Pavement planeness automatic detection method

An automatic detection and flatness technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of low measurement efficiency, signal aliasing, and many error sources, and achieve high detection efficiency, eliminate signal aliasing, and error source less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

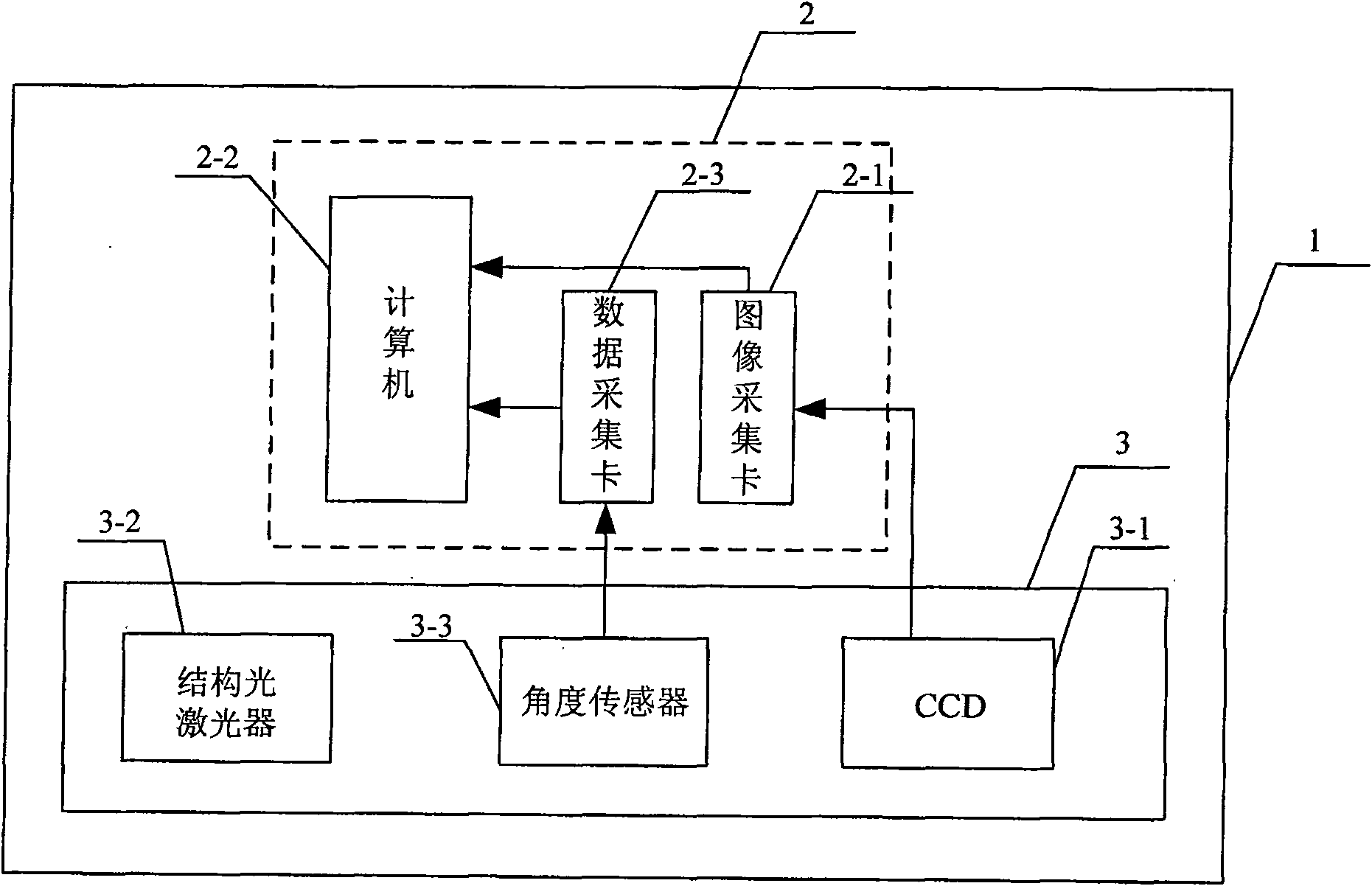

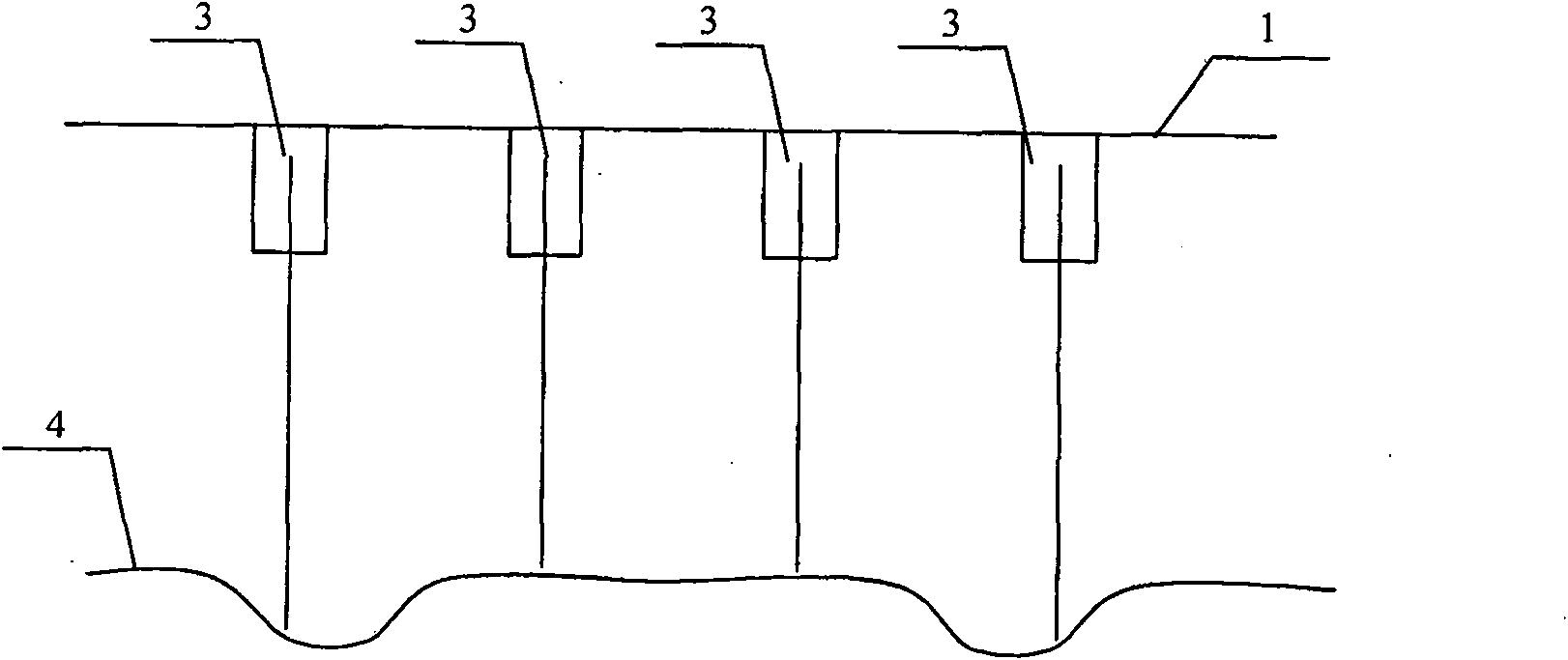

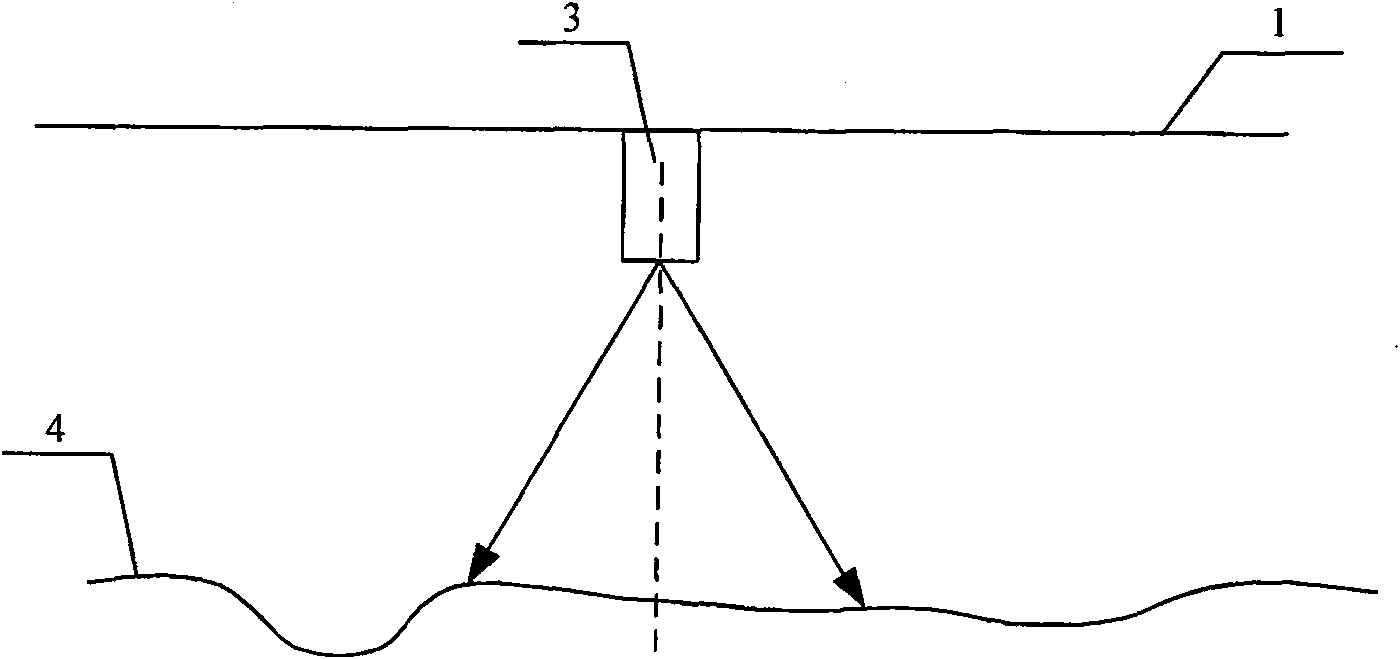

[0021] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment. This embodiment is composed of a processing system 2 and a three-dimensional structured light vision detection component 3. The three-dimensional structured light vision detection component 3 is arranged laterally on the cross section of the bottom of the car body 1. The three-dimensional structured light vision detection component 3 includes a structure The optical laser 3-2 and the area array CCD3-1 are