Process for preparing large cast steel support roller

A preparation process and technology of back-up rolls, applied in the field of advanced preparation technology of cast steel back-up rolls, can solve the problems of scrapped roll castings, difficulty in removal, deep cracks, etc., achieve stable casting process, improve casting qualification rate, and enhance feeding capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

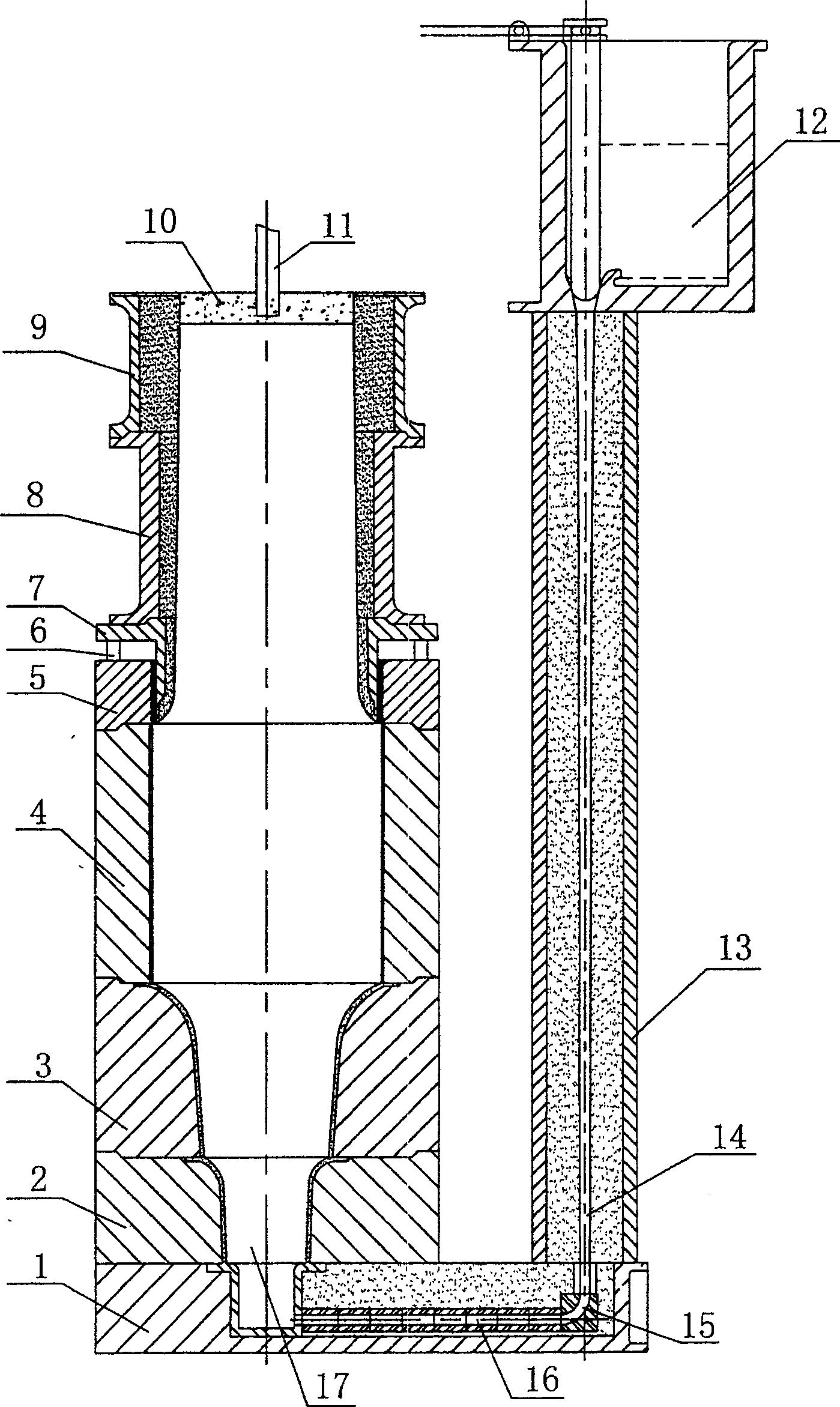

[0031] The material of the present embodiment is 40Cr4, the weight of pouring molten metal is 44 tons, and the pouring speed is 8 tons per minute. Its casting process is as follows:

[0032] 1) The tangential ingate rotary pouring technology is adopted, and the sprue cup and pouring system are designed according to the principle of smooth filling.

[0033] 2) The sliding roll neck technology is adopted, and the gap between the sliding roll neck outer cover 5 and the sliding roll neck inner cover 7 is 5mm.

[0034] 3) The electric heating riser is used, the diameter of the riser is 900mm, and the electroslag is Al 2 o 3 , CaO and CaF 2 A mixture of, by weight, Al 2 o 3 40%, CaO 10%, CaF 2 50%. The current is 800A, the voltage is 125V, the heating power is 100kw, and the heating time is 11h.

[0035] 4) The sprue and runner are formed with refractory brick tubes.

[0036] The first pour was successfully completed. After 20 minutes of pouring, the sliding roll neck pad ...

Embodiment 2

[0038] The material of this embodiment is 40Cr4, the weight of pouring molten metal is 46 tons, and the pouring speed is 10 tons per minute. Its casting process is as follows:

[0039] 1) The tangential inner gate rotary pouring technology is still used, and the sprue cup and pouring system are designed according to the principle of smooth filling.

[0040] 2) The sliding roll neck technology is adopted, and the gap between the outer wall of the sliding roll neck inner sleeve 7 and the inner wall of the sliding roll neck outer sleeve 5 is 10 mm.

[0041] 3) The electric heating riser is adopted, the diameter of the riser is 950mm, and the electroslag is Al 2 o 3 , CaO and CaF 2 A mixture of, by weight, Al 2 o 3 50%, CaO 15%, CaF 2 35%. The current is 700A, the voltage is 100V, the heating power is 70kw, and the heating time is 12h.

[0042] 4) The sprue and runner are formed with refractory brick tubes.

[0043] The second pour was successfully completed. The sliding...

Embodiment 3

[0045] The material of the present embodiment is 40Cr4, the weight of pouring molten metal is 45 tons, and the pouring speed is 9 tons per minute. Its casting process is as follows:

[0046] 1) The tangential ingate rotary pouring technology is still used, and the sprue cup and pouring system are designed according to the principle of smooth filling.

[0047] 2) The sliding roll neck technology is adopted, and the gap between the outer wall of the sliding roll neck inner sleeve 7 and the inner wall of the sliding roll neck outer sleeve 5 is 8mm.

[0048] 3) The electric heating riser is used, the diameter of the riser is 1000mm, and the electroslag is Al 2 o 3 , CaO and CaF 2 A mixture of, by weight, Al 2 o 3 70%, CaO 10%, CaF 2 20%. The current is 1000A, the voltage is 150V, the electric heating power is 150kw, and the heating time is 10h.

[0049] 4) The sprue and runner are formed with refractory brick tubes.

[0050] The third pouring was successfully completed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com