High-brightness PDP red fluorescent material, and its preparing method

A red fluorescence, high-brightness technology, used in luminescent materials, chemical instruments and methods, etc., can solve the problems of poor color purity and affecting the color rendering range of the picture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Starting materials: yttrium oxide, europium oxide, bismuth oxide, boric acid

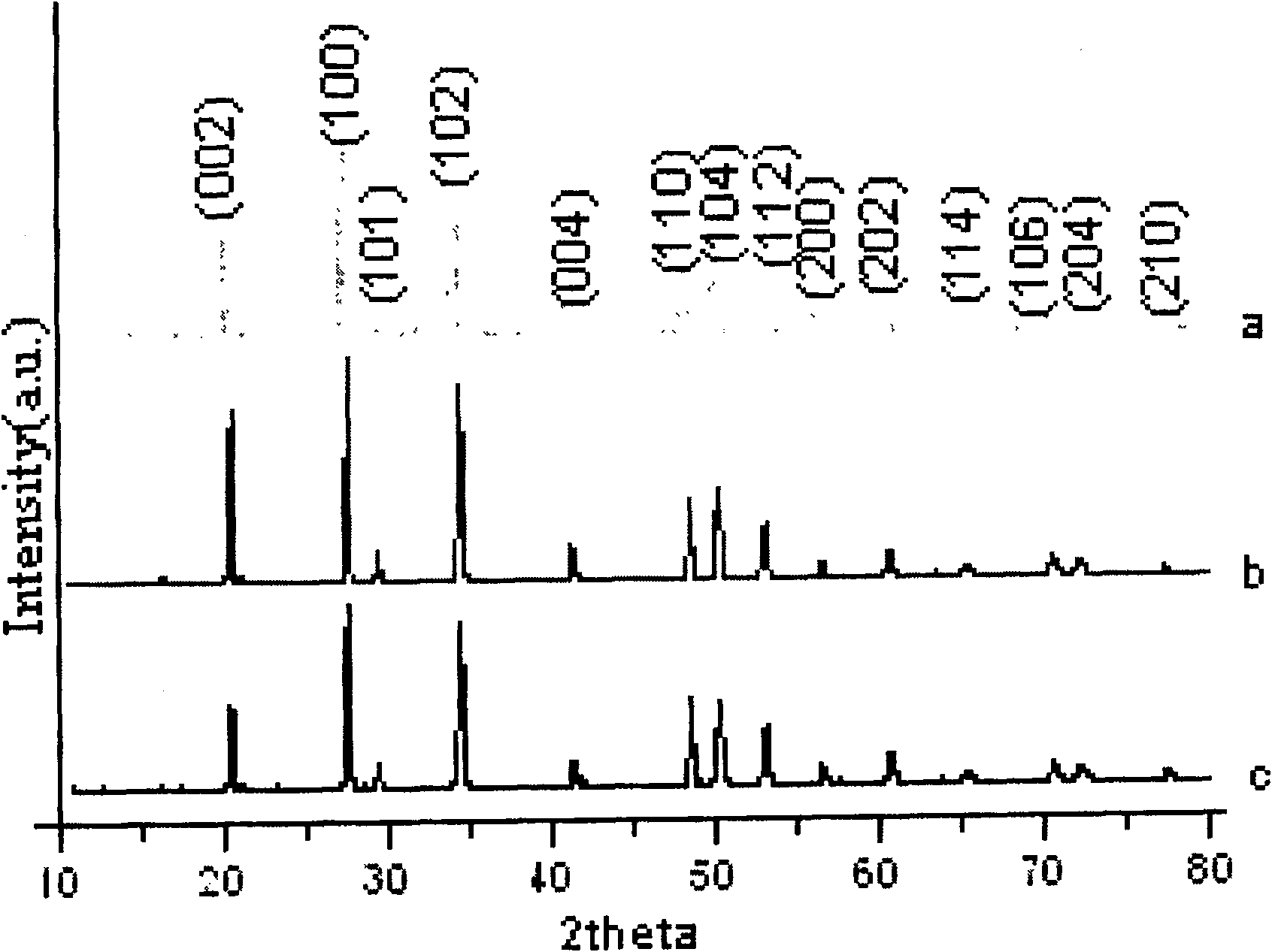

