LED structure

A technology of light-emitting diodes and covering layers, applied in the direction of electrical components, electrical solid devices, circuits, etc., to achieve the effects of high brightness, simple manufacturing process, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

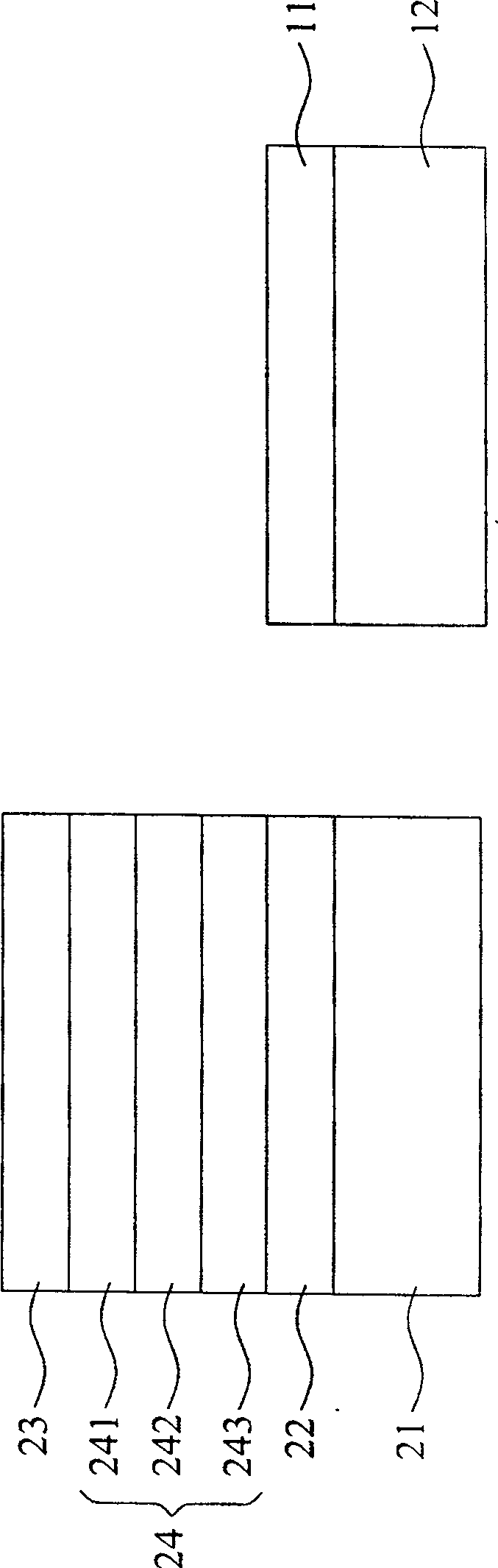

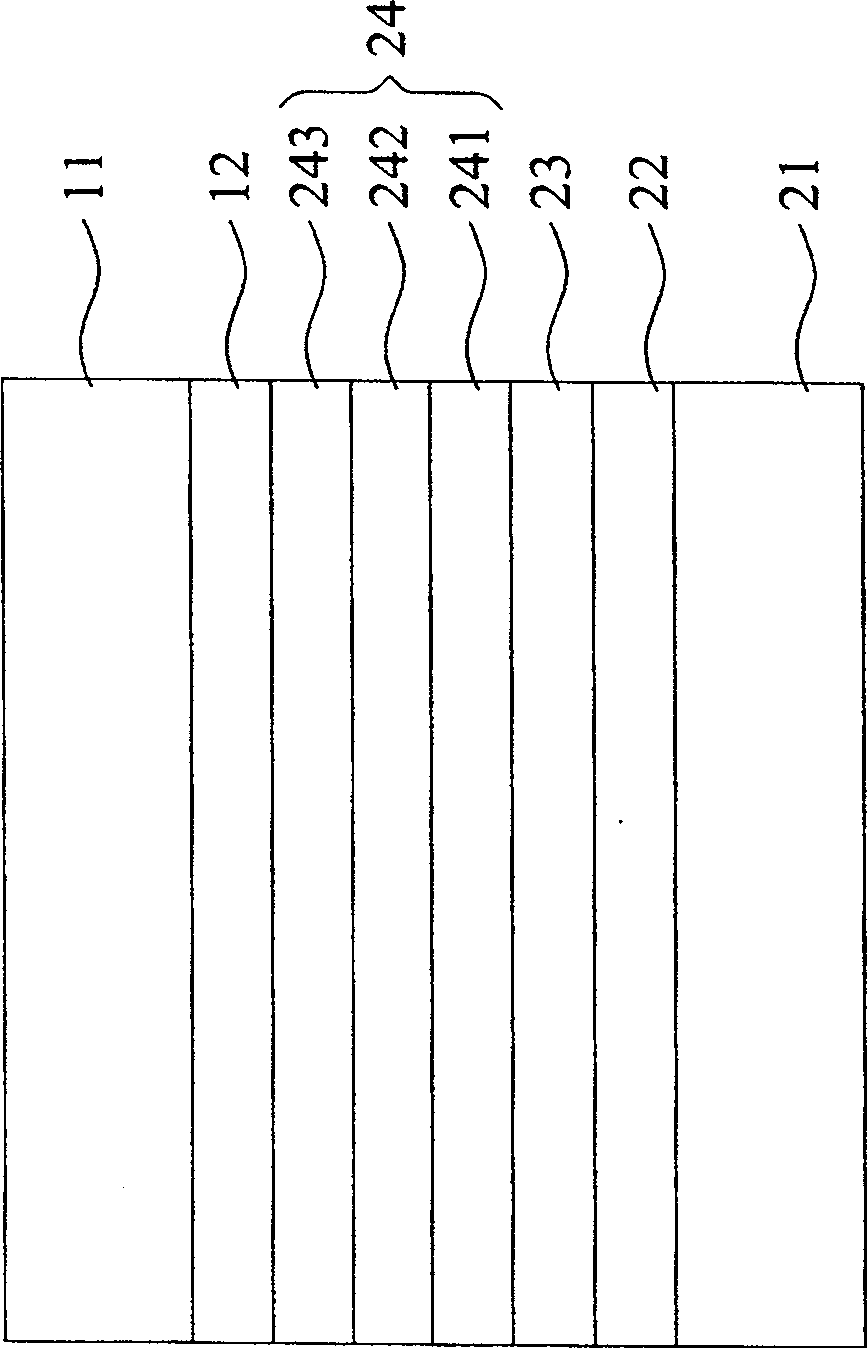

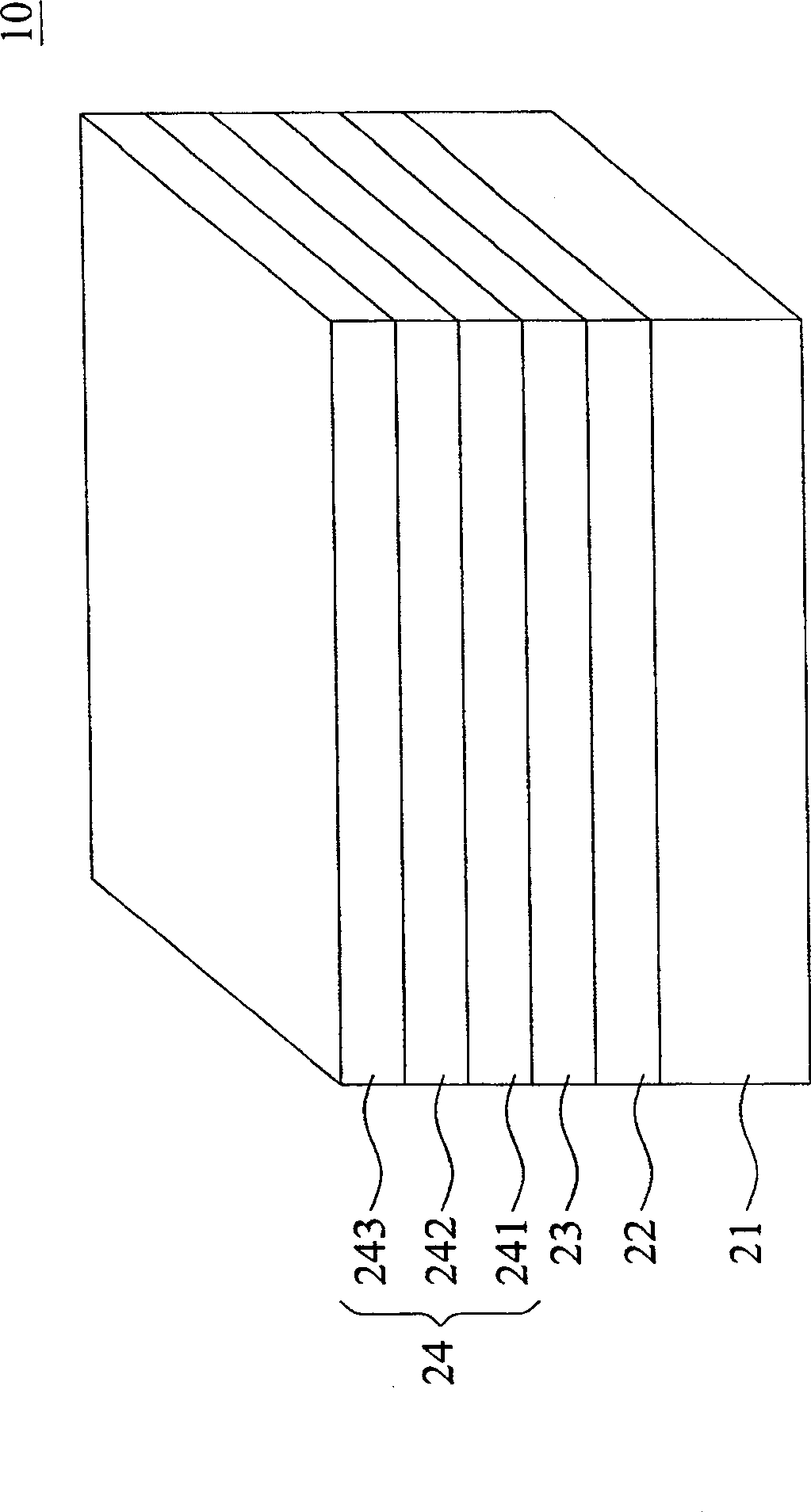

[0075] see Figure 1A , Figure 1B , Figure 1C as shown, Figure 1A It is a schematic diagram of an embodiment in which the first substrate 21 and the light-emitting diode structure 10 of the prior process have not been combined in the prior art, Figure 1B It is a schematic diagram of an embodiment after the first substrate 21 is combined with the light-emitting diode structure 10 of the previous