Large power long range permanent magnetism synchronous linear motor servo drive apparatus

A permanent magnet synchronous linear and servo drive technology, which is applied to the reduction gear of AC motors, motor generators/starters, non-electric variable control, etc., can solve problems such as affecting system performance, increasing development costs, and increasing system costs. , to achieve the effect of improving security performance, solving startup problems, and meeting upgrade requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described below in conjunction with the accompanying drawings and specific embodiments.

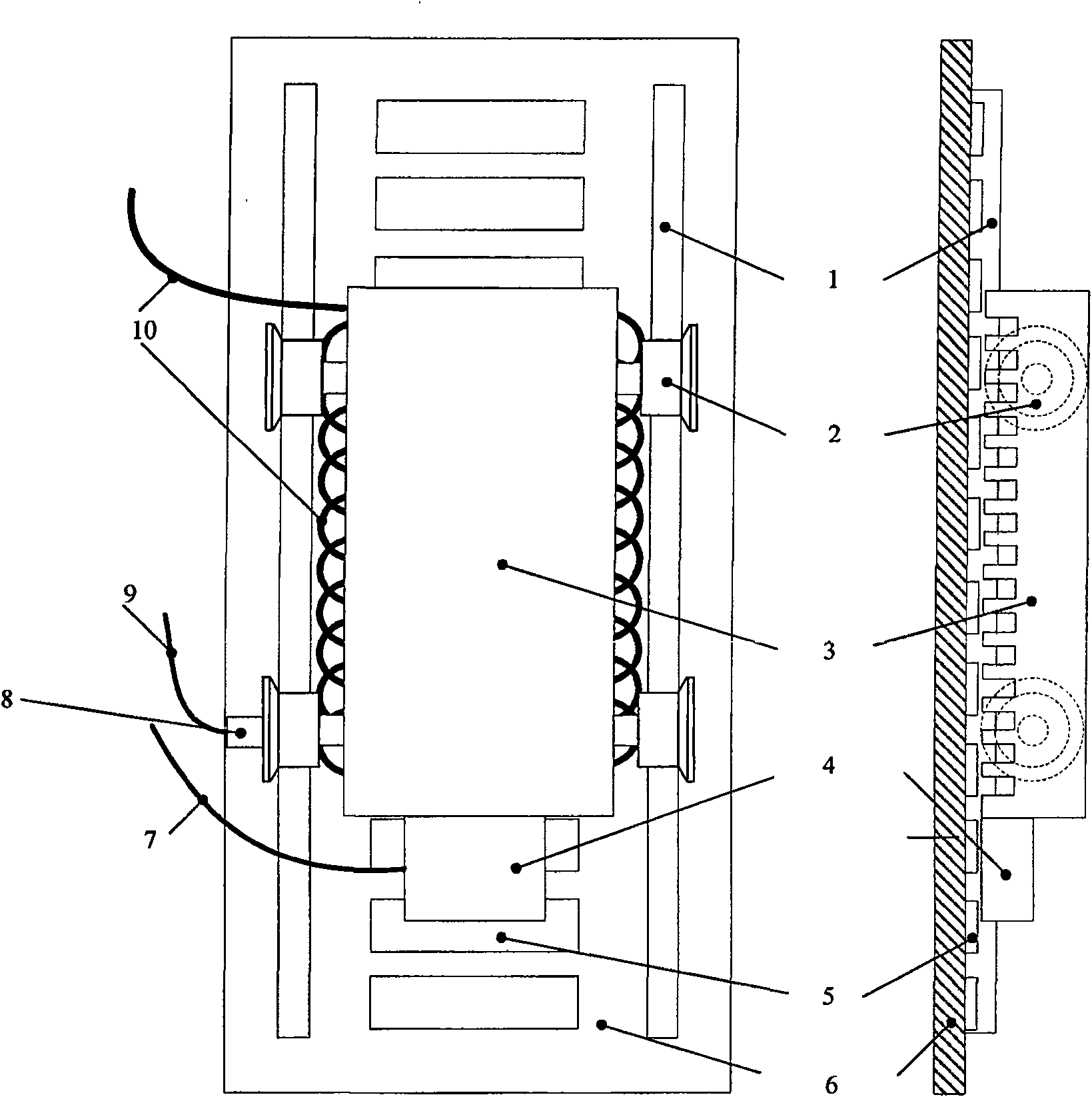

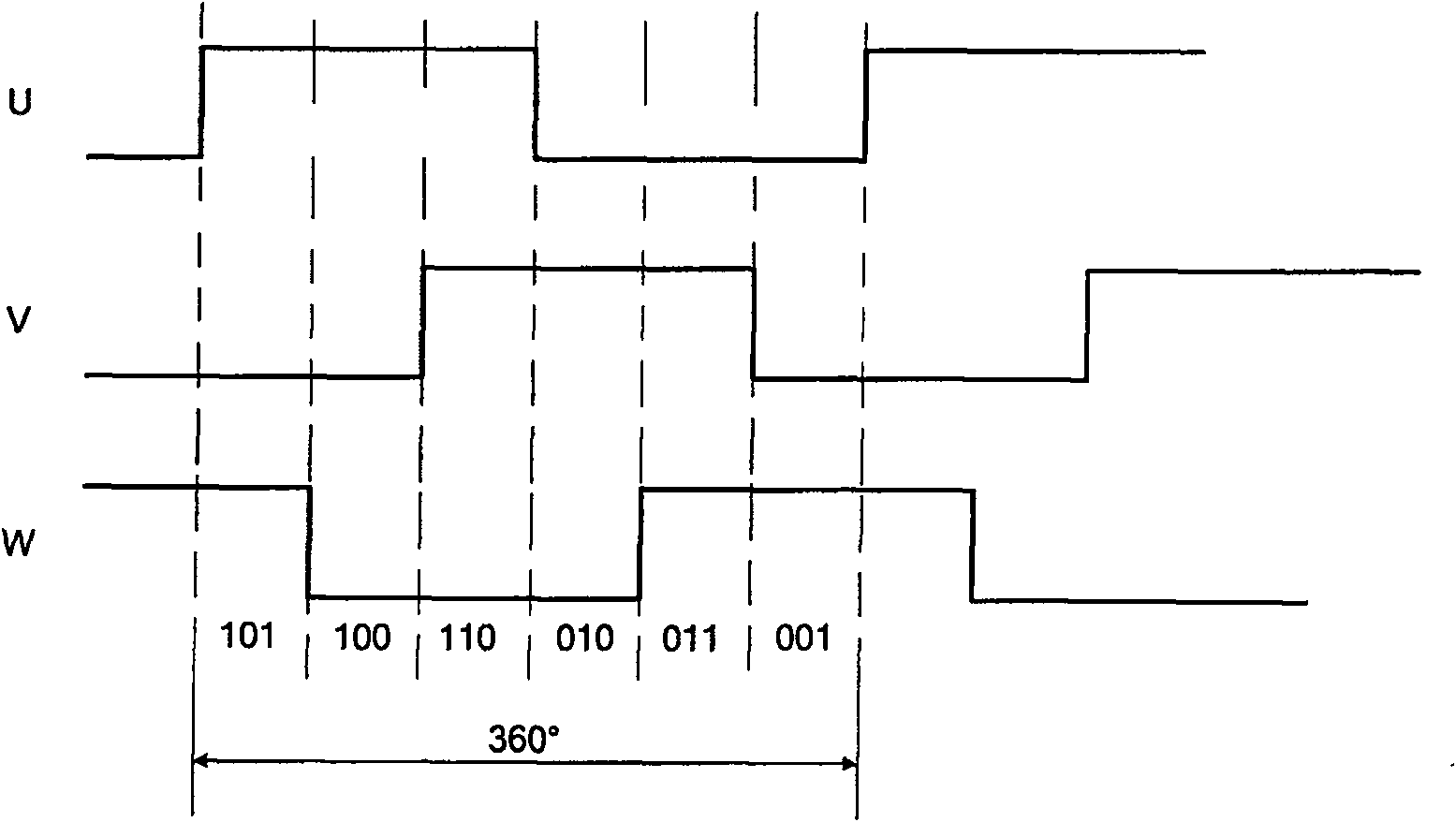

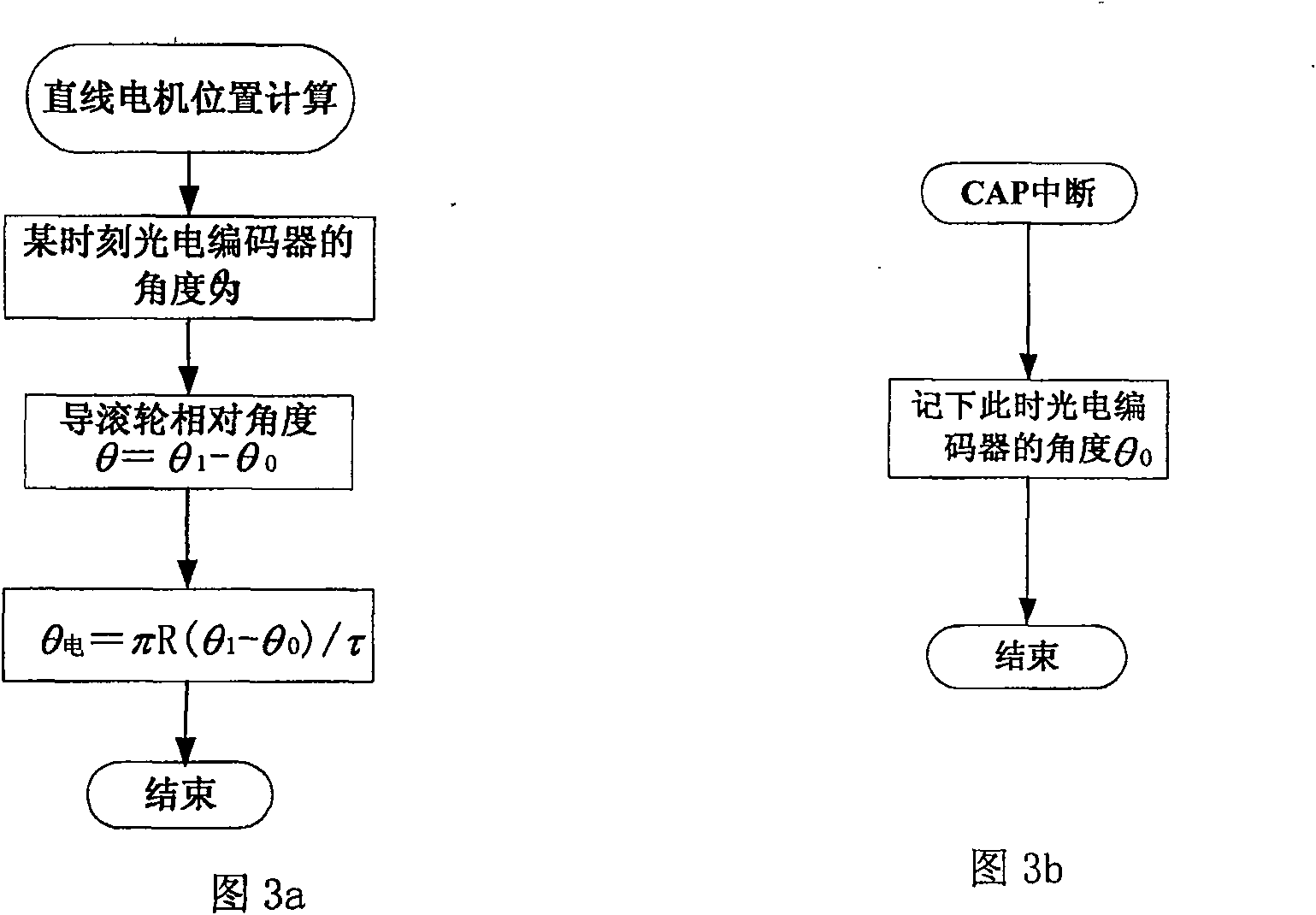

[0019] like figure 1 As shown, in this embodiment, the incremental rotary photoelectric encoder 8 is installed on the guide roller 2, the guide roller 2 and the motor mover 3 are fixed together, and move back and forth on the guide rail 1, and the linear motor stator permanent magnet 5 is fixed on the bottom plate 6. The A, A, B, B, Z, Z signals generated by the incremental photoelectric encoder 8 can be used to measure the rotation angle and rotation speed of the guide roller 2, and the rotation speed and rotation angle of the guide roller 2 are proportional to the speed and displacement of the motor mover 3. Proportional, so the speed and displacement of the motor mover 3 can be further obtained. A position sensor 4 including three Hall position sensors Hall1, Hall2 and Hall3 is installed at the end of the motor mover 3 . The armature power line 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com