Semiconductor optoelectronic component and its cutting method

A technology of photoelectric components and cutting methods, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, photovoltaic power generation, etc., can solve problems affecting the light extraction effect of light-emitting diode crystal grains, and achieve improved light extraction efficiency, good appearance, and improved crystal grains. The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

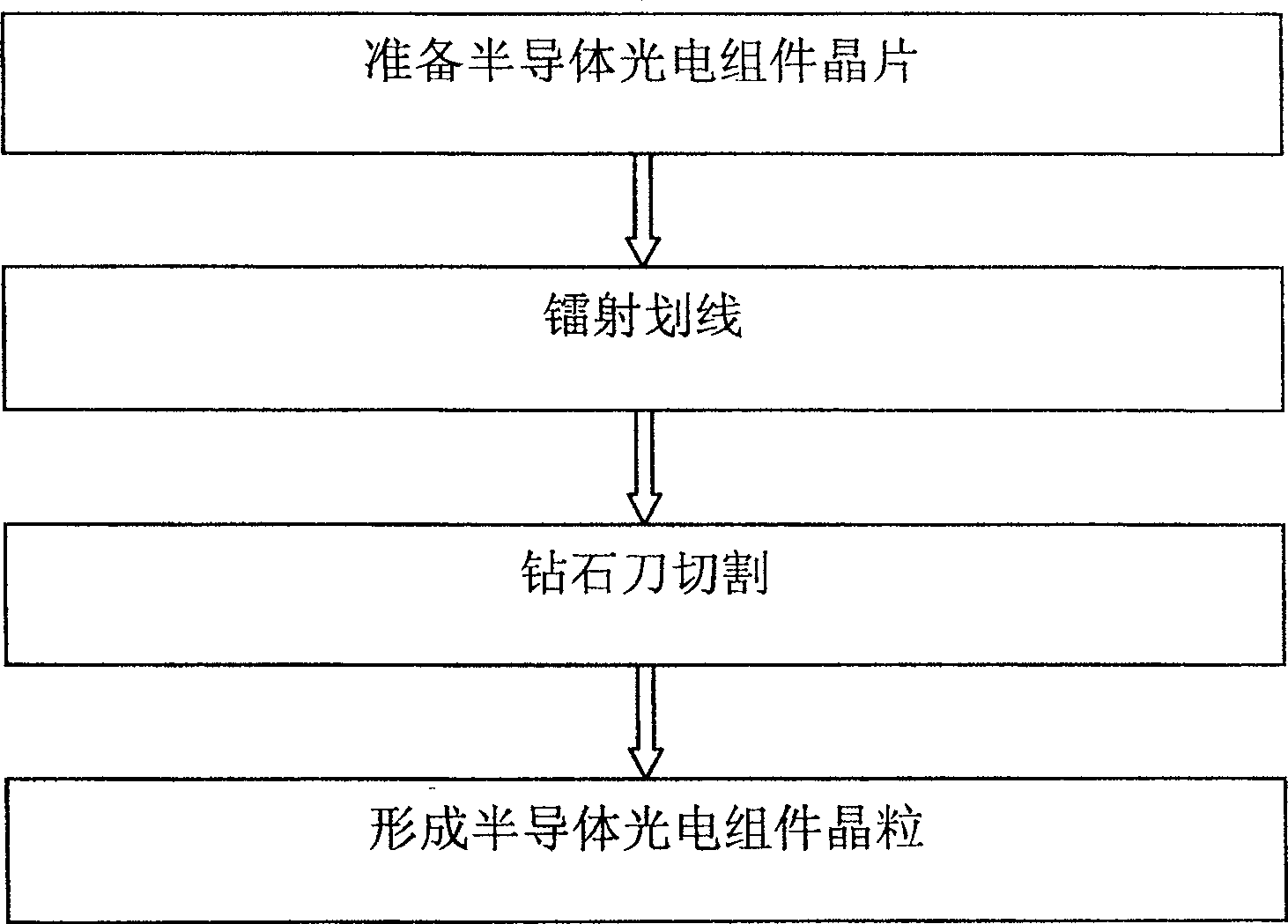

[0037] Please refer to figure 1 Shown, the cutting method of semiconductor optoelectronic component of the present invention is to comprise:

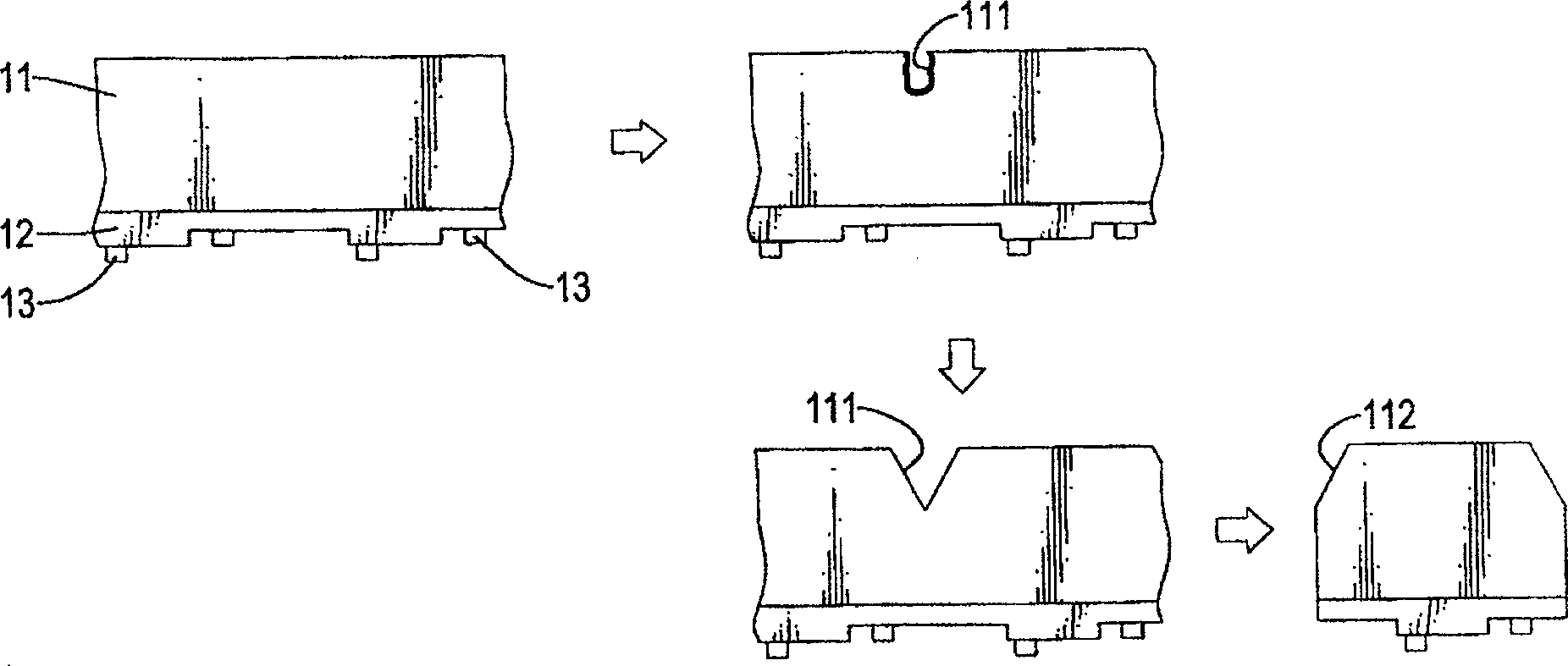

[0038] Prepare semiconductor optoelectronic component chips: please refer to figure 2 Shown, the semiconductor optoelectronic component chip is formed with an epitaxial silicon layer (12) on the substrate (11), and is provided with a metal electrode (13) on the epitaxial silicon layer (12), and this epitaxial silicon layer (12) material can be The semiconductor materials of III-V group compounds, such as materials such as