Printing adhesive liner cloth and its making process

A fusible interlining and printing technology, applied in the direction of transfer printing, printing, printing technology, etc., can solve the problems of not satisfying consumers, achieve strong sensory effects, three-dimensional hand feeling, uniform force, and avoid falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

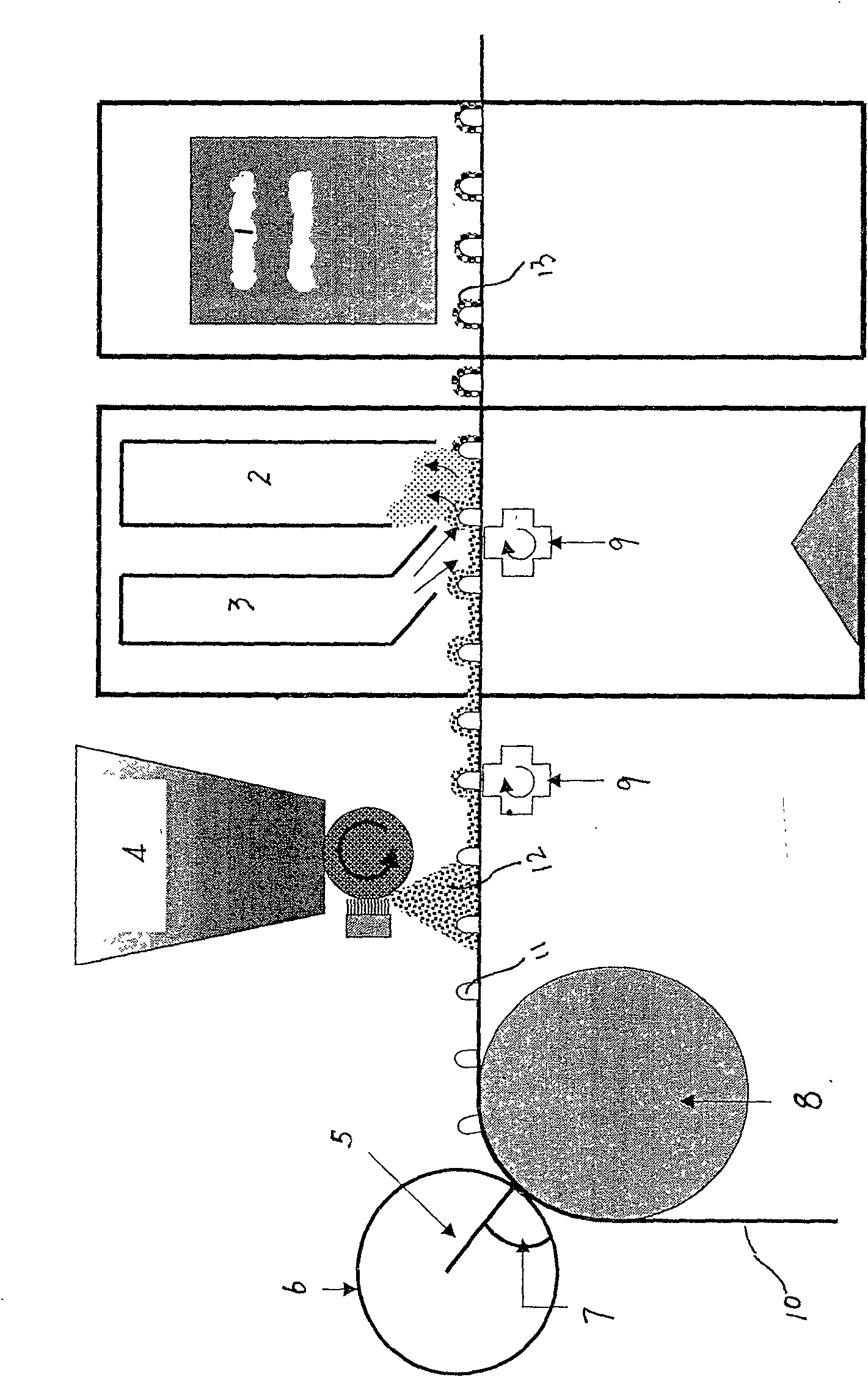

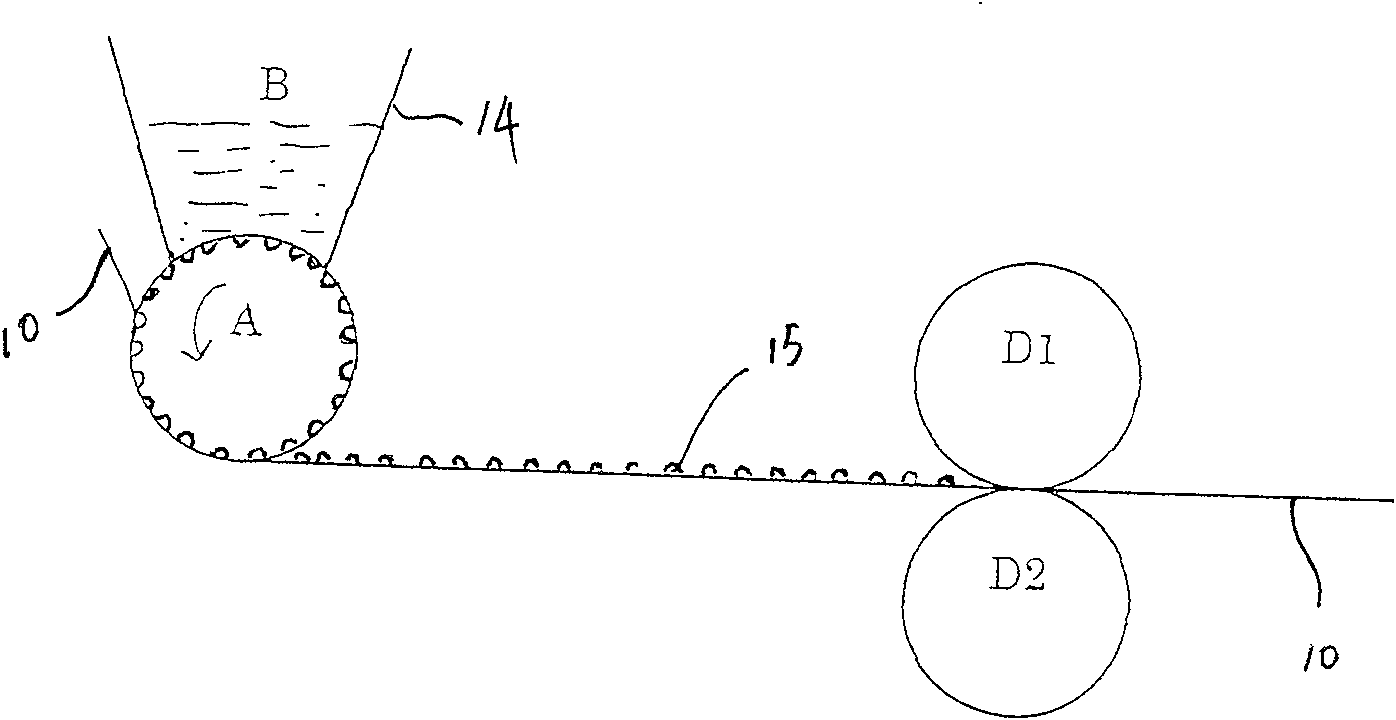

Method used

Image

Examples

Embodiment 1

[0034] 30D / 24F long fiber polyester twisted yarn, mesh weight 34g / m 2 plain fabric bottom.

[0035] Scouring: Add the required amount of scouring liquid made of water and additives into the liquid tank of the refining machine. The ingredients of the additives are 0.1 g / L of metal ion chelating agent, 0.1 g / L of softener in the bath, surfactant 0.1 g / L, 3 g / L sodium hydroxide, 0.5 g / L desizing agent, and the rest is water. After heating up to 75°C, put the fabric into the liquid tank, and make the water and the fabric circulate in the liquid tank together. Then heat up to the scouring temperature of 95°C, after 5 minutes of scouring, drain the refining solution, add cold water to wash and take it out;

[0036]Finishing: Add a finishing solution made of water and additives into the liquid tank of the finishing machine. The components of the additives are 2 g / L softener, 0.5 g / L antistatic agent, 0.2 g / L penetrant, yellowing 1 g / liter of preventive agent is water, and the above...

Embodiment 2

[0041] 50D / 48F long fiber polyester base fabric

