Sealing method of blast furnace cooling wall joint and its used sealing part

A technology for cooling walls and sealing parts, applied in the direction of cooling devices, etc., can solve problems such as hidden safety hazards, inability to implement technology, affecting the placement of new cooling walls, etc., and achieve the effect of not easily falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

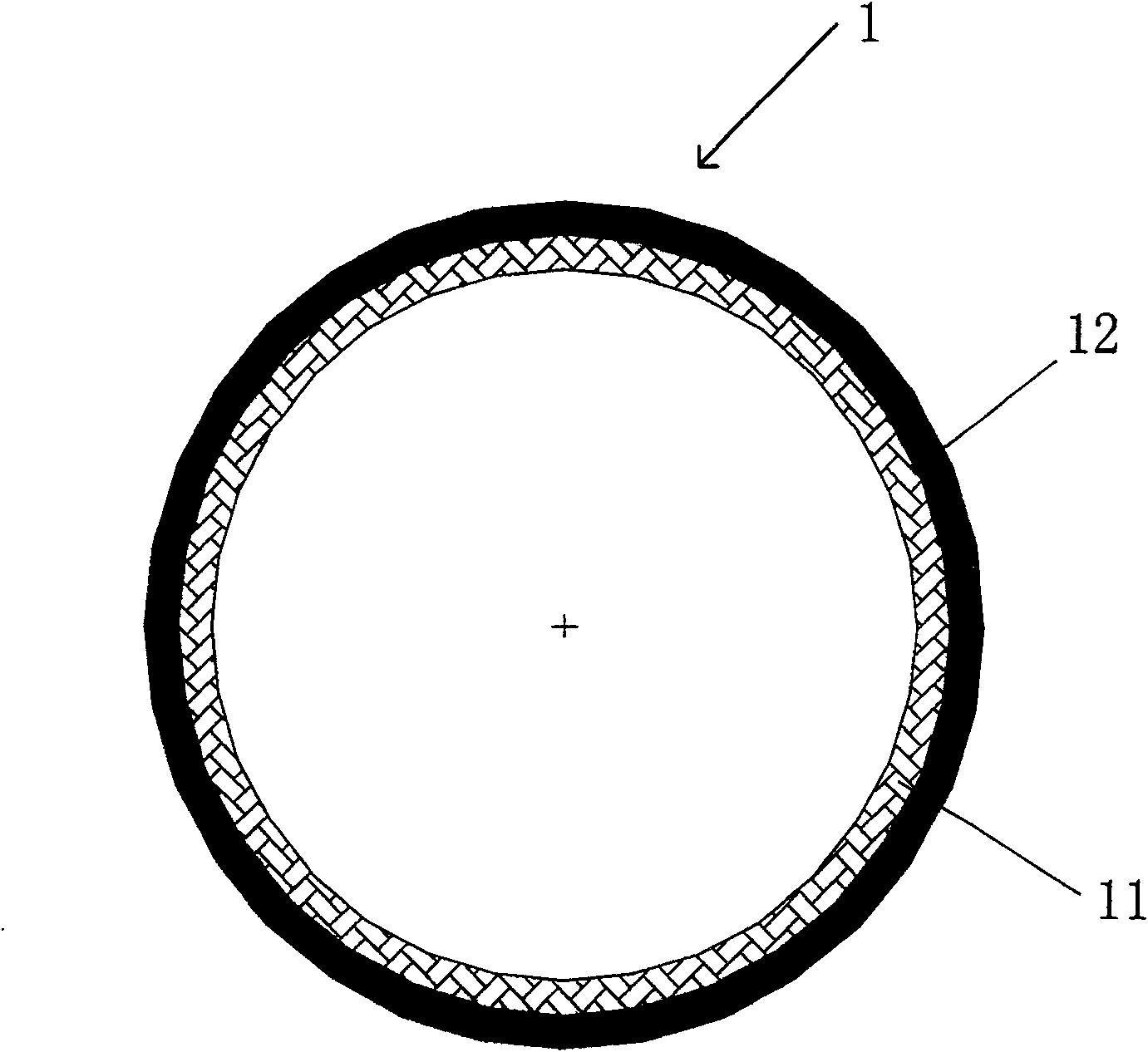

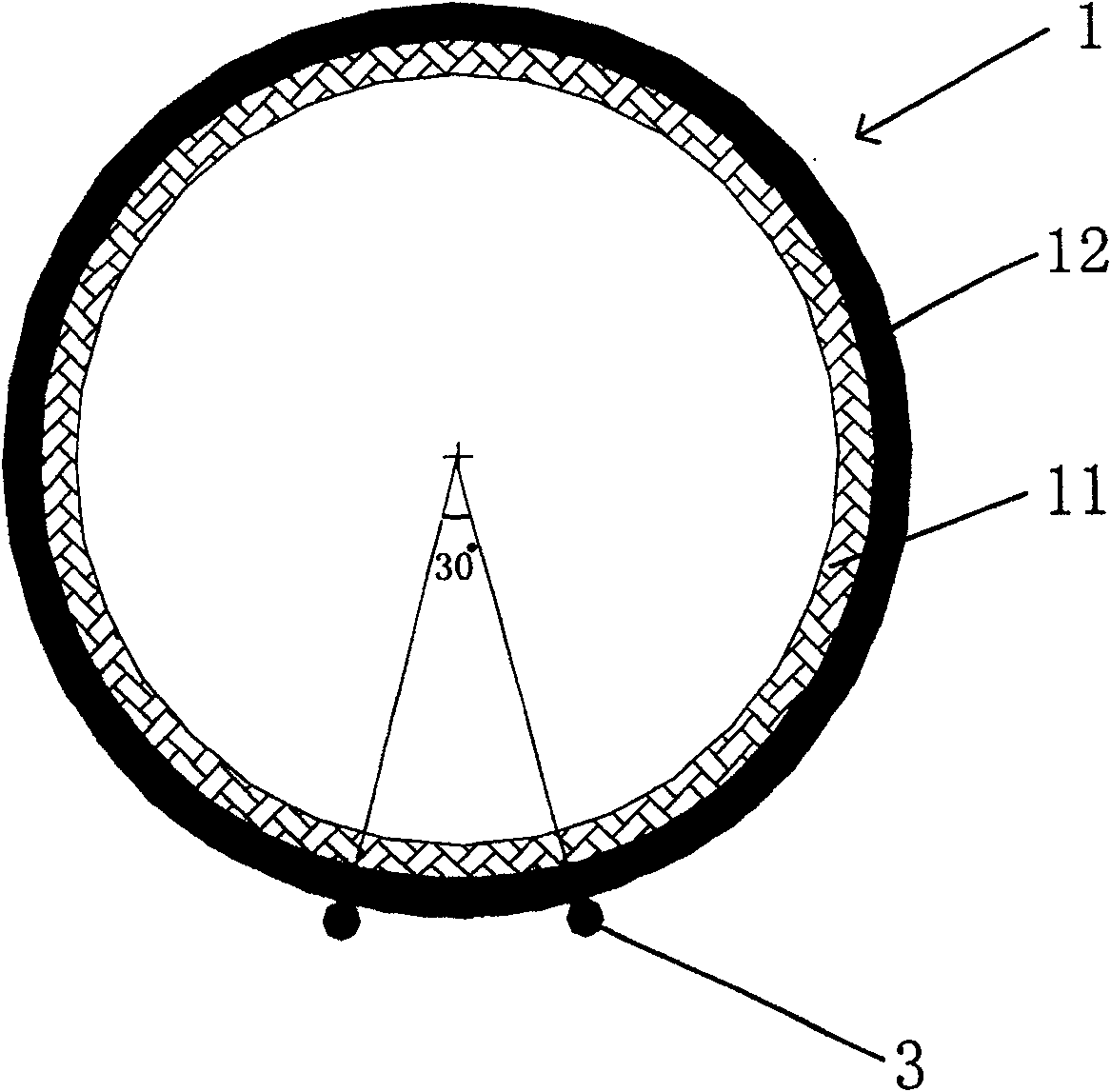

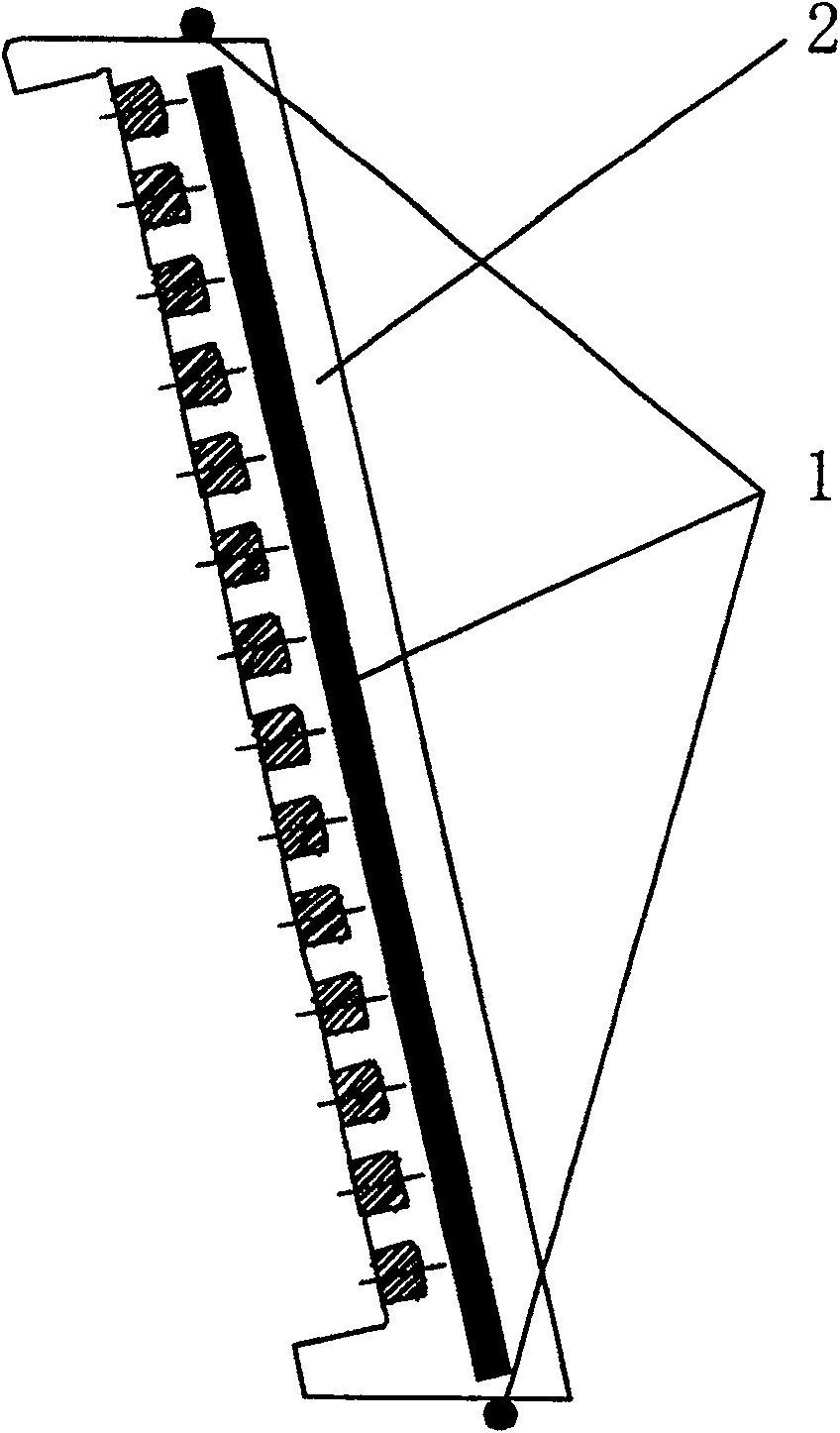

[0022] Figure 1-Figure 3 It is a preferred embodiment of the present invention. In order to achieve the above-mentioned purpose of the present invention, the design concept of the present invention is: firstly, after the seal is installed on the stave, it can effectively block the seam between the staves, so the seal of the seal The diameter should be equal to the width of the joint; secondly, since the newly replaced stave is operated by the construction personnel outside the furnace to make it in place in the furnace, in order to ensure its smooth installation in place, the seal cannot hinder the installation of the new stave. Therefore, it must be designed with a certain degree of flexibility in the rigidity; finally, the seal needs to block the sprayed material and the press-in material at the same time, the sprayed material in the furnace must adhere to the seal, and the press-in material on the back of the cooling wall cannot Penetrate the seal.

[0023] see figure 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com