A control method of electronically controlled silicon oil fan clutch

A technology of clutch control and fan, which is applied in the control of coolant flow, machine/engine, engine cooling, etc. It can solve the problems of inability to realize fan multi-level speed regulation, poor cooling effect, loud noise, etc., and solve the problem of OFF state Insufficient cooling efficiency, low noise, and high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The embodiment of the present invention is illustrated by examples below. What this example uses is a six-cylinder heavy truck engine electronic controller. Burn domestic software in the controller. The implementation steps are as follows:

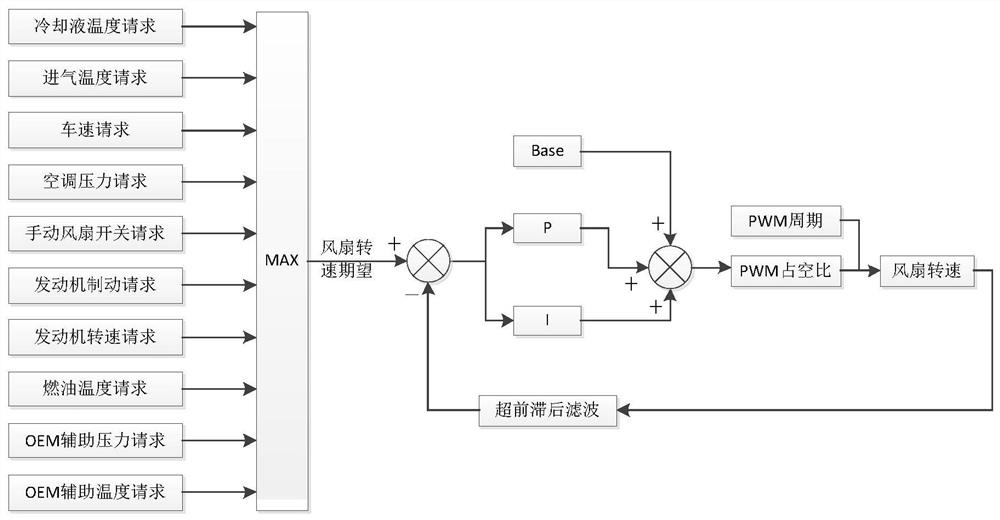

[0067] Step 1: Calculate the expected value of the fan speed under the current engine operating condition according to the influencing factors of the engine temperature: the influencing factors include coolant temperature, intake air temperature, vehicle speed, air-conditioning pressure, manual fan switch, engine braking, engine speed, and fuel temperature , OEM auxiliary pressure, OEM auxiliary temperature;

[0068] Step 1.1: Calculate the desired fan speed request percentage corresponding to each influencing factor, and select the largest desired fan speed request percentage as the desired fan speed percentage Rqst_Rt;

[0069] In this embodiment, the largest expected fan speed request percentage among the expected fan speed reque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com