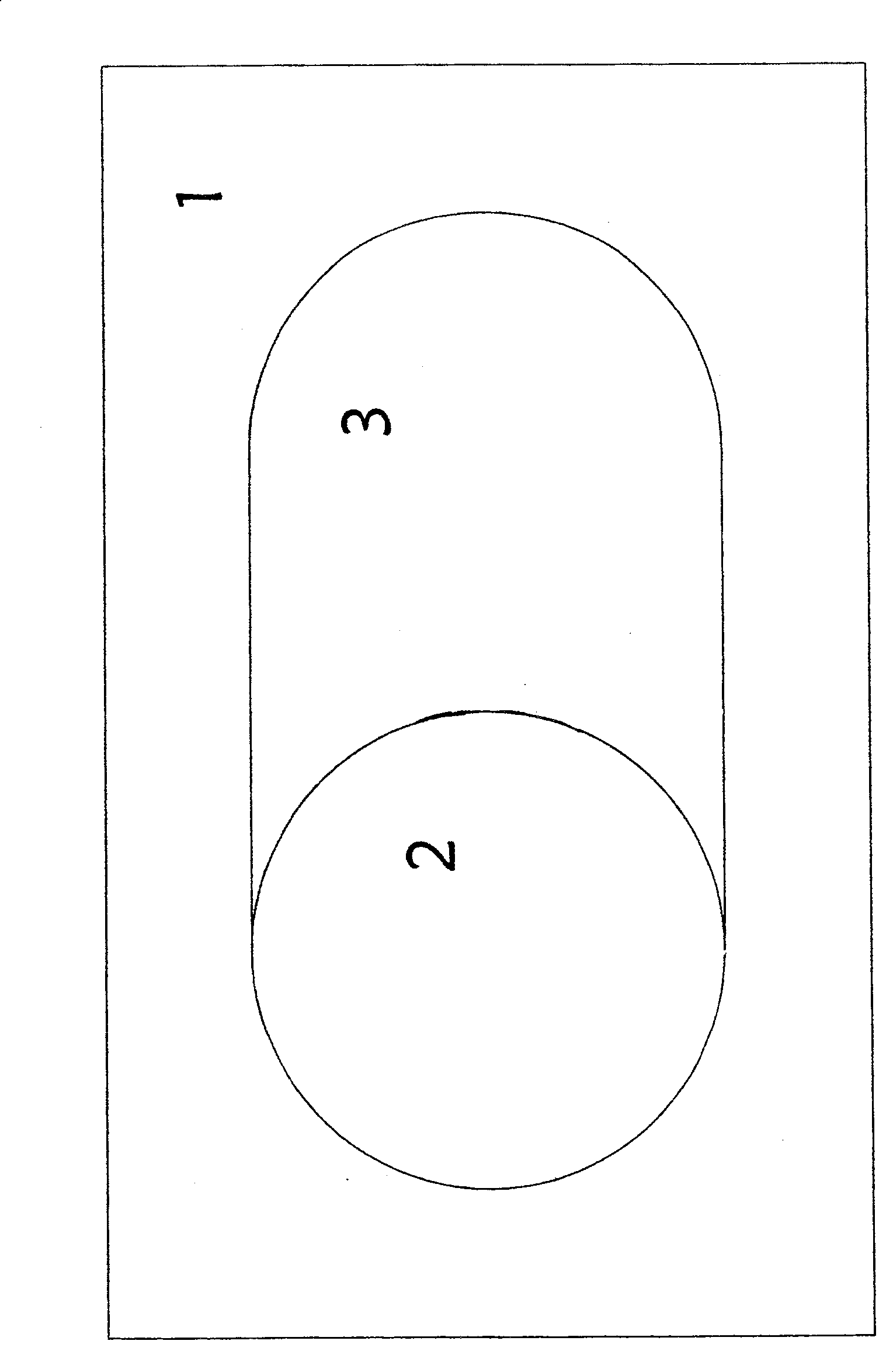

[0016] Example 1, a combined sewage treatment device for high-efficiency phosphorus and nitrogen removal, consisting of a rectangular pool body and an oval pool body, the oval pool body is located in the rectangular pool body, and the area formed by the inner wall of the rectangular pool and the outer wall of the oval pool It is set as aerobic tank 1, secondary settling tank 2, and anaerobic tank 3 are located in an oval pool body, which is formed by connecting two parallel straight walls and semicircular walls at both ends of the straight wall, and the oval pool body A circular secondary settling tank 2 is arranged at one end, and the circular secondary settling tank 2 shares a semicircular wall with the elliptical pool body, and the elliptical pool body outside the secondary settling tank 2 is designed as an anaerobic tank 3. And the aerobic pool operates under AO conditions.