[0042] Scouring: Add the required amount of scouring liquid made of water and additives into the liquid tank of the refining machine. The ingredients of the additives are 0.3 g / L of metal ion chelating agent, 0.3 g / L of softener in the bath, surfactant 0.3 g / L, 4 g / L sodium hydroxide, 0.5 g / L desizing agent, and the rest is water. After the temperature rises to 85°C, put the fabric into the liquid tank, and make the water and the fabric circulate in the liquid tank together. Then heat up to scouring temperature of 100°C, after scouring for 20 minutes, drain the refining solution, add cold water to wash and take it out;

[0043] Finishing: Add the finishing liquid made of water and additives into the liquid tank of the finishing machine. The ingredients of the additives are 4 g / L softener, 0.3 g / L antistatic agent, and 0.5 g / L anti-yellowing agent. The rest is water, after the above-mentioned refined fabric is pad-rolled with t...

Embodiment 3

[0048] 50D / 48F long fiber polyester base fabric

[0049] Scouring: Add the required amount of scouring liquid made of water and additives into the liquid tank of the refining machine. The ingredients of the additives are 0.3 g / L of metal ion chelating agent, 0.3 g / L of softener in the bath, surfactant 0.3 g / L, 4 g / L sodium hydroxide, 0.5 g / L desizing agent, and the rest is water. After the temperature rises to 85°C, put the fabric into the liquid tank, and make the water and the fabric circulate in the liquid tank together. Then heat up to scouring temperature of 100°C, after scouring for 20 minutes, drain the refining solution, add cold water to wash and take it out;

[0050] Finishing: Add the finishing liquid made of water and additives into the liquid tank of the finishing machine. The ingredients of the additives are 5 g / L softener, 0.5 g / L antistatic agent, and 0.5 g / L anti-yellowing agent. The remaining is water, after the above-mentioned refined fabric is pad-rolled w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com