Coating and anti-corrosion method for steel products

A technology for anti-corrosion and steel materials, which is applied in the field of steel pipe piles, can solve the problems of insufficient matching of anti-corrosion belts, gaps between anti-corrosion belts and steel materials, and poor adhesion, so as to prevent the reproduction of organisms and achieve good anti-corrosion performance , good compactness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

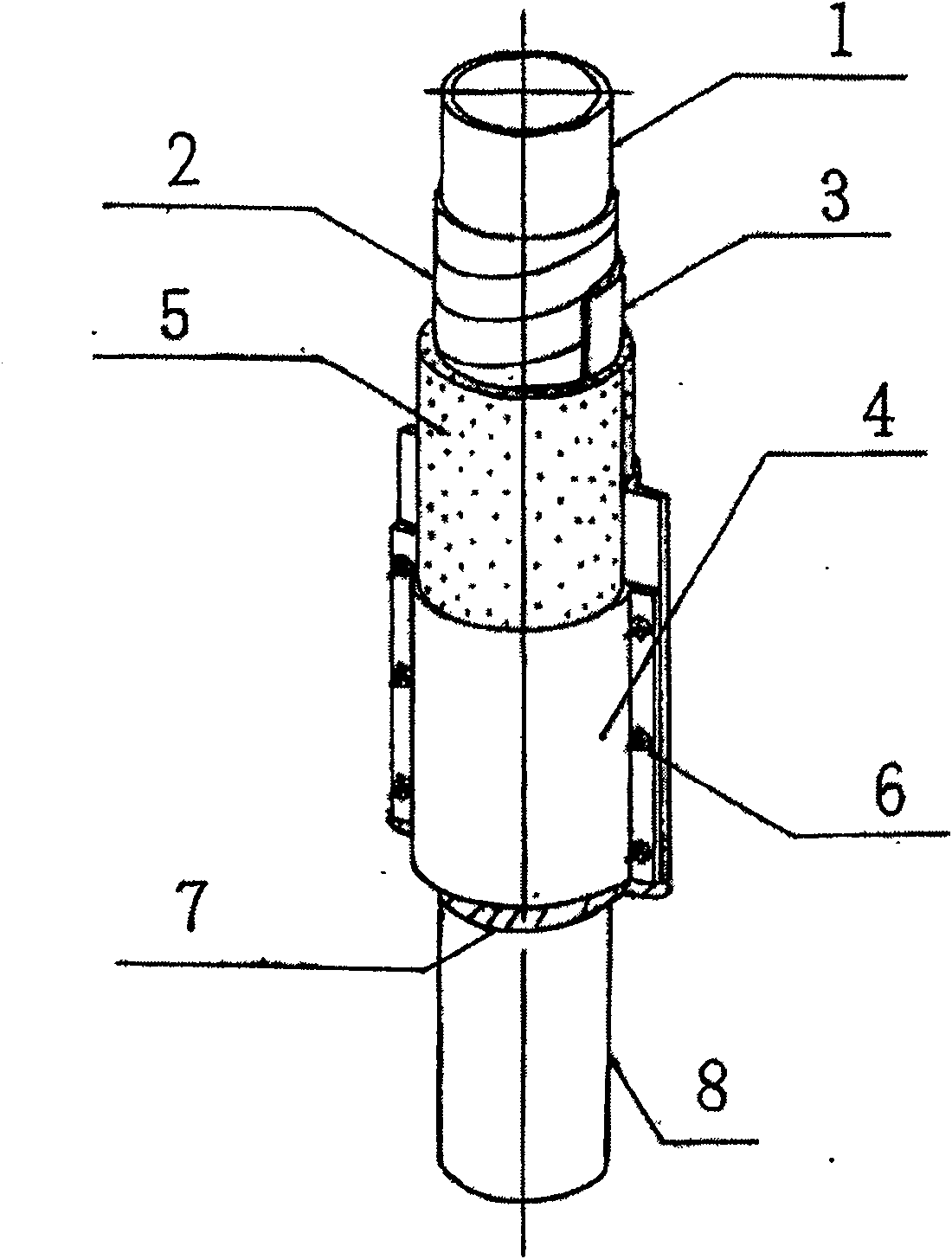

[0028] This embodiment takes steel pipe piles or steel sheet piles 8 steel materials built in oceans and rivers as an example: figure 1 As shown, a pasty mineral lipid anti-corrosion material 1 is coated on its surface, and a strip-shaped mineral lipid anti-corrosion tape 2 is wound on it, and then the protective cover 4 and the inner surface of the protective cover are further used. The buffer material 5 that foam plastic material or rubber constitutes wraps.

[0029] see figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 8 As shown: the upper and lower ends of the protective cover 4 are filled with water-curable resin 7 to seal the mineral lipid anti-corrosion material 1 . There are fixed flanges on both sides of the protective cover 4. At the joint position of the flanges, a plate 3 made of plastic or fiber reinforced plastic is added to connect the belt-shaped mineral grease anti-corrosion belt 2 and the buffer. The plate 3 made of plastic or fiber-re...

Embodiment 2

[0045] Determination of anti-corrosion effect:

[0046] Place the 4 steel pipes in the splash zone at the positions of +3.55m, +2.95m, +1.70m, +1.10m, and at the same time use the method of Example 1 to protect the above 4 steels, and take them back after 1168 days. Corrosion weight loss to calculate corrosion rate.

[0047] The unprotected steel was used as a control, which was also placed in the above four different locations, and retrieved after 1168 days, and the corrosion rate was calculated from the weight loss of the test piece.

[0048] Calculation method of anti-corrosion effect:

[0049] Corrosion protection rate (%)=[(corrosion rate of control)-(corrosion rate of test)]×100 / (corrosion rate of control)

[0050] The results are shown in the table below

[0051] tide level

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com