Multi-laminar flow cribriform-plate-free boiling chloridization furnace

A boiling chlorination furnace, no sieve plate technology, applied in the direction of titanium halide, chemical instruments and methods, chemical/physical process, etc. The effect of easy temperature control, long running time and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

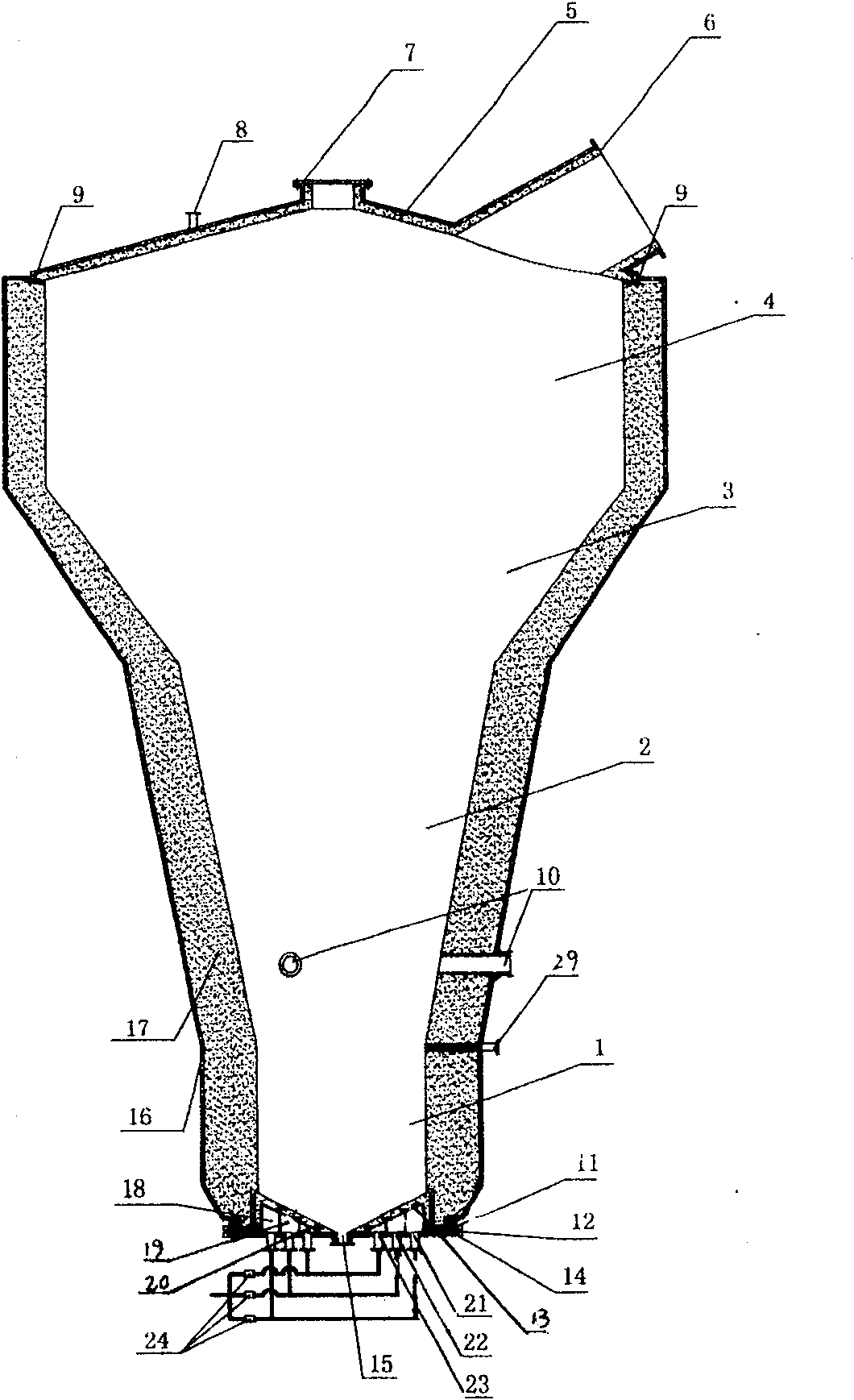

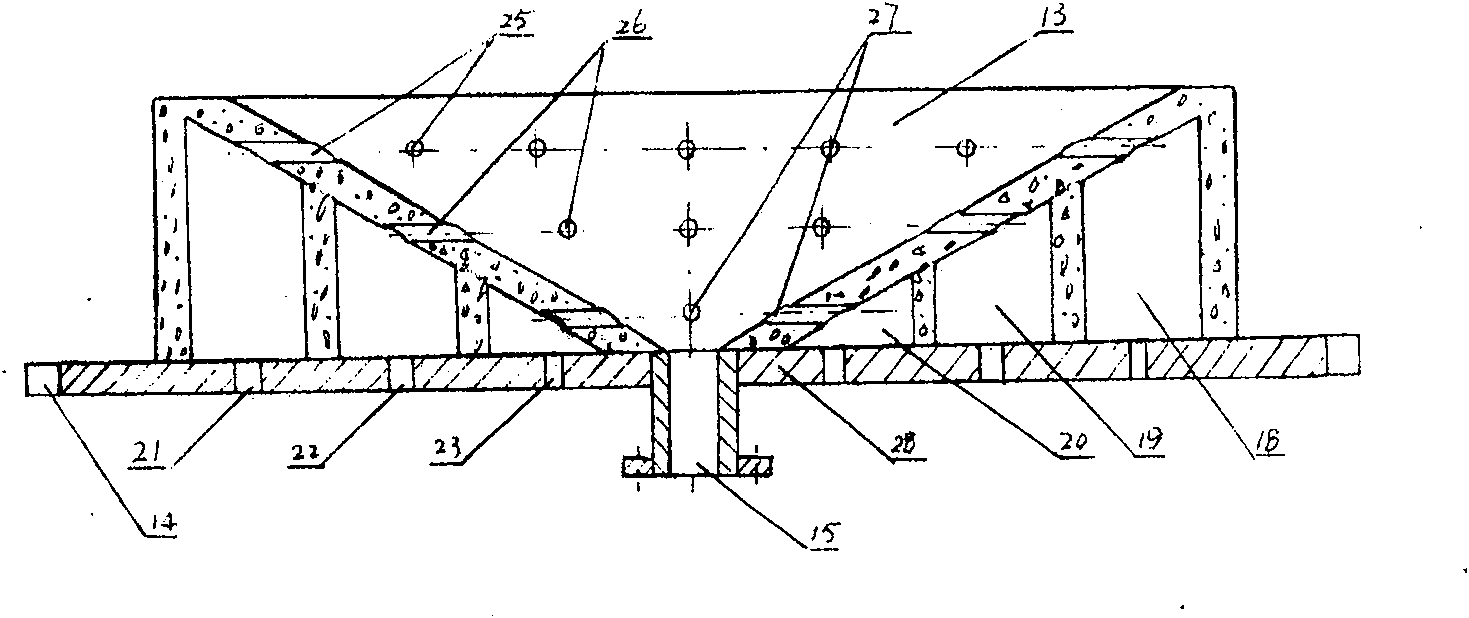

[0012] figure 1 It is a cross-sectional view of the multilayer flow fluidized chlorination furnace without sieve plate of the present invention. The furnace body of the chlorination furnace is cylindrical and conical, and is composed of an outer steel shell 16 and a furnace lining 17 lined with refractory materials. The furnace cover 5 is an inverted cone , the furnace cover 5 is equipped with a gas outlet 6, an explosion-proof port 7, and a temperature measuring port 8. The connection between the furnace cover 5 and the furnace body is a self-weight compression connection, and the joint is sealed with a refractory gasket 9, and the furnace body is from bottom to top Divided into four sections, the first furnace section 1 is conical, its upper part is equipped with a temperature measuring port 29, and its lower part has a flange 11 and a furnace bottom flange 14 fastened to the furnace bottom 13 with bolts. There is an elastic sealing ring 12 between the flanges 14 of the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com