characterized in that the structured light strips emitted by the structured light laser 3-2 cover the longitudinal road surface, and the camera of the area array CCD3-1 faces the road surface 4 below the structured light laser 3-2, so as to Shoot the light strip image projected by the structured light laser 3-2 onto the road surface 4 and cover the longitudinal road surface; the three-dimensional structured light visual detection component 3 also includes an angle sensor 3-3; the o...

specific Embodiment approach 2

[0022] Specific implementation mode two: combination figure 1 Illustrate the present embodiment, present embodiment and specific embodiment one difference is that processing system 2 is made up of image acquisition card 2-1, data acquisition card 2-3 and computer 2-2; The output terminal connection image of area array CCD3-1 The input end of the acquisition card 2-1, the image acquisition card 2-1 is connected to the inside of the computer 2-2, the output end of the angle sensor 3-3 is connected to the input end of the data acquisition card 2-3, and the output of the data acquisition card 2-3 The terminal is connected to the inside of the computer 2-2. Other compositions and connection methods are the same as those in Embodiment 1. Image acquisition card 2-1 adopts OK_M20A from Beijing Jiaheng Zhongzi, data acquisition card 2-3 adopts Taiwan Advantech PCI-1710L, computer 2-3 adopts Taiwan Advantech industrial computer.

specific Embodiment approach 3

[0023] Specific implementation mode three: combination Figure 4 Describe this embodiment, the difference between this embodiment and the specific embodiment is that the angle sensor 3-3 is arranged at the position between the structured light laser 3-2 and the area array CCD3-1; other composition and connection methods are the same as the specific embodiment one same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com