Microwave dielectric ceramic with low loss and low temperature coefficient of frequency and its prepn

A microwave dielectric ceramic and temperature coefficient technology, applied in ceramics, inorganic insulators, etc., can solve the problems of volatile material density, high ceramic sintering temperature, uneven microscopic distribution of raw materials, etc., and achieve the effect of expanding the selection range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

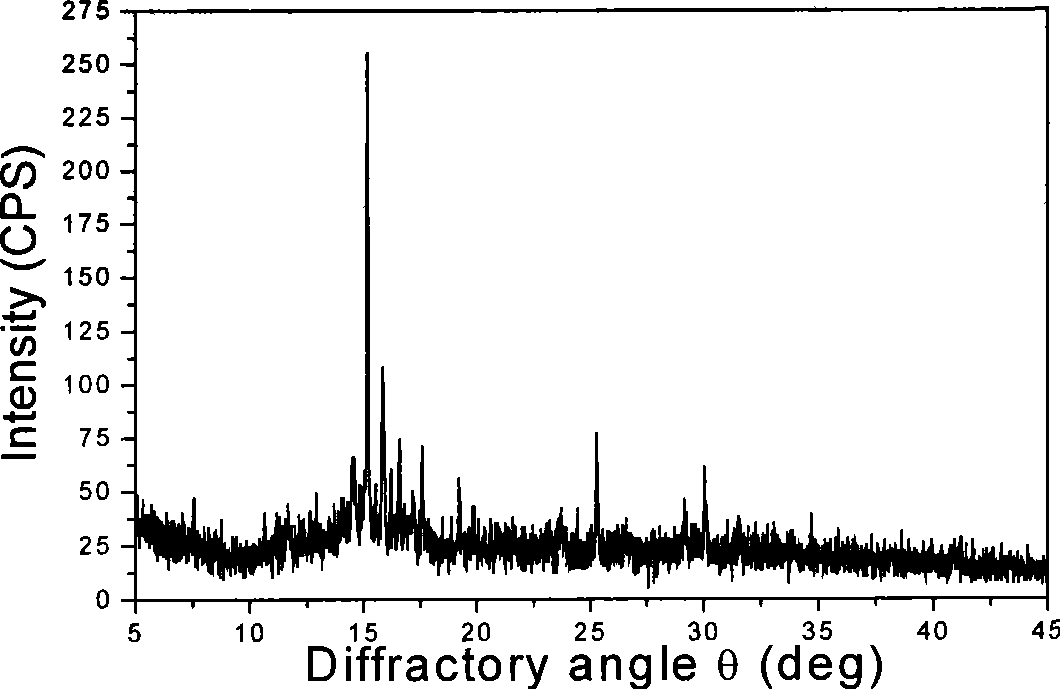

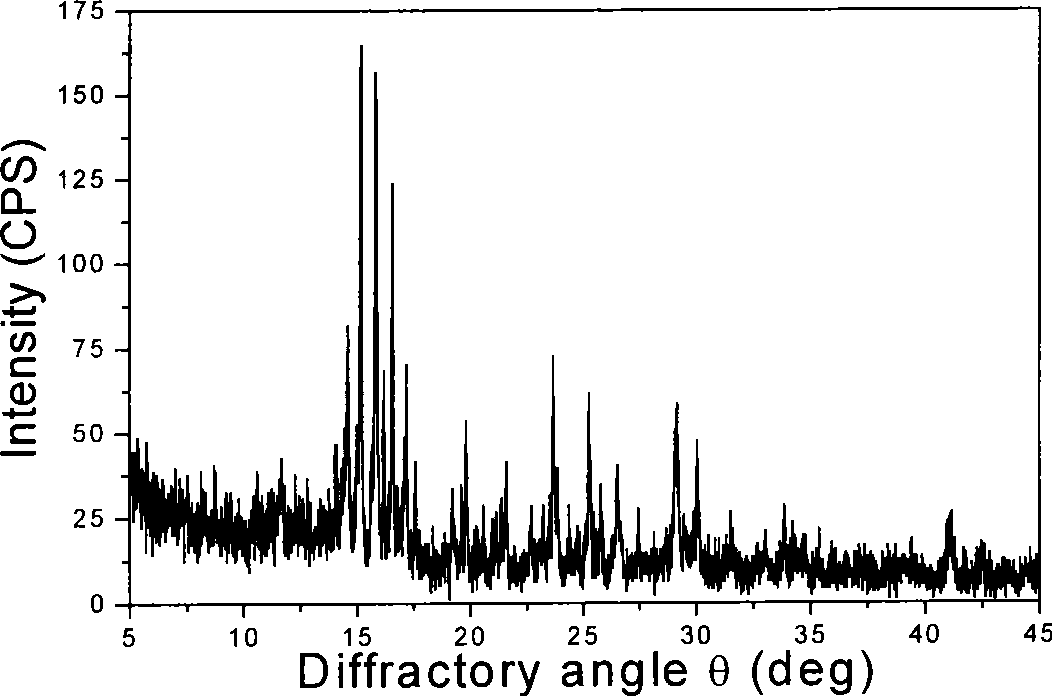

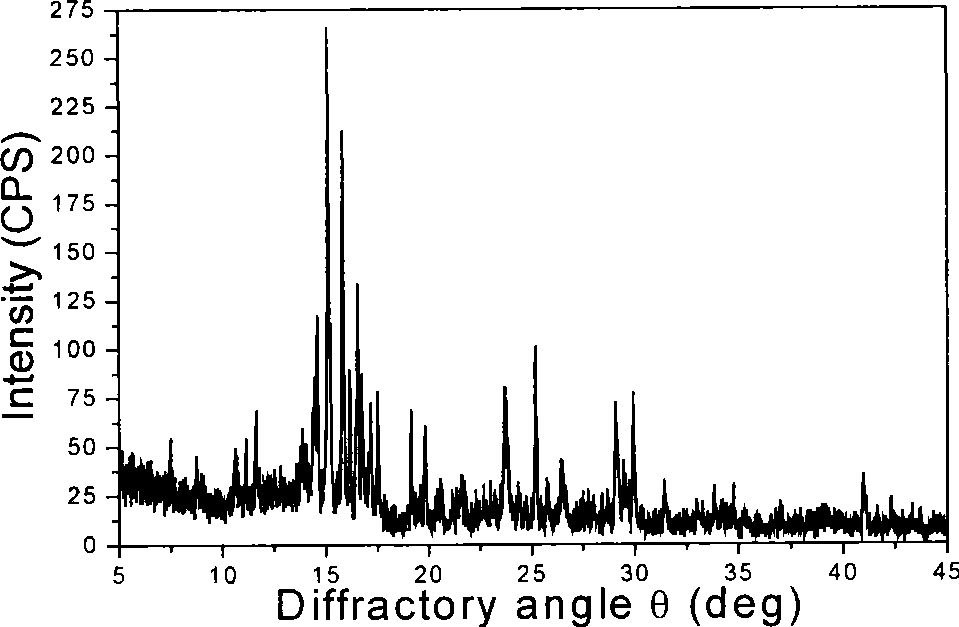

Image

Examples

Embodiment 1

[0045] Weigh the raw materials according to the formula molecular formula: x = 0.1 and y = 0.2 in the designed molecular formula. The molecular formula is Ba 5.7 (Nd 0.2 , Eu 0.8 ) 8.2 Ti 18 O 54 , The molecular weight is 3742.3698, the ingredient mass is 623.73g, and the number of moles of ingredient is 0.17;

[0046] Weigh the required raw material BaCO 3 The mass is 189.37g; Eu 2 O 3 The mass is 192.4g, (C 4 H 9 O) 4 Ti mass is 1041.92g and Nd 2 O 3 The mass is 45.98g.

[0047] The preparation method is:

[0048] Prepare 0.17 moles of Ba 5.7 (Nd 0.2 , Eu 0.8 ) 8.2 Ti 18 O 54 , Need 3.4 moles of EDTA acid, take 4.25 liters of 25%-28% ammonia water, add EDTA acid to the ammonia solution, and add the designed amount of butyl titanate, adjust the pH to 3 with nitric acid at 60℃~100℃ ~5, heat preservation and stirring to dissolve; add nitric acid to the europium oxide and neodymium oxide, and stir until the europium oxide and neodymium oxide are completely dissolved, generating euro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap