Highway dredging mud ceramicite cement concrete and method for preparing the same

A technology of cement concrete and concrete, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of poor performance and high consumption, and achieve the effects of reducing production costs, driving comfort, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

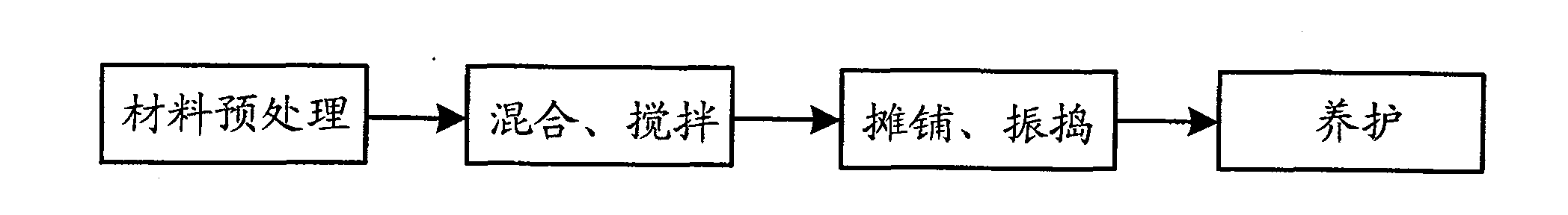

Method used

Image

Examples

Embodiment 1

[0034] Embodiment one: each raw material is calculated by weight proportion, gets dredging mud ceramsite 167 parts, gravel 198 parts, cement 189 parts, sand 378 parts, water 68 parts, fly ash replaces cement percentage and is 10%, excess substitution coefficient is 1.6, and the powdered FDN-2 naphthalene series high-efficiency water reducer accounts for 0.8% of the total amount of cement and fly ash.

[0035] Among them, the dredging mud ceramsite satisfies the following properties: cylinder compressive strength > 4MPa, water absorption 500, particle size 5-20mm, particle shape coefficient ≤ 1.2, softening coefficient ≥ 0.85, firmness (according to Mass loss) < 5%, boiling mass loss ≤ 4%, ignition loss ≤ 4%, sulfide and sulfate content (calculated as sulfur trioxide) < 0.5%, mud content < 1.0%, organic matter content is not deep in standard colors. .

[0036] First of all, the raw materials are pretreated, mainly referring to the pre-wet treatment of dredged mud ceramsite. ...

Embodiment 2

[0041] Embodiment two: each raw material is calculated by weight proportion, gets dredging mud ceramsite 167 parts, gravel 197 parts, cement 190 parts, sand 369 parts, water 77 parts, fly ash replaces cement percentage and is 10%, excess substitution coefficient is 1.6, and the powdered FDN-2 naphthalene series high-efficiency water reducer accounts for 0.8% of the total amount of cement and fly ash.

[0042] Preparation was carried out according to the steps of Example 1, and various performance indexes of the prepared concrete were tested.

Embodiment 3

[0043]Embodiment three: each raw material is calculated by weight proportion, gets dredging mud ceramsite 163 parts, crushed stone 193 parts, cement 192 parts, sand 369 parts, water 82 parts, fly ash replaces cement percentage and is 10%, excess substitution coefficient is 1.6, and the powdered FDN-2 naphthalene series high-efficiency water reducer accounts for 0.8% of the total amount of cement and fly ash.

[0044] Preparation was carried out according to the steps of Example 1, and various performance indexes of the prepared concrete were tested.

[0045] The performance index parameters of the dredged mud ceramsite concrete prepared in the above three embodiments are shown in the table below.

[0046] Performance

[0047] It can be seen from the performance indicators of the concrete in the above table that the dredged mud ceramsite cement concrete has excellent performance, fully meets the road performance requirements, realizes waste utilization, saves natural...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cylinder compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com