Method for graft modification of polyethersulfone

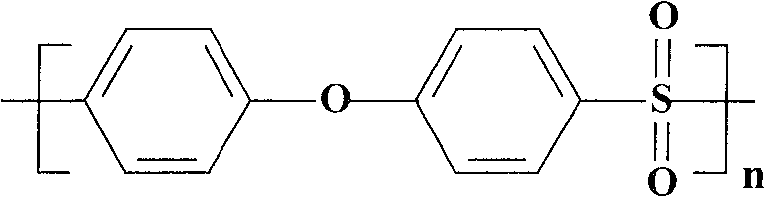

A technology of graft modification and polyethersulfone, which is applied in the field of polyethersulfone graft modification, can solve the problems of affecting the actual use effect of the membrane and the decrease of the working efficiency of the membrane, so as to increase the service life, improve the hydrophilicity, and Hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

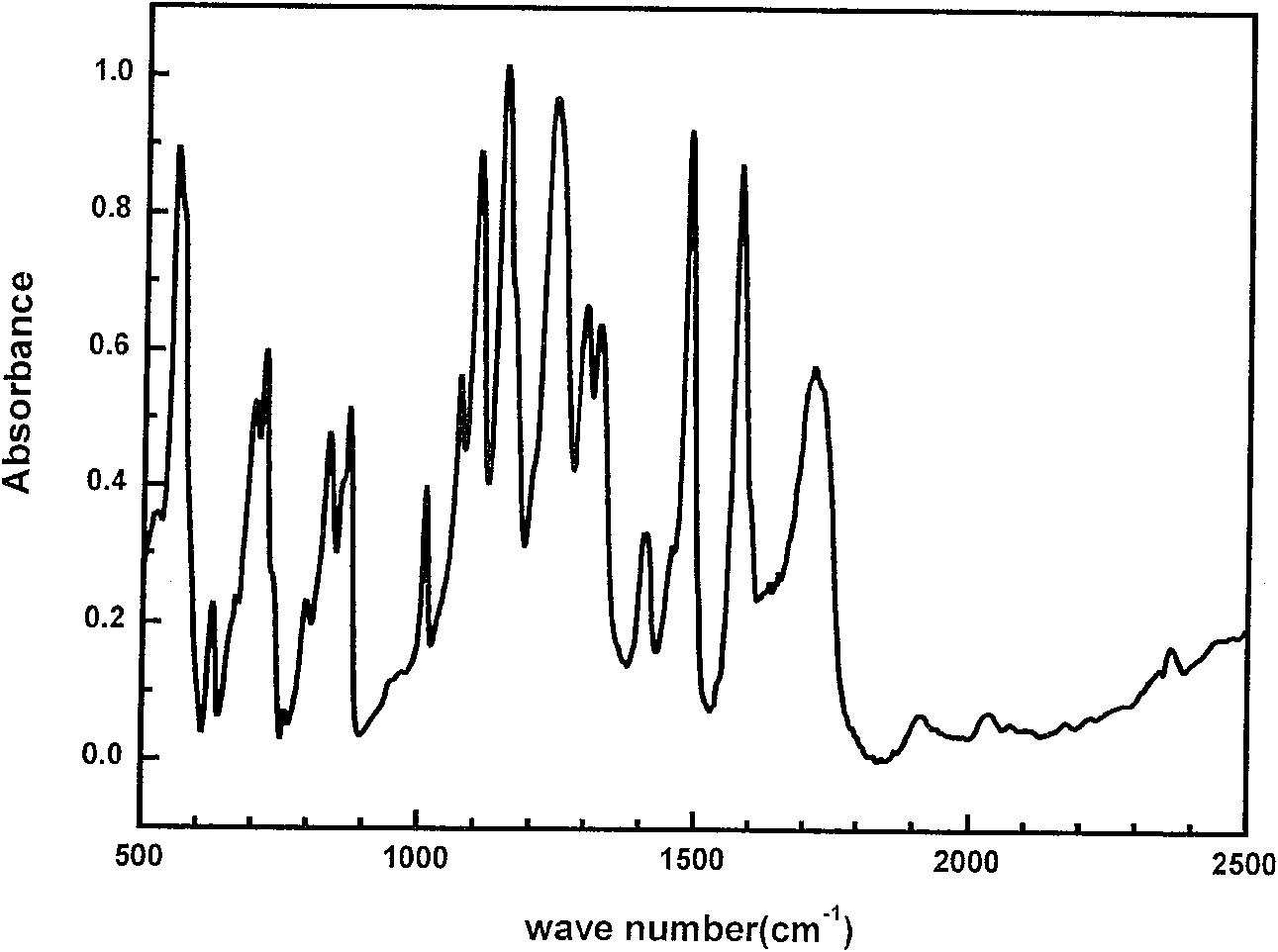

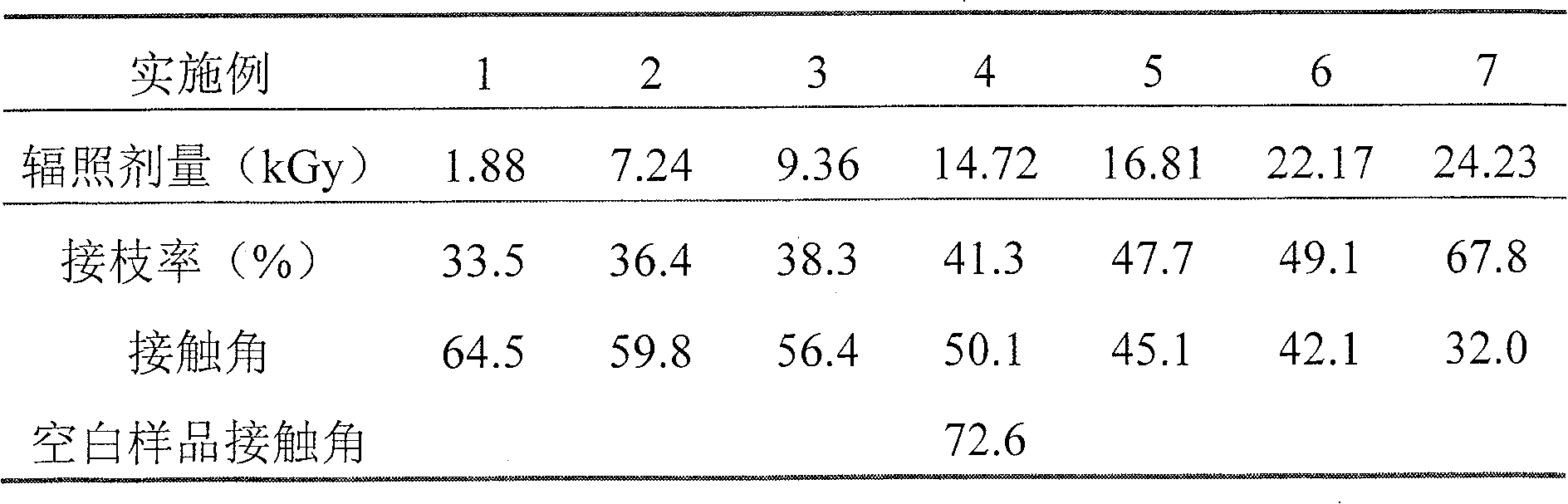

[0039] Put 5g of pretreated polyethersulfone powder into the irradiation tube, add 40ml, 50% (v / v) acrylic acid aqueous solution (PES: acrylic acid monomer is 5: 21.04), and then add CuSO 4As a polymerization inhibitor, the concentration in the reaction system is 0.004 mol / L, and the pH value of the system is adjusted to 1.0 with 1 mol / L HCl aqueous solution. Then the irradiation tube was placed under the cobalt source for irradiation, and the experiments with different cobalt source irradiation total doses were set for irradiation modification (as shown in Table 1), and the average dose rate was 0.324kGy / h. The sample was taken out, extracted with triple distilled water for more than 72 hours, and dried in a vacuum oven at 100 degrees Celsius to constant weight.

[0040] The contact angle of water on the surface of the modified PES powder was measured with a contact angle meter; and the grafting rate of the PEI powder was calculated. The test results are shown in Table 1.

...

Embodiment 8~10

[0044] The total cobalt source irradiation dose was set to 5kGy, and different average dose rates were set for irradiation modification (as shown in Table 2). The rest are the same as in Example 1, and the test results are shown in Table 2.

[0045] The embodiment of table 2 different average dose rates

[0046]

Embodiment 11~15

[0048] Put 5g of pretreated polyethersulfone powder into the irradiation tube, add 40ml of acrylic acid aqueous solution with different proportions (w / w) and volume concentration (as shown in Table 3), put the irradiation tube under the cobalt source for irradiation Irradiation dose is 15kGy, and the average dose rate is 0.324kGy / h, the remainder is the same as in Example 1, and the results are shown in Table 3.

[0049] The embodiment of table 3 different proportions and concentration monomer

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com