Embodiment 2

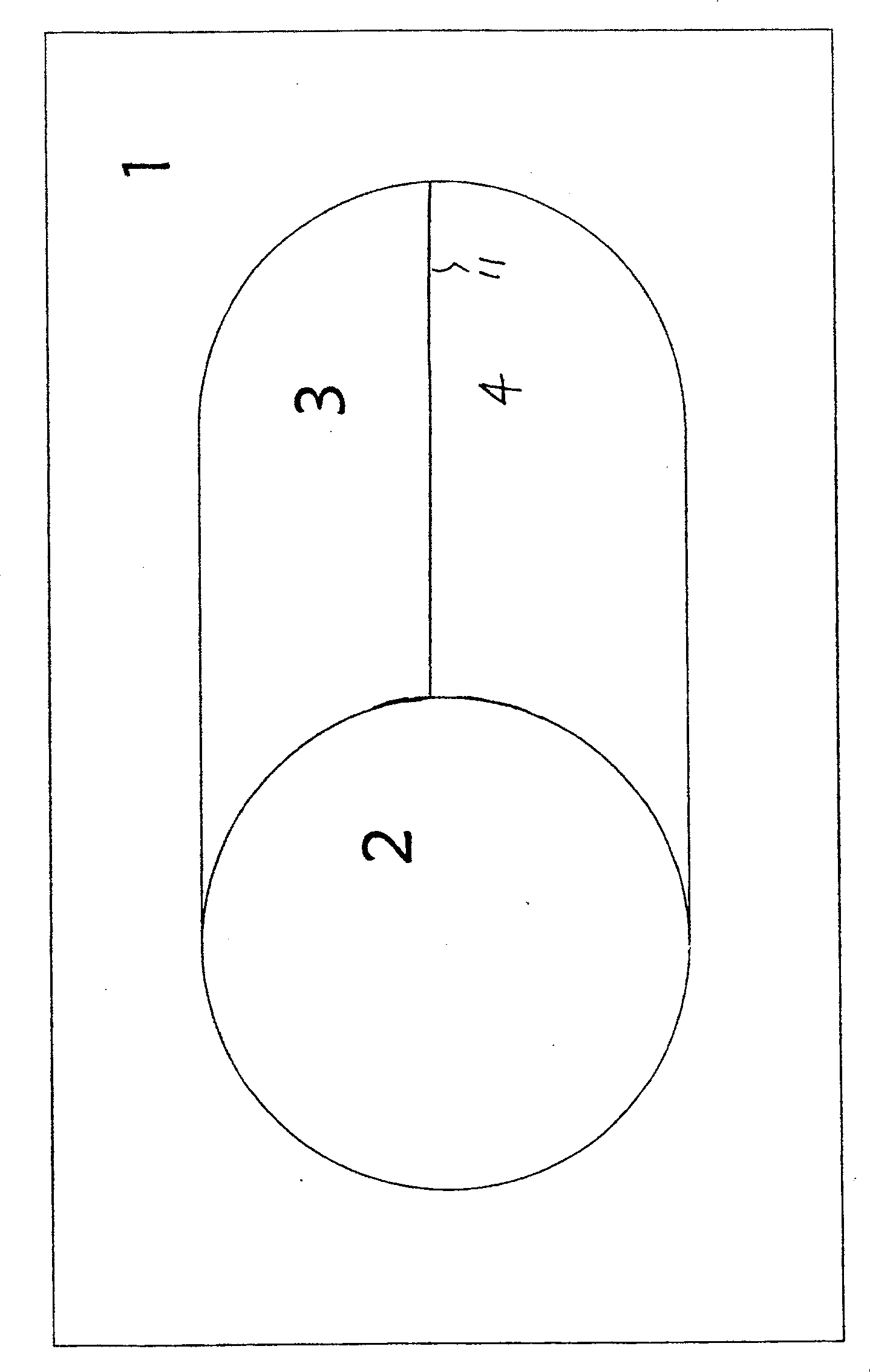

[0017] Example 2, a combined sewage treatment device for high-efficiency dephosphorization and denitrification, consisting of a rectangular pool body and an oval pool body, the oval pool body is located in the rectangular pool body, and the area formed by the inner wall of the rectangular pool and the outer wall of the oval pool It is set as aerobic tank 1, secondary settling tank 2, anaerobic tank 3, and anoxic tank 4 are set in an oval pool body, which is formed by connecting two parallel straight walls and semicircular walls at both ends of the straight walls A circular secondary settling tank 2 is arranged at one end of the oval pool body, the circular secondary settling tank 2 shares a semicircular wall with the oval pool body, and a middle Partition wall 11, the two areas formed by the middle partition wall 11, the inner wall of the elliptical tank, and the outer wall of the secondary settling tank 2 are respectively arranged as the anaerobic tank 3 and the anoxic tank 4....