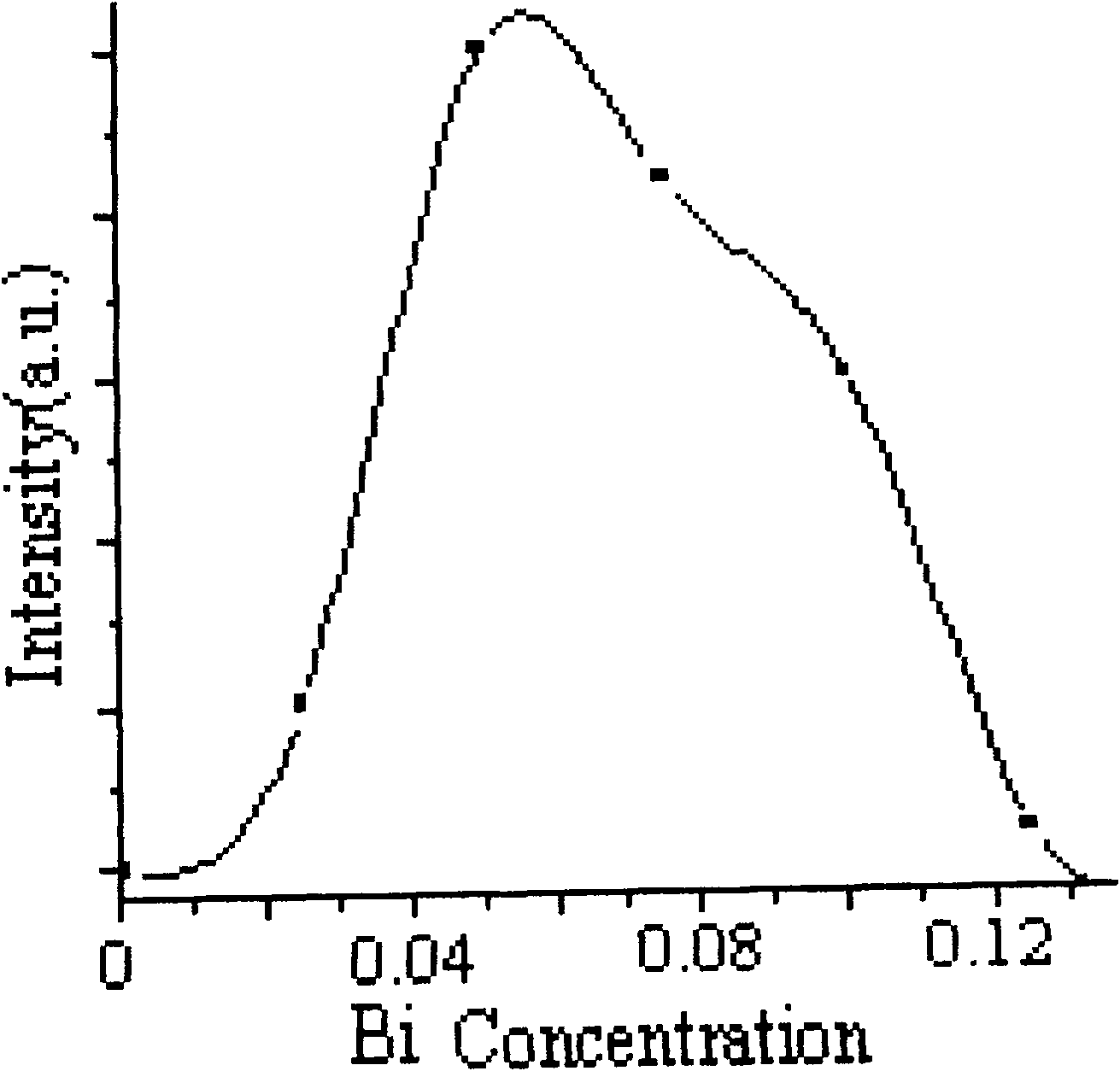

[0035] Raw materials are stoichiometrically ratio Y 0.9-x Bi x BO 3 :Eu 3+ (0≤x≤0.1) Accurately weighed, 10% of boric acid is excessive to supplement the loss of volatilization at high temperature. After grinding and mixing the raw materials evenly, first keep warm at 400-600°C for 2.5 hours, and then keep warm at 1000-1200°C for 3 hours hour, the product Y was obtained 0.9-x Bi x BO 3 :Eu3+ (0≤x≤0.1).

