Dredging mud ceramic granule asphalt concrete for road and preparation method thereof

A technology of asphalt concrete and clay ceramsite, which is applied in the direction of roads, roads, and on-site cohesive pavements. It can solve problems such as poor performance and high consumption, and achieve the effects of reducing production costs, saving resources, and reducing consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

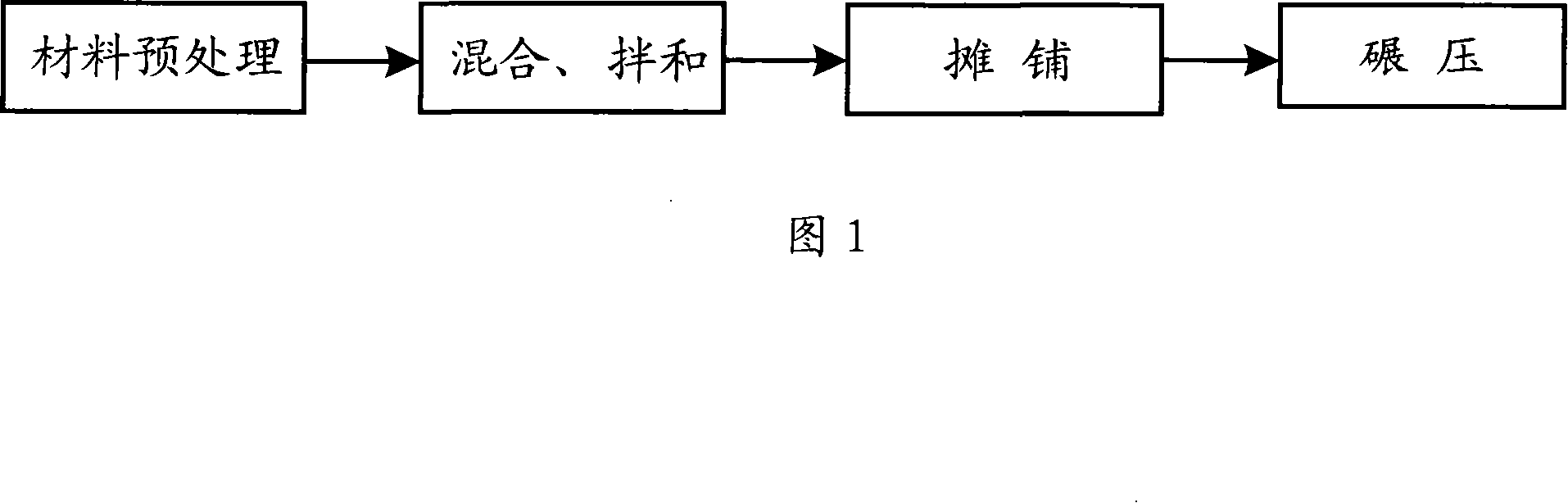

Image

Examples

Embodiment 1

[0031] Embodiment 1: Each raw material is calculated by weight ratio, 52 parts of asphalt AH-90, 522 parts of gravel, 218 parts of dredging mud ceramsite, 155 parts of sand, and 53 parts of limestone slag.

[0032] Among them, the dredging mud ceramsite satisfies the following properties: cylinder compressive strength > 6MPa, water absorption 700, particle size 5-16mm, particle shape coefficient ≤ 1.15, softening coefficient ≥ 0.85, firmness (according to Mass loss) < 5%, boiling mass loss ≤ 4%, ignition loss ≤ 4%, sulfide and sulfate content (calculated as sulfur trioxide) < 0.5%, mud content < 1.0%, organic matter content is not deep In the standard color, Los Angeles wear loss <28%, polishing value (BPN) <55, adhesion to asphalt ≥3, dredged mud ceramsite surface texture is coarse, and tightly combined with asphalt.

[0033] First, pretreatment of raw materials mainly refers to the preheating treatment of dredged mud ceramsite. The preheating temperature is the same as that...

Embodiment 2

[0037] Embodiment two: each raw material is calculated by weight ratio, gets 54 parts of petroleum pitch AH-90, 511 parts of crushed stones,

[0038] There are 254 parts of dredging mud ceramsite, 126 parts of sand, 47 parts of limestone slag, and 8 parts of cement.

[0039] The preparation of ceramsite asphalt concrete was carried out according to the steps of Example 1.

Embodiment 3

[0040] Embodiment three: each raw material is calculated by weight ratio, gets 58 parts of petroleum pitch AH-90, 456 parts of crushed stones,

[0041] 268 parts of dredging mud ceramsite, 160 parts of sand, 58 parts of limestone slag.

[0042] The preparation of ceramsite asphalt concrete was carried out according to the steps of Example 1.

[0043] The performance index parameters of the dredged mud ceramsite concrete prepared in the above three embodiments are shown in the table below.

[0044] Performance

[0045] It can be seen from the various performance indicators of the asphalt concrete in the above table that the dredged mud ceramsite asphalt concrete has excellent performance, fully meets the road performance requirements, realizes waste utilization, saves natural resources, is green and environmentally friendly, and can bring great benefits. economic and social benefits.

PUM

| Property | Measurement | Unit |

|---|---|---|

| cylinder compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com