Method for reducing friction between piston and cylinder wall of internal-combustion engine, and Oil saving piston

A technology of internal combustion engine cylinders and pistons, applied in the directions of pistons, mechanical equipment, engine components, etc., can solve the problems of reducing the amount of lubricating oil, increasing the gap between the piston and the cylinder, increasing the vibration and noise of the engine, and achieving increased power output, The effect of reducing fuel consumption and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

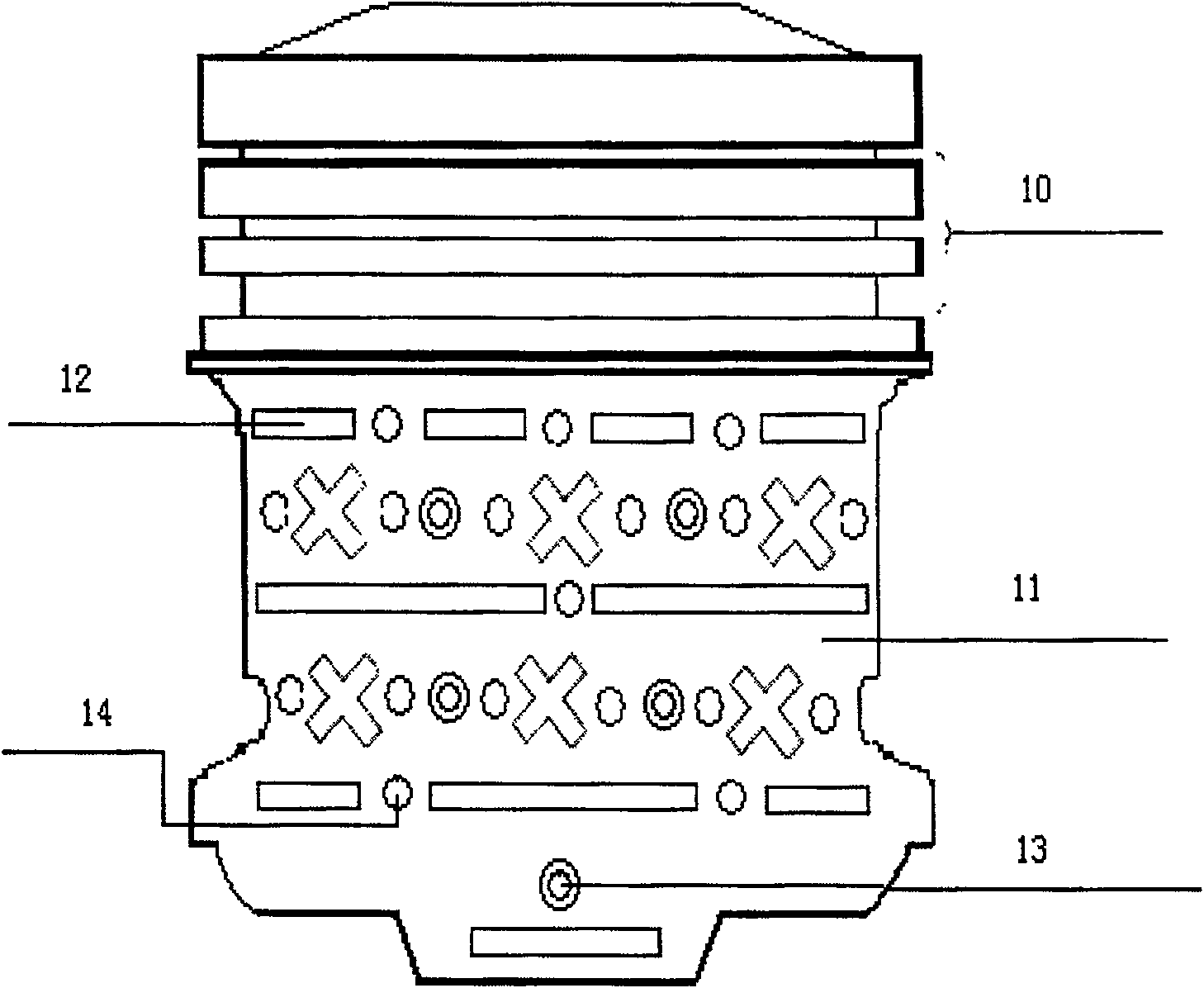

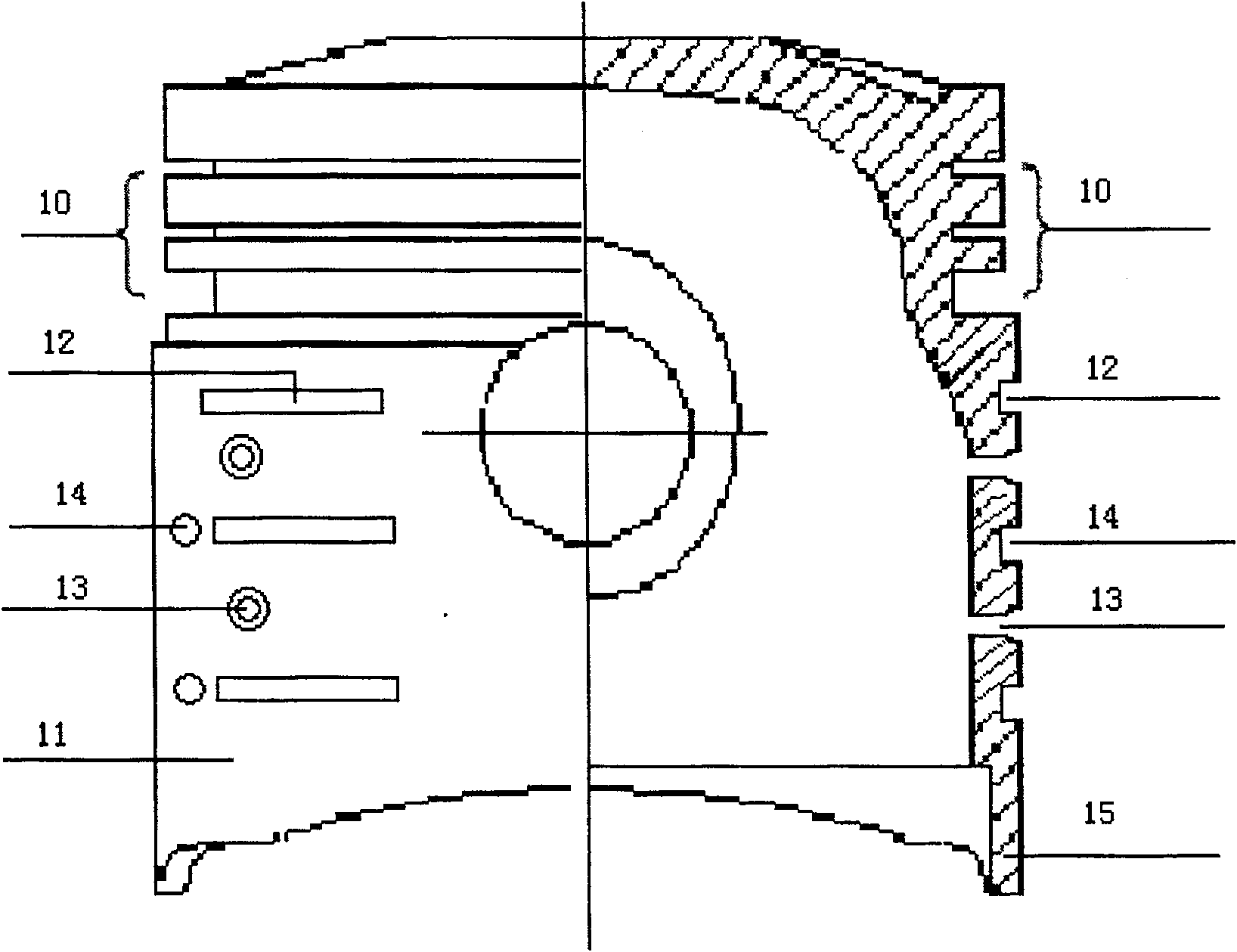

[0026] figure 1 , 2 Shown is the front view and cross-sectional view of the pistons of Embodiments 1 and 2 of the present invention.

