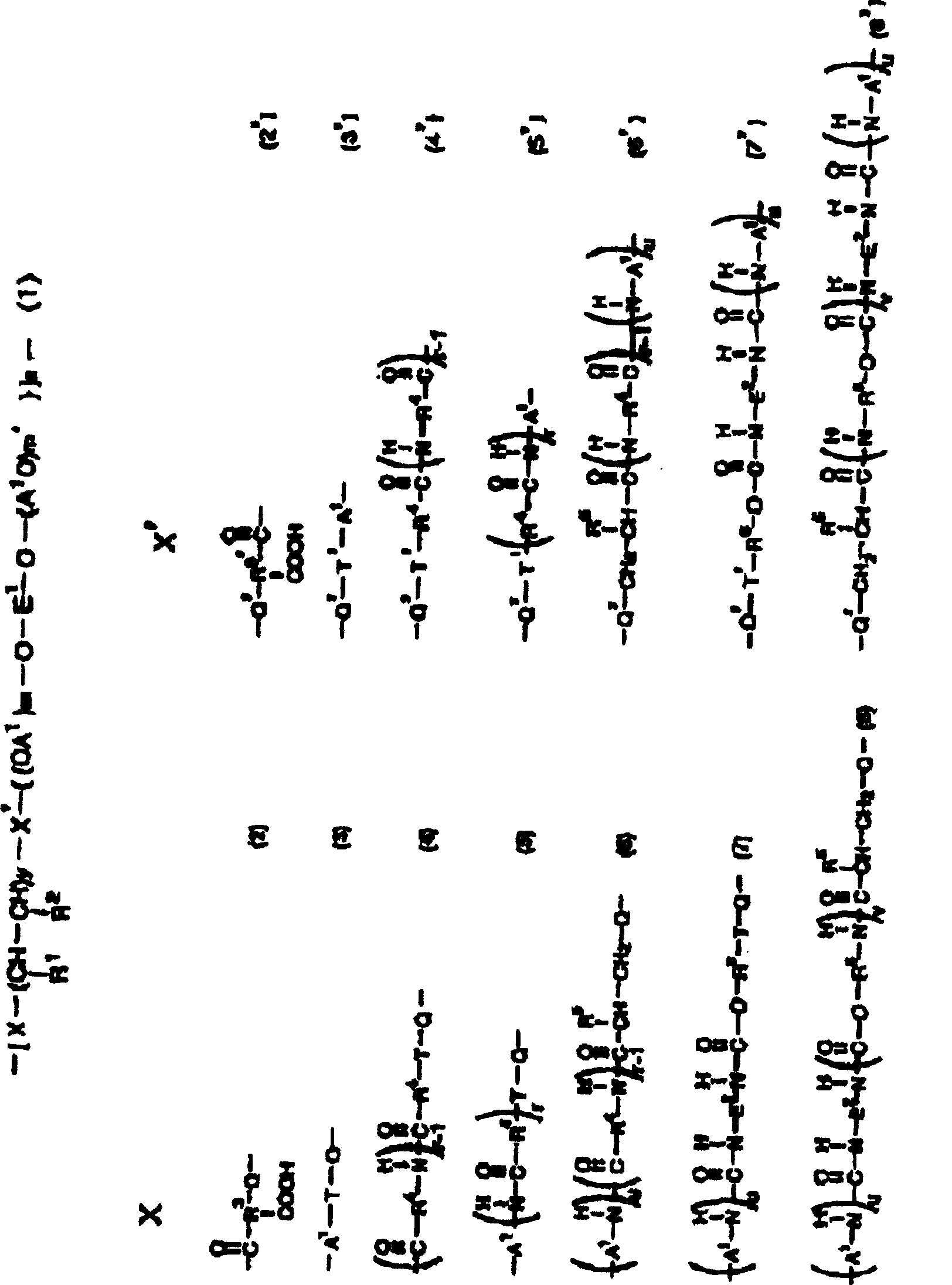

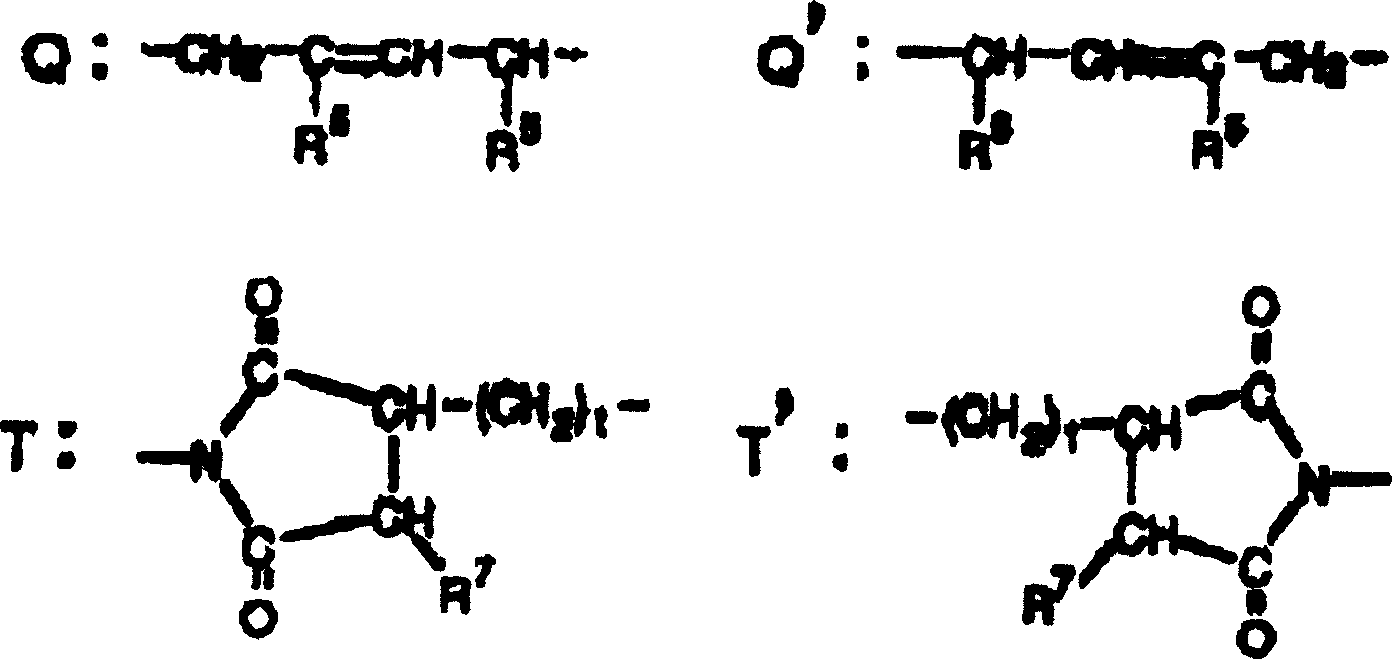

Polyolefin resin foam and manufacturing method thereof

A technology of polyolefin resin and manufacturing method, which is applied in the field of polyolefin resin foam and its manufacturing, can solve the problems such as difficult to show antistatic effect, pollution, and stickiness, and achieve good appearance, high independent cell rate, and apparent The effect of low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0198] As polyolefin resin, with respect to 100 weight parts of PE1 (low-density polyethylene), mix 2 weight parts of air cell regulator masterbatch, with respect to 100 weight parts of low-density polyethylene, add polymer type antistatic agent P1 [Pelestat 300 ] 6.4 parts by weight, supplied from the raw material inlet of an extruder with an inner diameter of 90 mm, heated and kneaded, and turned into an adjusted resin melt at about 200° C. Mixed butane of 70% by weight of n-butane and 30% by weight of isobutane was pressurized into the above resin melt so as to be 25 parts by weight relative to 100 parts by weight of low-density polyethylene. The extruder of diameter 120mm that is connected to the downstream side of the extruder of above-mentioned diameter 90mm supplies resin melt again, and the foaming temperature of the polyolefin resin melt after regulating cooling is 110 ℃, and die head pressure is 7~10MPa ( G) to become a foamable polyolefin resin melt, and the foamabl...

Embodiment 2

[0200] A foamed sheet was obtained in the same manner as in Example 1, except that PE2 (low-density polyethylene) was used as the main raw material for the polyolefin resin, the compounding amount of mixed butane was adjusted to 27 parts by weight, and the foaming temperature was 108°C.

Embodiment 3

[0202] Except that the blending amount of the physical foaming agent was 23 parts by weight, 4.7 parts by weight of P1 [Pelestat 300] was added as a polymer antistatic agent, and the foaming temperature was adjusted to 111° C., the rest was the same as in Example 1 to obtain a foamed sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tension | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com