Embodiment 3

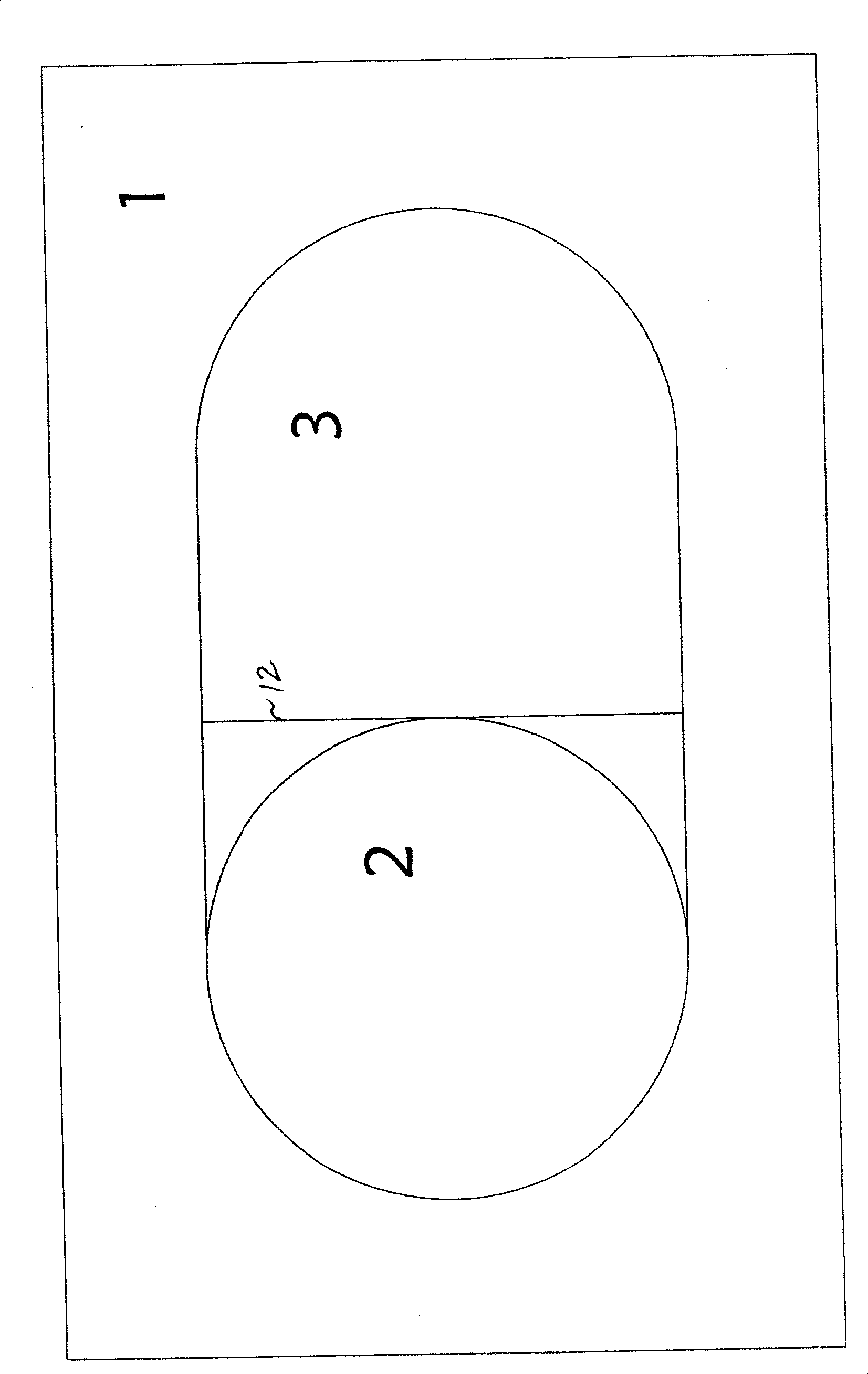

[0018] Embodiment 3, referring to Embodiment 1, a partition wall 12 is arranged between the two straight walls of the elliptical tank body, and the partition wall 12 is tangent to the outer wall of the secondary settling tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com