process, Figure 1C will be Figure 1B The perspective view of the embodiment after the temporary substrate 11 and the etching stop layer 12 are removed.

[0076] Generally, the manufacture of the LED structure is to form the LED structure 10 of the pre-process that has not been divided into units and has not yet completed other insulating layers and conductive plates on a wafer in a semiconductor manufacturing process. However, when the actual light-emitting diode structure is applied, because the wafer is too thick and opaque, it cannot be applied and must be removed. Therefor...

no. 2 example

[0097] see Figure 7 to Figure 9 As shown in B, this embodiment is a light emitting diode structure 30, which includes: a first substrate 21, an adhesive layer 22, at least two first ohmic connection layers 23', at least two polycrystalline layers 24, a second The insulating layer 31 , at least two fifth conductive plates 32 and at least two sixth conductive plates 33 .

[0098] The light-emitting diode structure 30 of this example can be used similar to the first embodiment Figure 1A to Figure 1C process, the first substrate 21 coated with the adhesive layer 22 is combined with the pre-process LEDs 28 formed on the wafer. Then, the temporary substrate 11 and the etch stop layer 12 are removed by etching to obtain the light emitting diode structure 30 that has not been divided into units.

[0099] The above-mentioned first substrate 21 has a first surface 211 and a second surface 212 , and the first substrate 21 is mainly used to support the entire LED structure 30 . The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com