Portable electromagnetic ultrasonic crack detector for locomotive wheel pair tread

An electromagnetic ultrasonic and flaw detector technology, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and instruments. It can solve the problems of long detection time, inconvenient application of on-site detection, and low efficiency. , to achieve the effect of easy portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

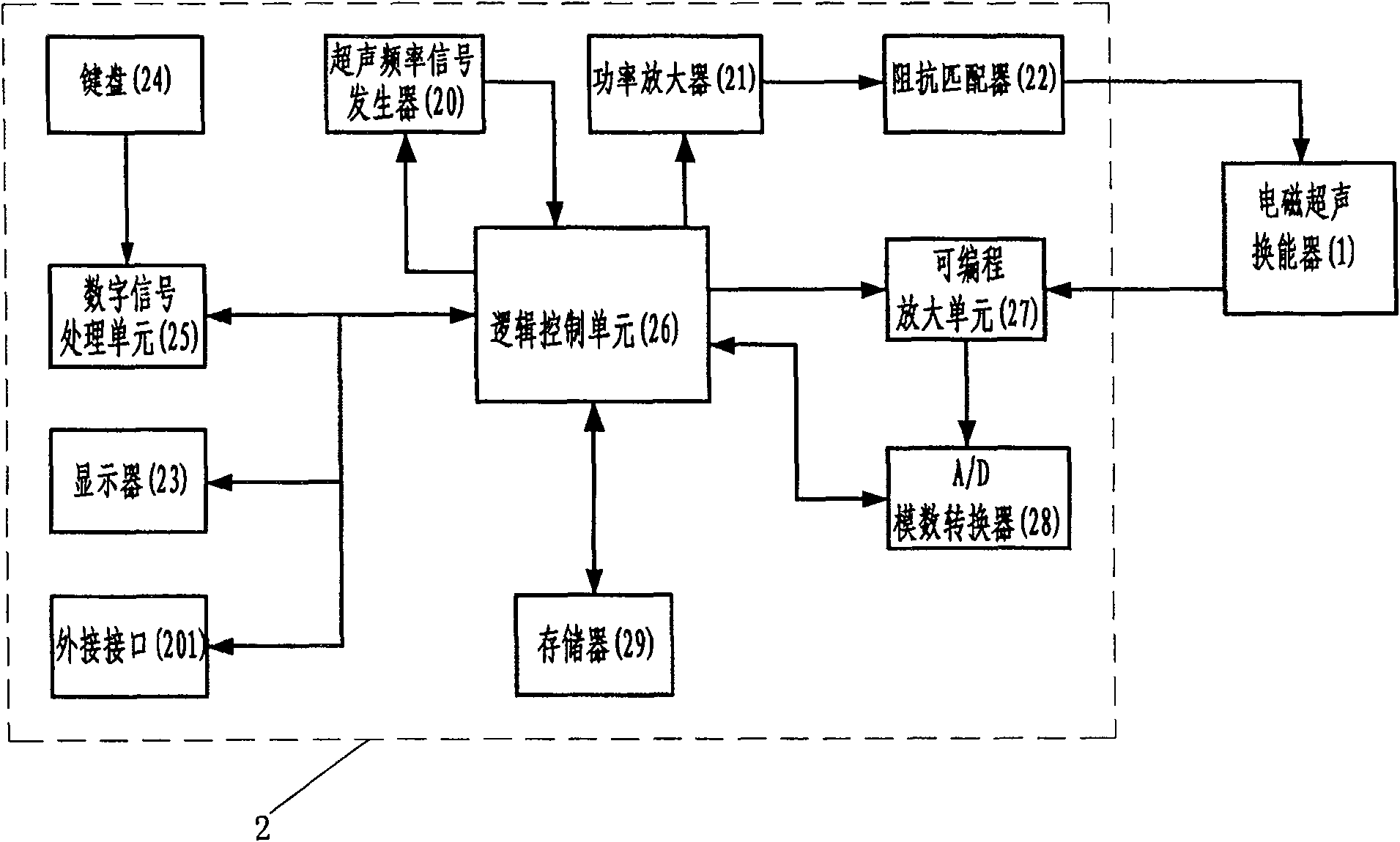

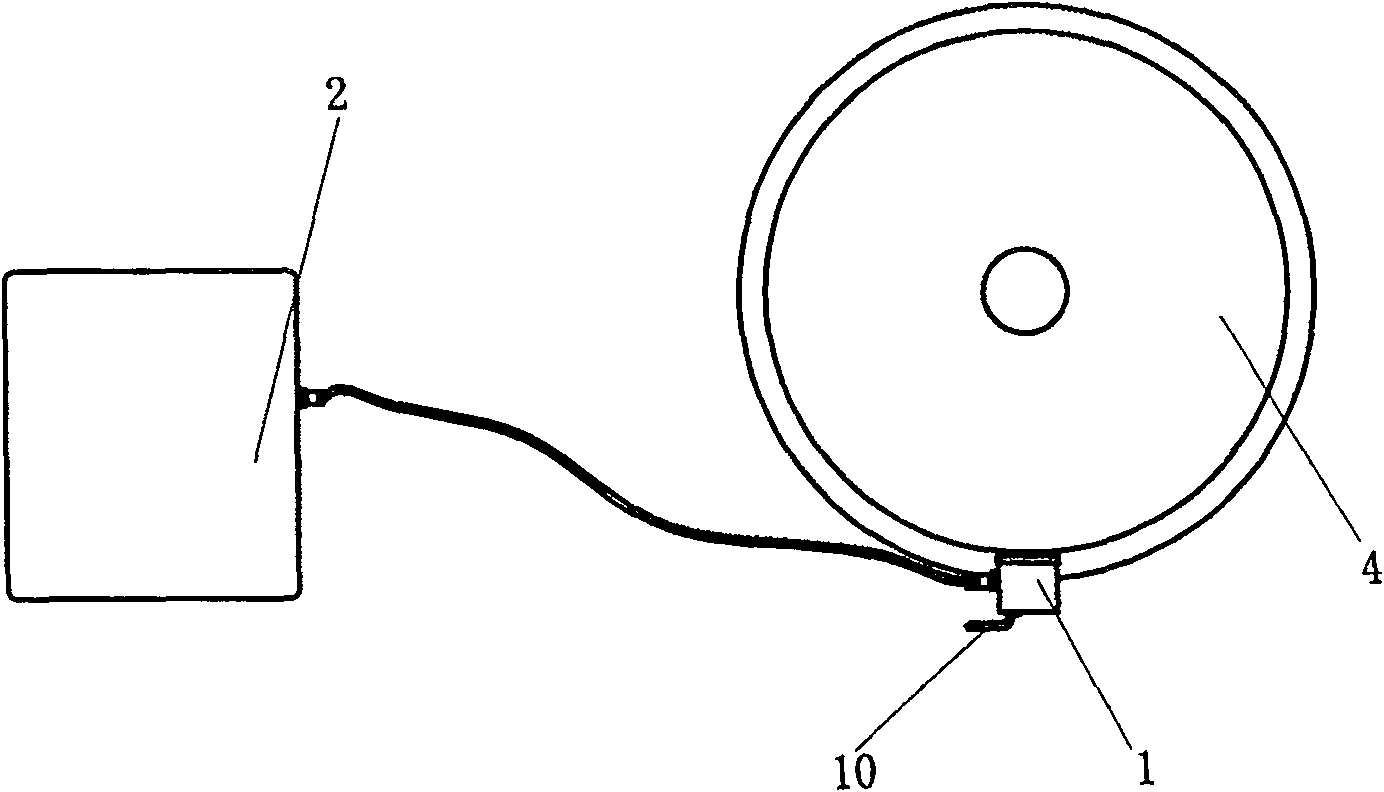

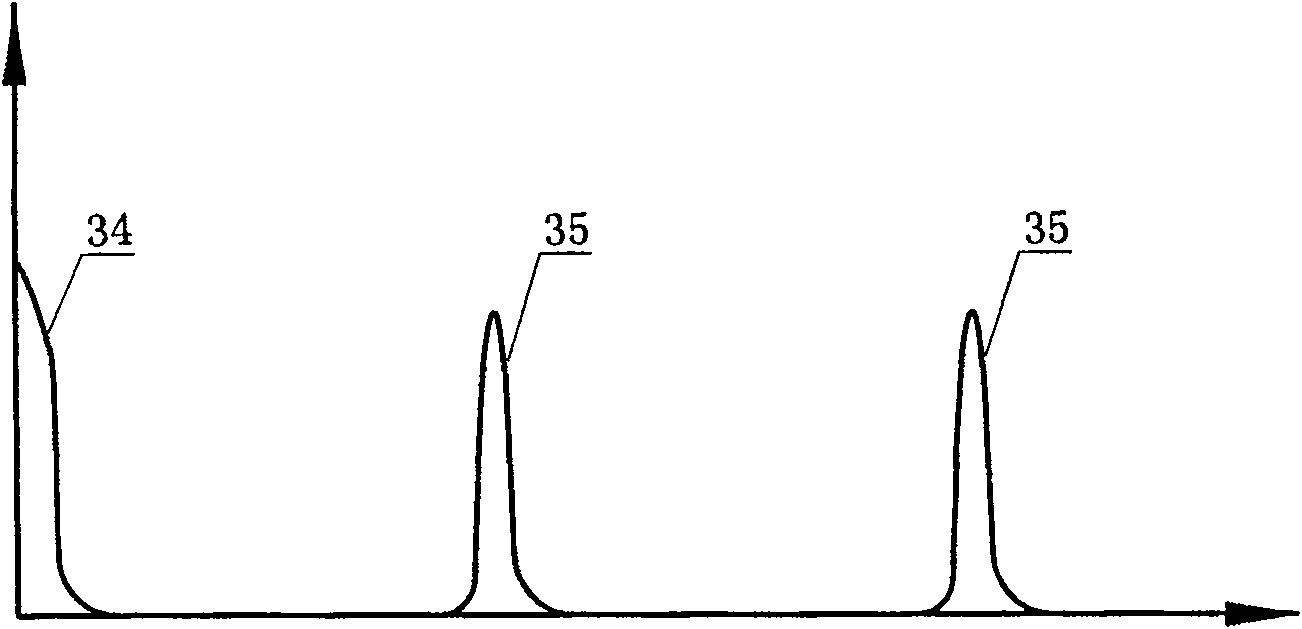

[0032] figure 1 , figure 2 As shown, a specific embodiment of the present invention is: a portable electromagnetic ultrasonic flaw detector for the tread of locomotive and vehicle wheels, which is composed of a flaw detector host 2 and an electromagnetic ultrasonic transducer 1, and is characterized in that: the flaw detector host 2 The ultrasonic frequency signal produced by the ultrasonic frequency signal generator 20 in the middle is sent to the power amplifier 21 to amplify through the logic control unit 26; The ultrasonic surface wave propagates along the wheel-set surface, and the ultrasonic surface echo is received by the electromagnetic ultrasonic transducer 1; after being amplified by the programmable amplifying unit 27 in the host computer 2, it is converted into A digital signal, the digital signal is directly sent to the memory 29 for storage through the logic control unit 26 , processed by the digital signal processing unit 25 and then sent to the memory 29 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com