Embodiment 2

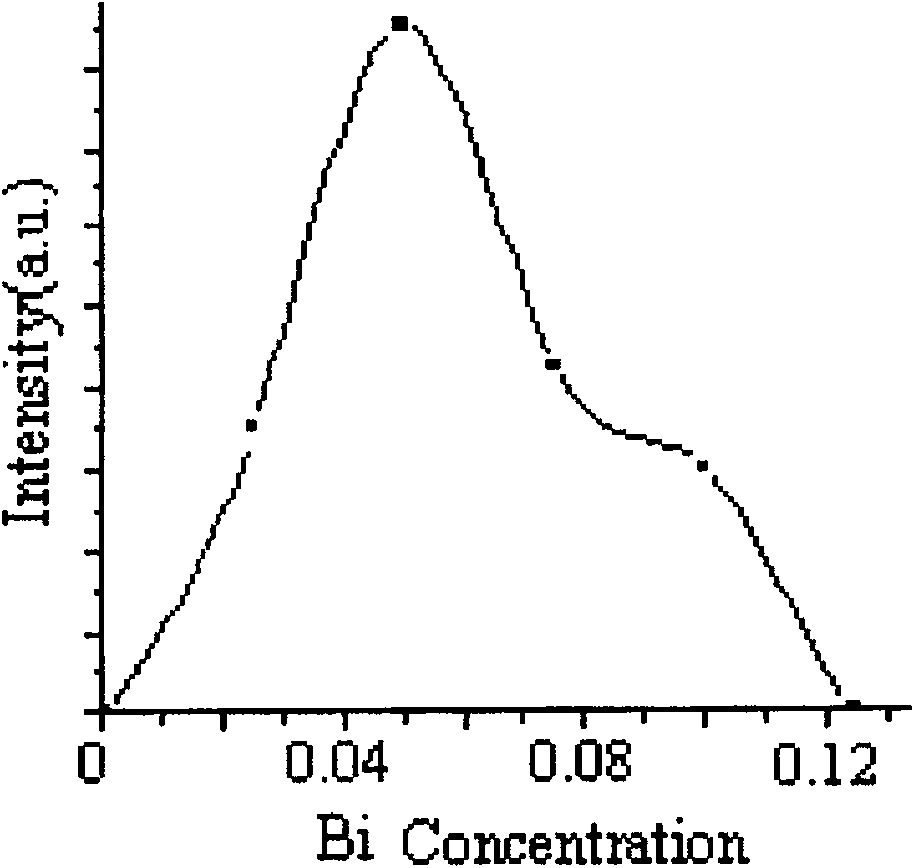

[0037] Starting materials: yttrium oxide, europium oxide, lanthanum oxide, boric acid

[0038] Raw materials are stoichiometrically ratio Y 0.9-x La x BO 3 :Eu 3+ (0≤x≤0.1) Accurately weighed, 10% of boric acid is excessive to supplement the loss of volatilization at high temperature. After grinding and mixing the raw materials evenly, first keep warm at 400-600°C for 2.5 hours, and then keep warm at 1000-1200°C for 3 hours hour, the product Y was obtained 0.9-x La x BO 3 :Eu 3+ (0≤x≤0.1).

Embodiment 3

[0040] Starting materials: yttrium oxide, europium oxide, scandium oxide, boric acid

[0041] Raw materials are stoichiometrically ratio Y 0.9-x sc x BO 3 :Eu 3+ (0≤x≤0.1) accurately weighed, wherein boric acid is over 10% to supplement the loss of volatilization at high temperature. After grinding and mixing the raw materials evenly, first keep warm at 400-600°C for 2.5 hours, and then keep warm at 1000-1200°C for 3 hours to obtain the product Y 0.9-x sc x BO 3 :Eu 3+ (0≤x≤0.1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com