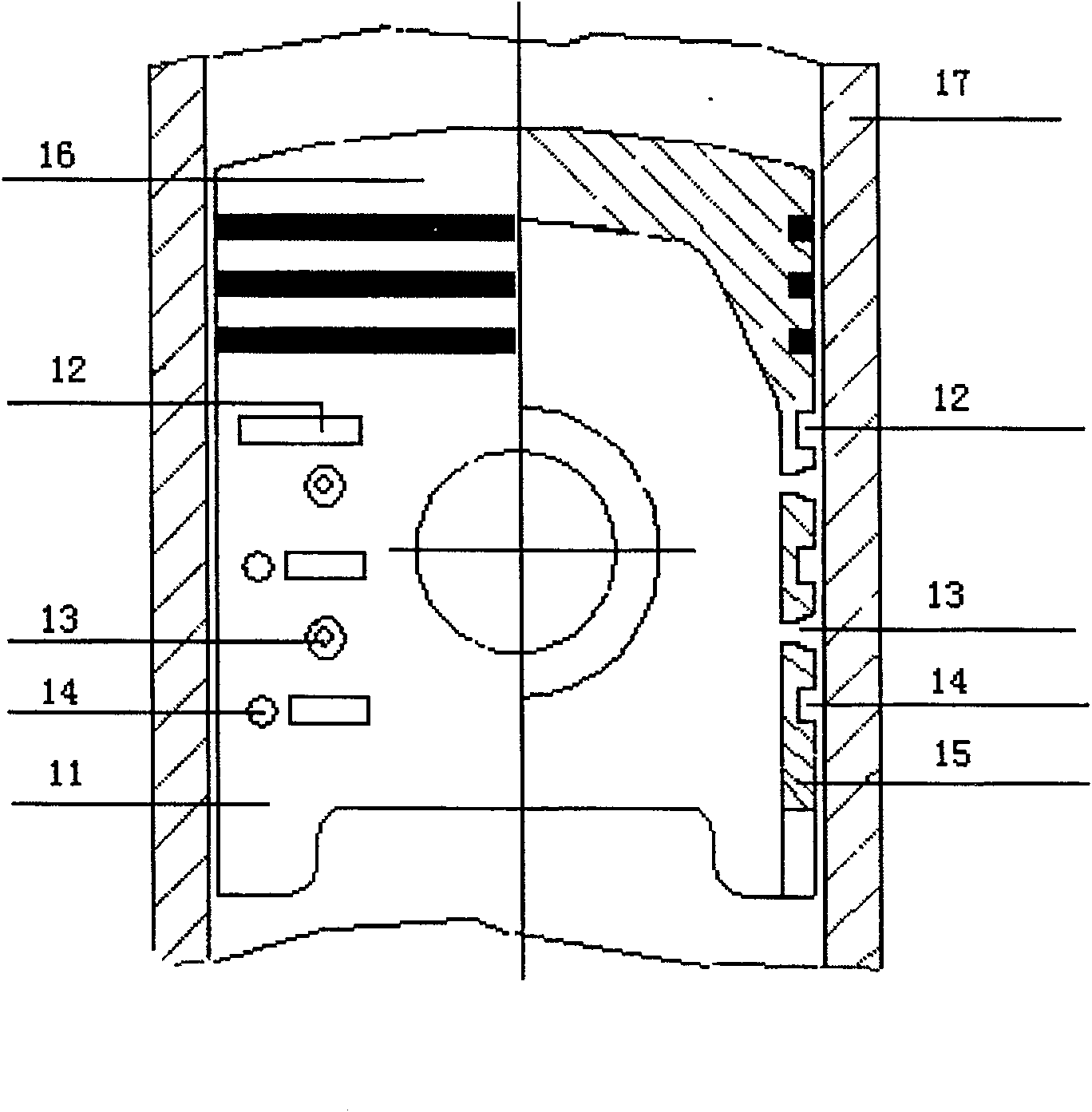

[0027] image 3 The illustrated embodiment 1 and 2 of the present invention. When the internal combustion engine is working, the piston 16 reciprocates at a high speed in the cylinder wall 17, continuously guides the lubricating oil through the through hole 13 of the piston skirt and quickly flows into the surface of the piston skirt 11, and stores the lubricating oil in the recess provided on the piston skirt. Groove 12 and the non-through hole 14 that this piston skirt portion is provided with, so that between this internal combustion engine cylinder wall 17 and this piston skirt portion 11 surface, distribute enough lubricating oil all the time, and isolated internal combustion engine cylinder wall 17 and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com