Screw pile, thread pile piling equipment and piling method

A threaded pile and screw pile technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of insufficient self-weight, low bearing capacity, and insufficient pressure of equipment, and achieve power output, power saving, time saving, and safety performance Improvement, the effect of increasing the drilling depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

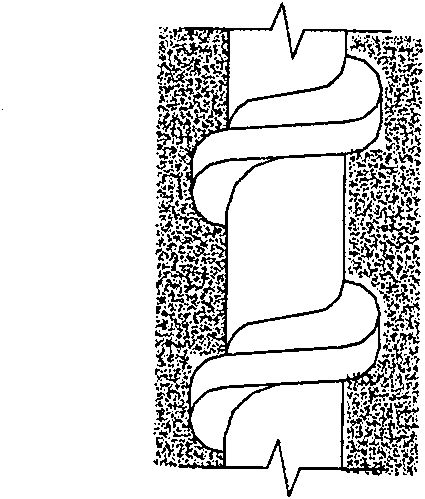

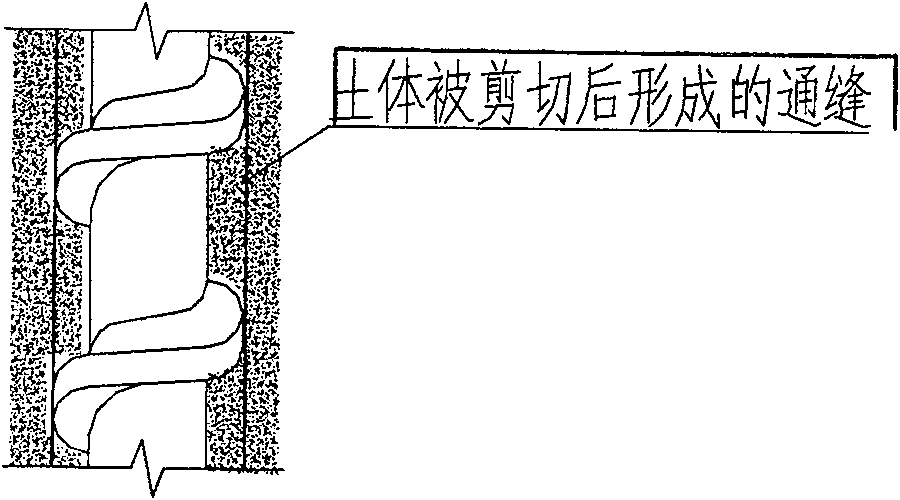

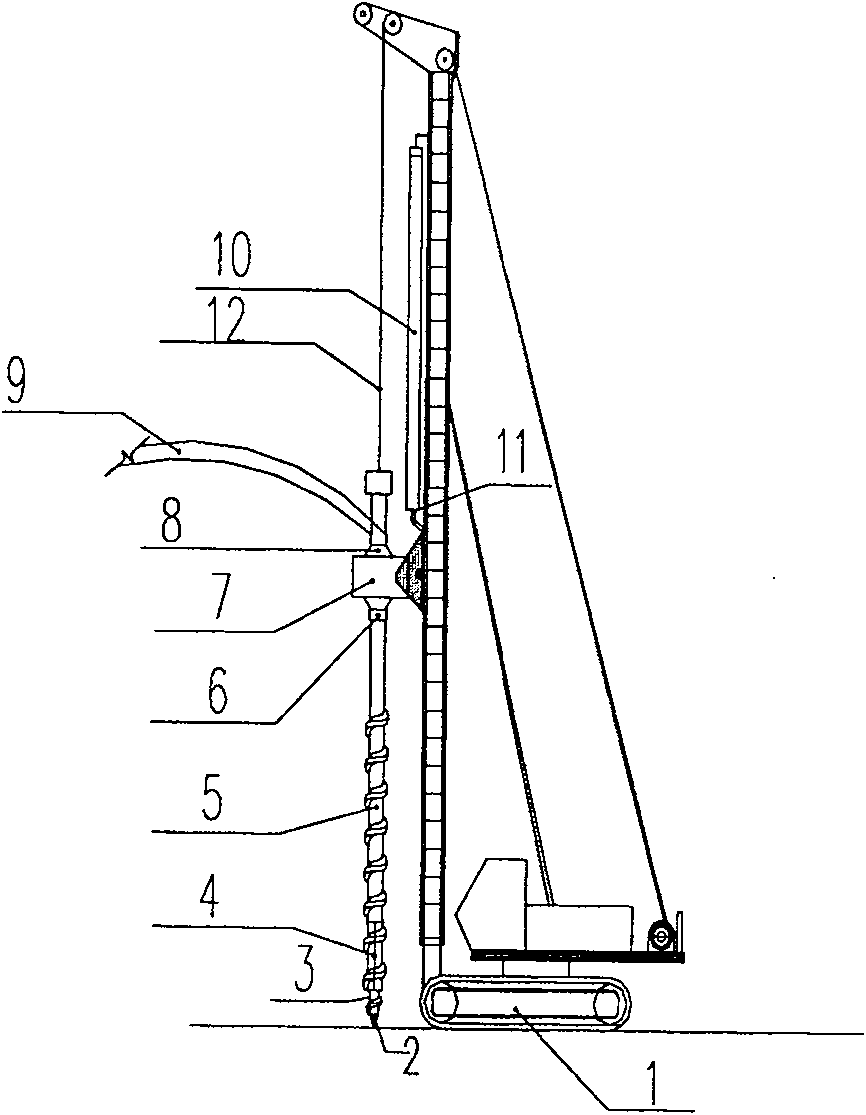

[0033] Structural drawings further describe the present invention.

[0034] Such as image 3 , Figure 4 As shown, the screw pile and threaded pile forming equipment of the present invention are mainly composed of the following components: a body, a telescopic oil cylinder, a motor, an automatic control device, and a delivery pipeline. The body mainly includes a frame 1, a power head 7 and a drill rod 6 , the power head 7 is installed on the stand of the frame 1, the motor 16 is installed on the body base 1, the motor 16 is connected with the power head 7 through the telescopic oil cylinder 10, the clamp on the drill pipe 6 is connected with the movable clamp of the power head 7 8 are connected, the power head and the inner drill pipe 6-1 are connected with a reciprocating helical bayonet 14, the concrete delivery pipeline 9 is connected with the inner drill pipe 6-1, and the lower end of the telescopic oil cylinder 10 is provided with a feed speed sensor 11, The up and down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com