Calibrating method of binocular three-dimensional measuring system

A technology of measurement system and calibration method, which is applied in the field of measurement and testing, can solve the problems that the calibration accuracy is difficult to reach industrial measurement, achieve high-precision calibration effect, and reduce the effect of production and measurement calibration requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation steps of the internal and external parameter calibration method of the binocular stereo measurement system proposed by the present invention will be further described below.

[0019] Step 1. Make a calibration plate and take a calibration image

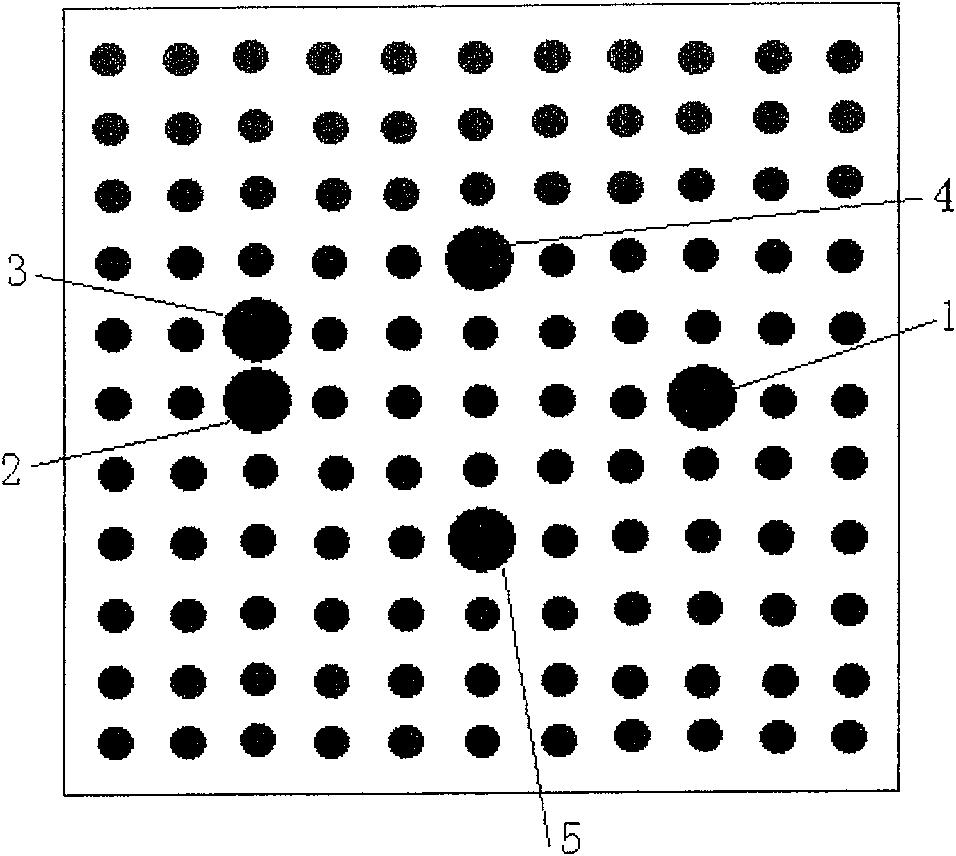

[0020] The present invention requires N rows and M columns of easily identifiable characteristic dots to be distributed on the calibration plate, wherein the diameters of five characteristic dots are obviously larger than the diameters of other characteristic dots, and their relative positions in the array can distinguish their respective Identity, the calibration board does not have strict flatness requirements, and the position of each feature point does not need to be accurately measured, as long as the distance between two points on the calibration board is accurately known. figure 1 is an example of a calibration board. For the 5 characteristic dots, as long as each of the five is different fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com