Method for etching complex pattern on 3-D abnormal curved surface

A special-shaped curved surface and pattern technology, applied in the field of photochemical processing, can solve the problems that cannot be applied to three-dimensional special-shaped curved surface complex pattern corrosion processing, and can not solve the problem of proper overlay of photographic negatives, so as to achieve good production effect and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

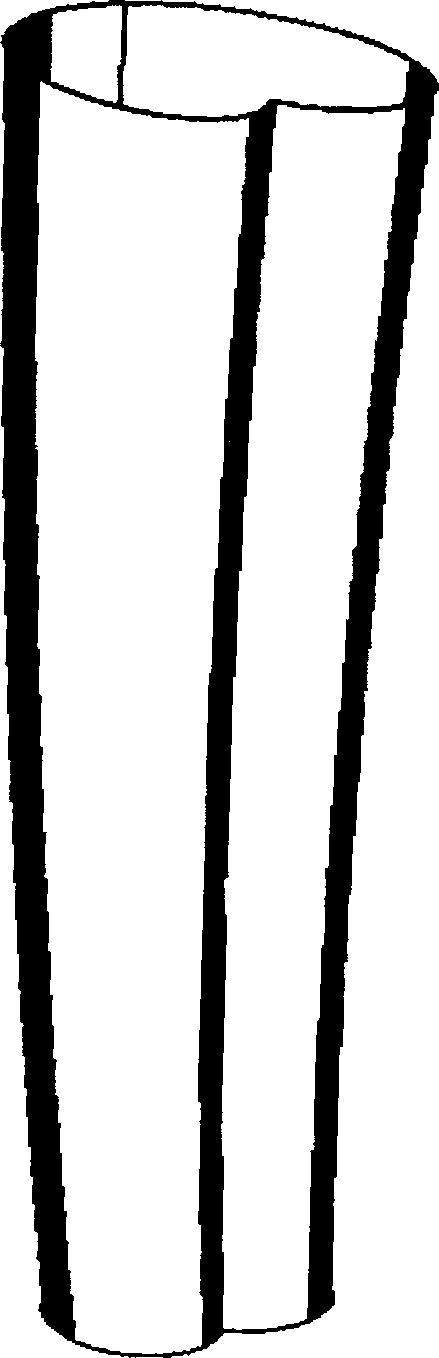

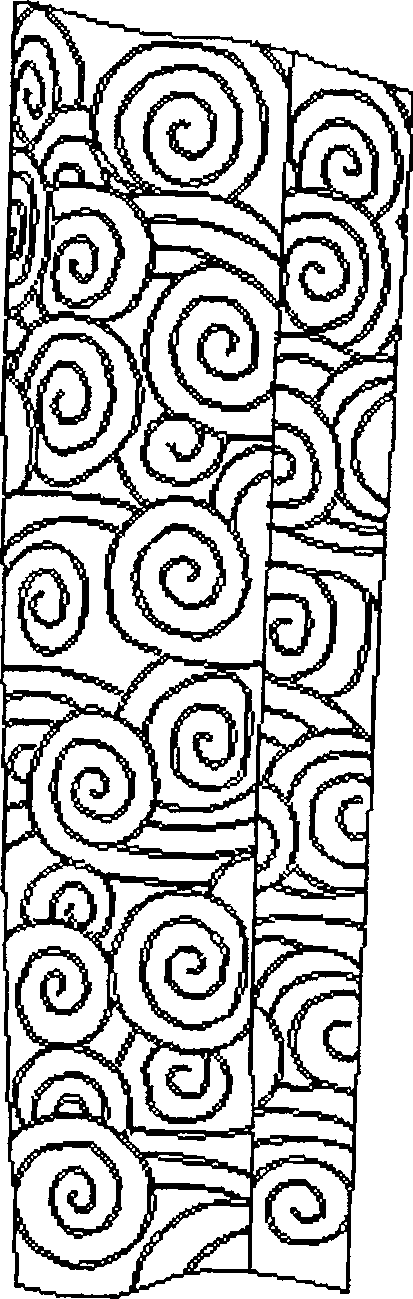

[0019] This embodiment requires the method of corroding complex patterns on three-dimensional special-shaped curved surfaces figure 1 Etched out on the three-dimensional shaped surface shown figure 2 As shown in the complex pattern, the surface of the workpiece's heart-shaped cross-section curved cone cylinder constitutes a three-dimensional special-shaped surface.

[0020] In order to solve this difficult problem that cannot be solved by traditional photochemical processing technology, the applicant has taken three corresponding effective measures after trial and error: 1. In order to ensure the flexibility and ductility of the pattern, the film pattern is exposed twice by photography. The method of imaging on the photosensitive plastic film; 2. When the patterned plastic film is attached to the photosensitive adhesive, in order to facilitate adjustment and attachment, a layer of special grease is applied between the two, so as to play a certain role. Full of concave and ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com