GaN, GaS, GaP, InP, InGaAlN, InGaAlP, InGaAlAs and GaAlPAs; The epitaxial silicon layer (12) material can also be the semiconductor materials of II-VI group compounds, such as ZnO, Materials such as ZnSe, ZnS and ZnTe; the material of the epitaxial silicon layer (12) can also be semiconductor materials of group IV elements, such as Si and Ge and other materials.

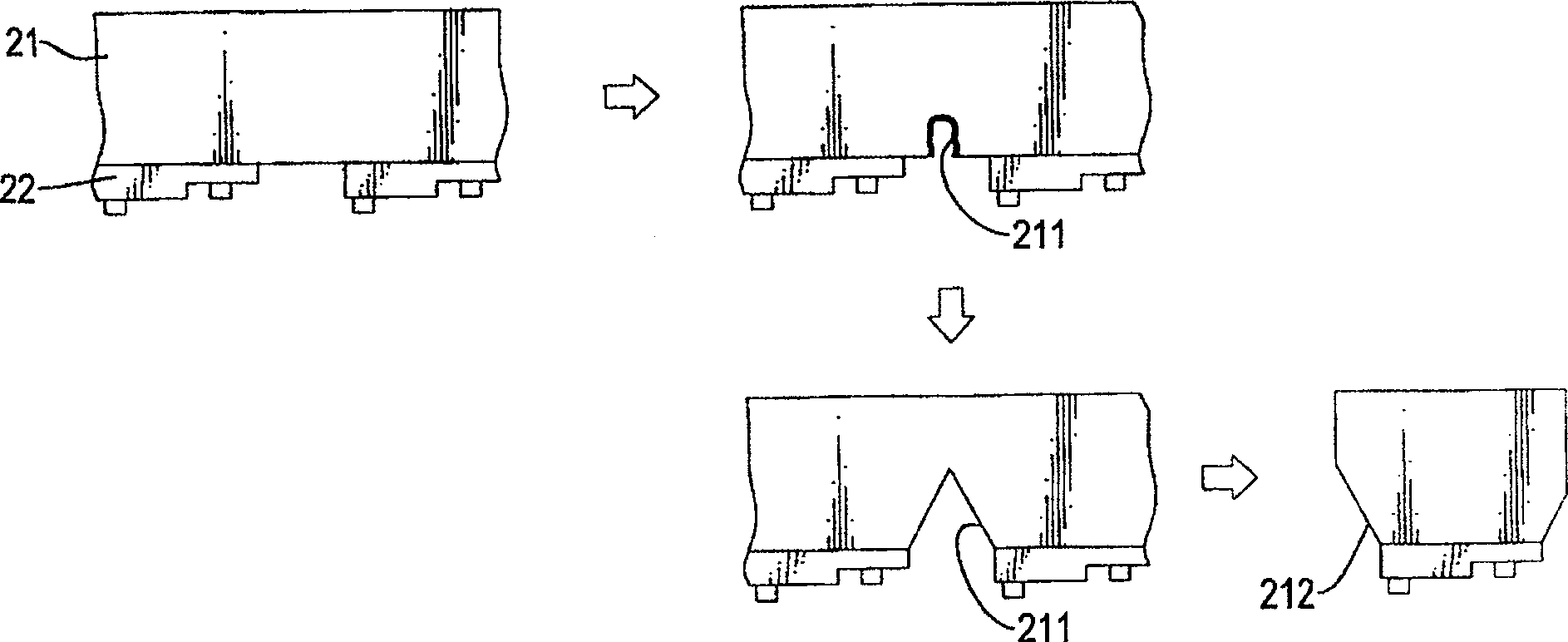

[0039] Laser scribing: Use laser to draw a guide gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com