Through wall device for screening wire of electromagnetic screening chamber

An electromagnetic shielding and network cable technology, applied in the direction of magnetic field/electric field shielding, electrical components, etc., can solve problems such as poor contact, difficulty in building structure and structured wiring technology, and reduced shielding performance, and achieve the effect of simple structure and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

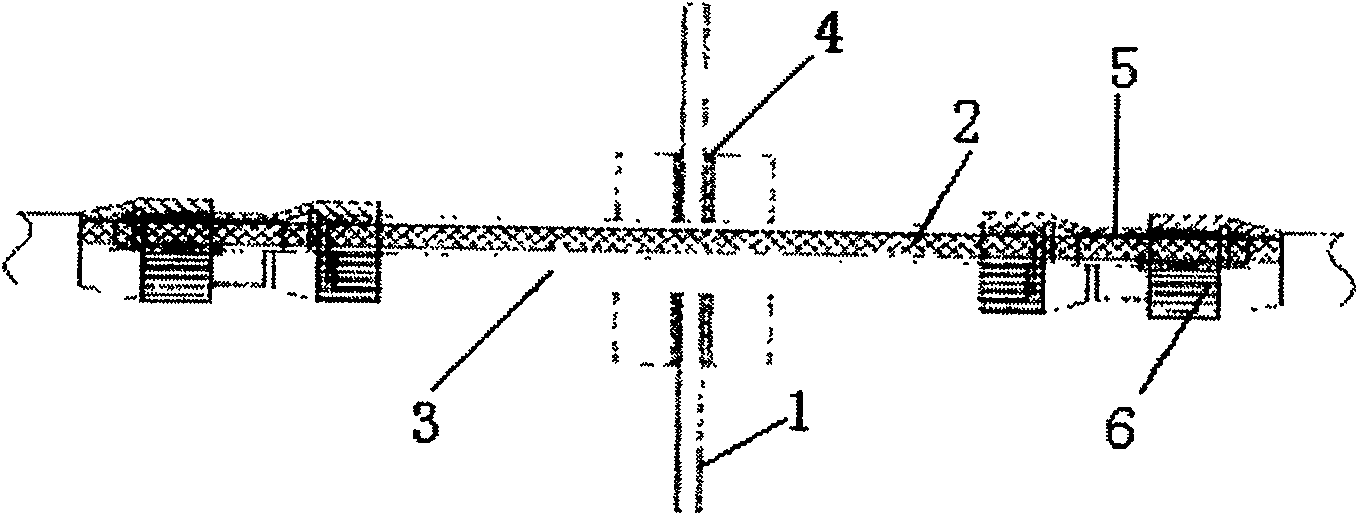

[0022] The embodiment that adopts threading waveguide of the present invention is as follows:

[0023] 1. Drill a fine-pitch screw hole with the same outer diameter as the waveguide on the wall plate, and polish off the anti-corrosion layer of the steel plate within 1cm around. If it is an autocratic copper-plated steel plate, it only needs to be cleaned with alcohol;

[0024] 2. Screw in the waveguide to the center position;

[0025] 3. Pad the gaskets made of 200-mesh copper mesh at both ends, and fix the two pressing pieces to make them compact;

[0026] 4. Strip the insulation of the network cable to expose the copper wire shielding layer, wrap it with 200-mesh copper wire mesh, and stuff it into the waveguide. The stripped length should exceed the length of the center chuck;

[0027] 5. Tighten the center chuck;

[0028] 6. Tighten the locking head.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com