Motor speed control circuit

A speed control, speed voltage technology, applied in the direction of DC motor speed/torque control, single-phase motor control, AC motor control, etc., to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]

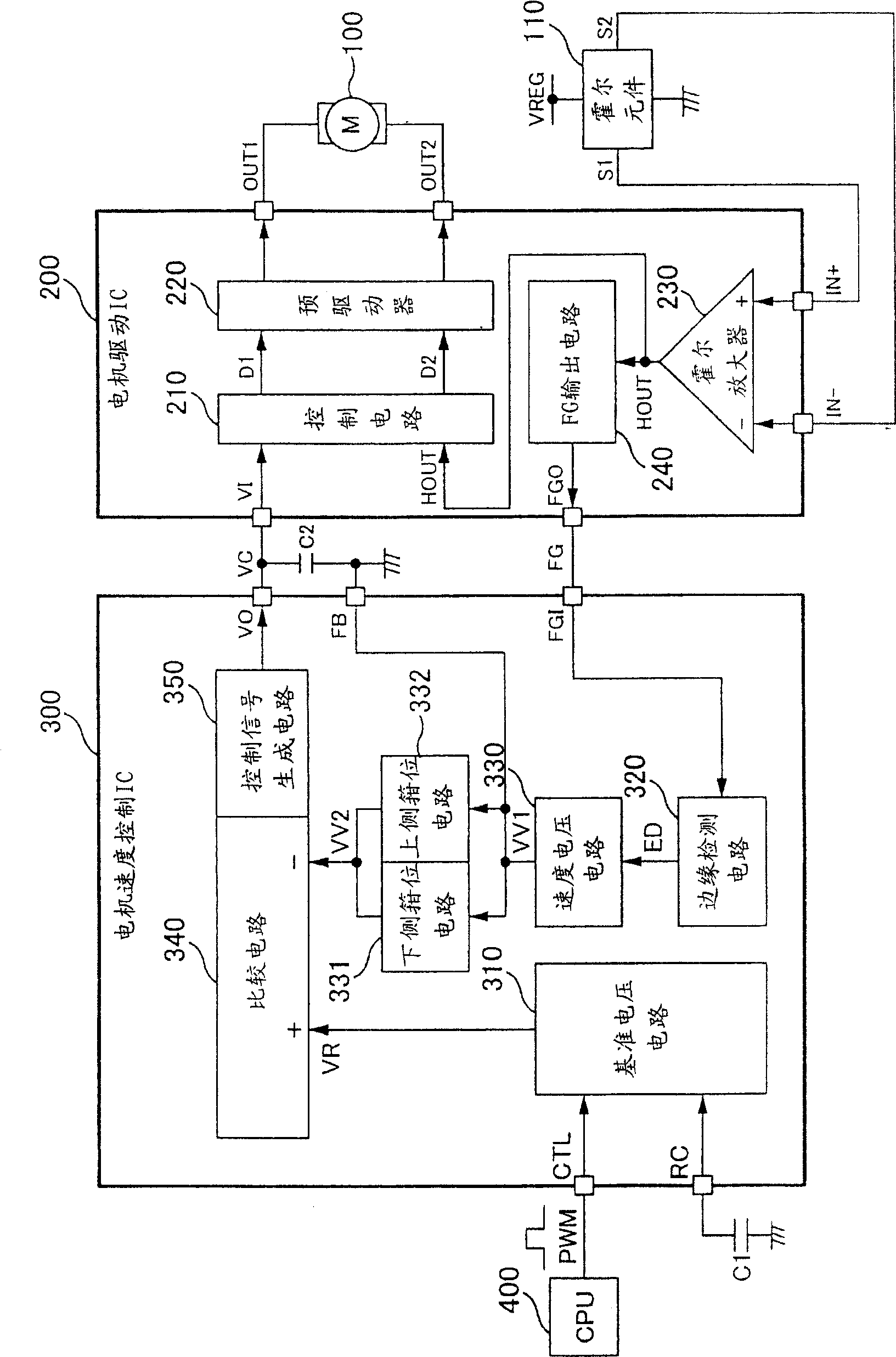

[0028] Appropriate reference Figure 2 to Figure 9 ,based on figure 1 A configuration example of the motor speed control system of the present invention will be described.

[0029] figure 1 The motor speed control system shown includes: a motor 100 to be controlled, a motor driver IC 200 ("first circuit" of the present invention), and a motor speed control IC 300 ("second circuit" of the present invention). That is, the "motor speed control circuit" of the present invention is a case of a two-chip structure in which the motor driver IC 200 and the motor speed control IC 300 are respectively integrated on one chip. In addition, the "motor speed control circuit" of the present invention may be a case where the motor driver IC 200 and the motor speed control IC 300 are integrated on one chip.

[0030] The motor 100 is a so-called single-phase motor having a single-phase drive coil, and a so-called Hall motor in which a Hall element 110 is fixed to a stator. In ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com