Method for treating waste water of 1,4-butanediol production

A technology for production wastewater and treatment method, applied in 1 field, can solve the problems of large floor space, insignificant treatment effect, and many control points, so as to ensure continuity and stability, avoid pollution of water sources or rivers, and be easy to manage and maintain. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

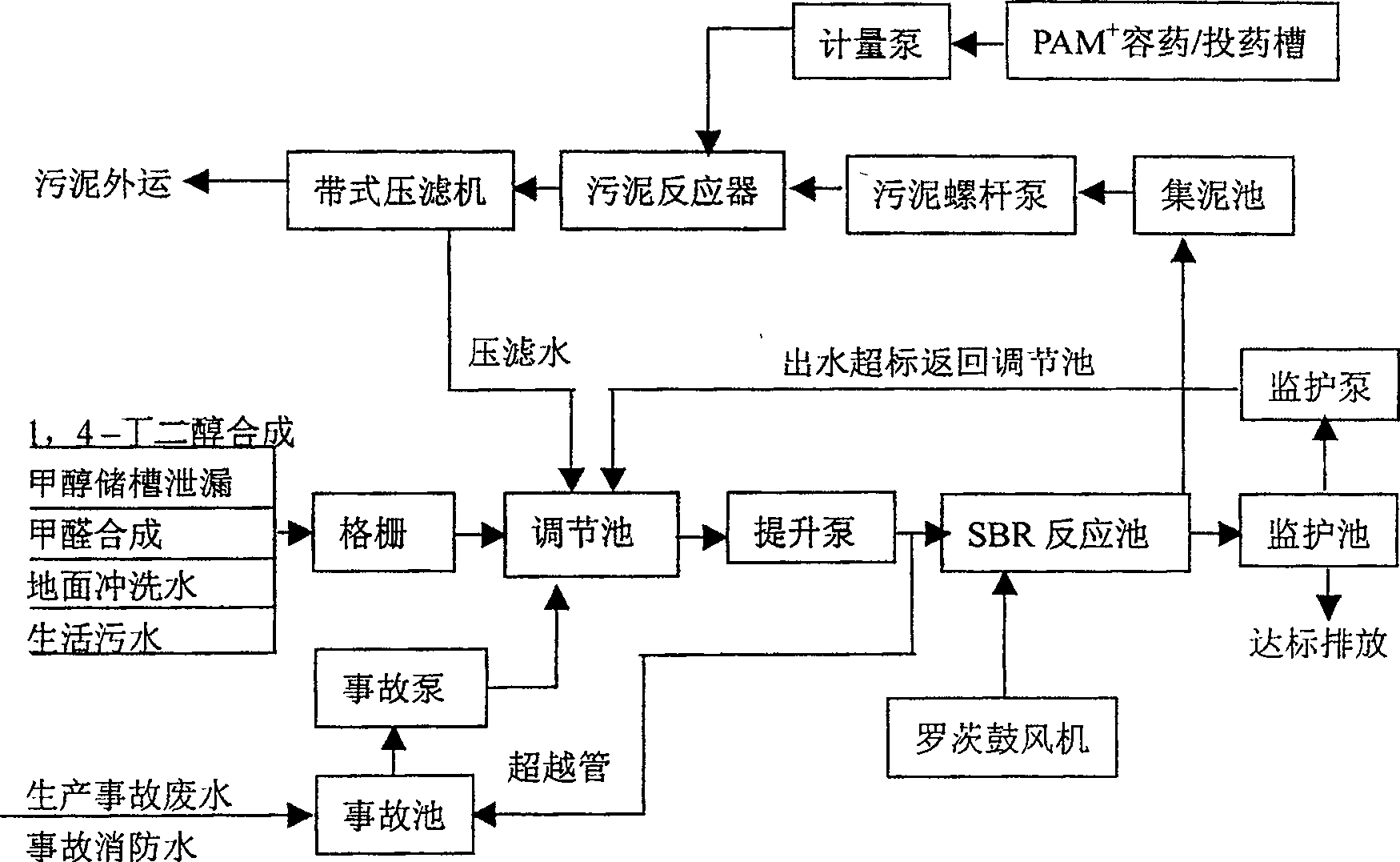

[0008] The waste water from 1,4-butanediol production first flows through the mechanical grille to remove large floating objects and larger particles, and then enters the regulating tank, where a submersible mixer is installed for continuous stirring to fully mix the raw water evenly. The waste water is sent to the SBR reactor through the lift pump for treatment, and a cycle is completed through aeration, sedimentation, decanting, and idle processes; in the aerobic aerobic stage, organic matter is degraded by aerobic microorganisms, and the DO concentration in this stage is controlled at 3- 4mg / L, the DO online monitor is interlocked with the frequency converter of the Roots blower to ensure the concentration of DO. The ORP online monitor is used to judge the redox capacity of the aerobic stage, that is, the processing capacity of the SBR reactor; During the idle period, the submersible mixer is automatically started to stir, and the anaerobic + anoxic reaction is performed, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com