Polygonal counterflow type cooling tower

A polygonal cooling tower technology, applied in the field of cooling tower equipment, can solve the problems of difficult assembly, inconvenient transportation, high processing and manufacturing costs, and achieve the effects of reducing manufacturing costs, facilitating transportation and handling, and reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

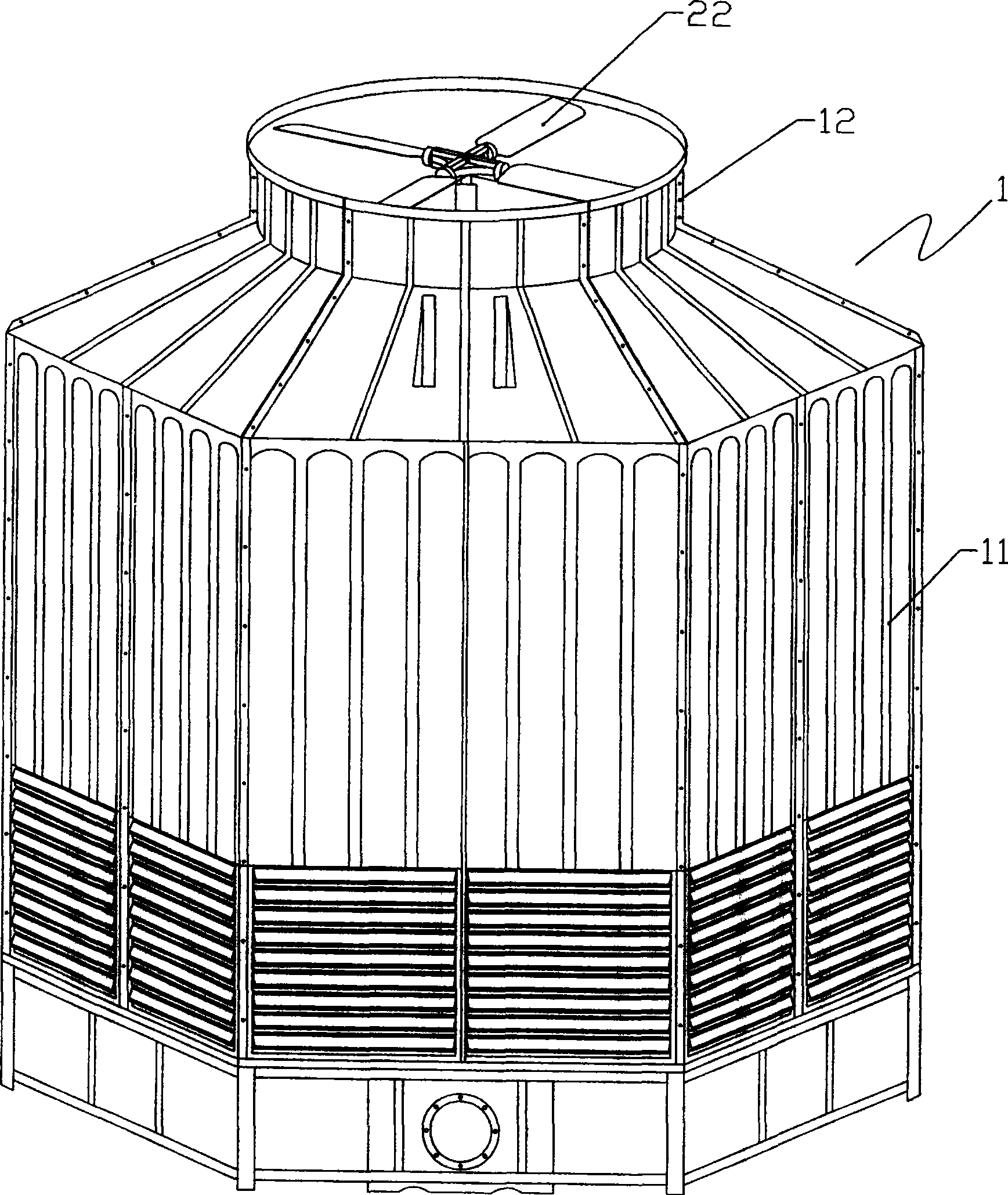

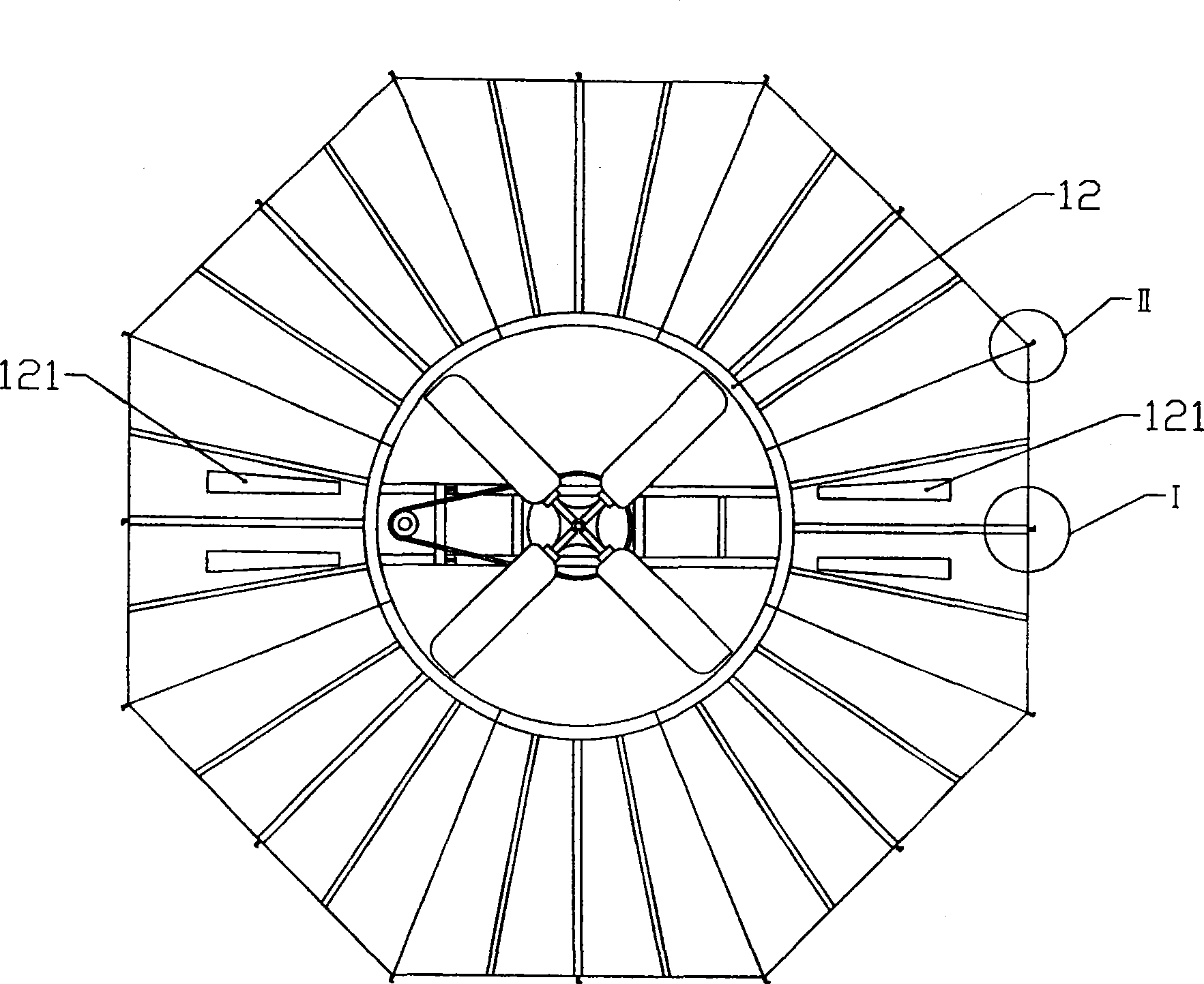

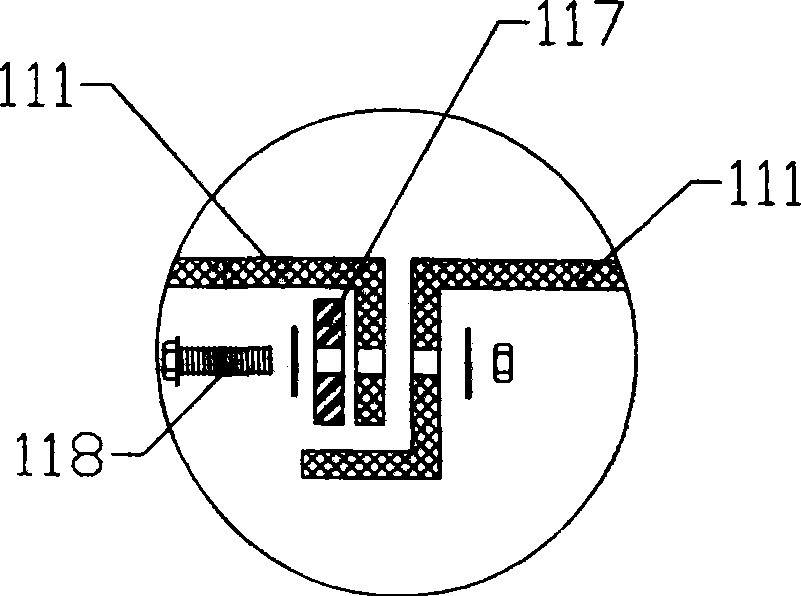

[0032] Such as figure 1 , shown in Fig. 3 (a), Fig. 3 (b), the polygonal counter-flow type cooling tower of the present invention comprises tower body 1, and described tower body 1 is by tower body 11, and the air duct 12 that is connected with tower body top, And form with the water storage basin 13 that is connected with the tower body bottom. Wherein: the both sides of described blower 12 are provided with the groove 121 that is used for fixing motor mounting frame, and fan 22 and motor 23 are installed on motor mounting frame 21, when installing, put the two ends of motor mounting frame 21 on described In the grooves 121 on both sides of the air duct, the middle part of the motor installation frame 21 is connected with the central throat 15 through the support frame 24 , and the motor 23 is installed on the motor installation frame 21 and placed under the fan 22 .

[0033]The tower body 1 is provided with a central throat 15, the upper end of the central throat 15 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com