Integrated semiconductor product comprising a metal-insulator-metal capacitor

一种金属电容器、半导体的技术,应用在电容器、半导体器件、固定电容器电介质等方向,能够解决表面积增加等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

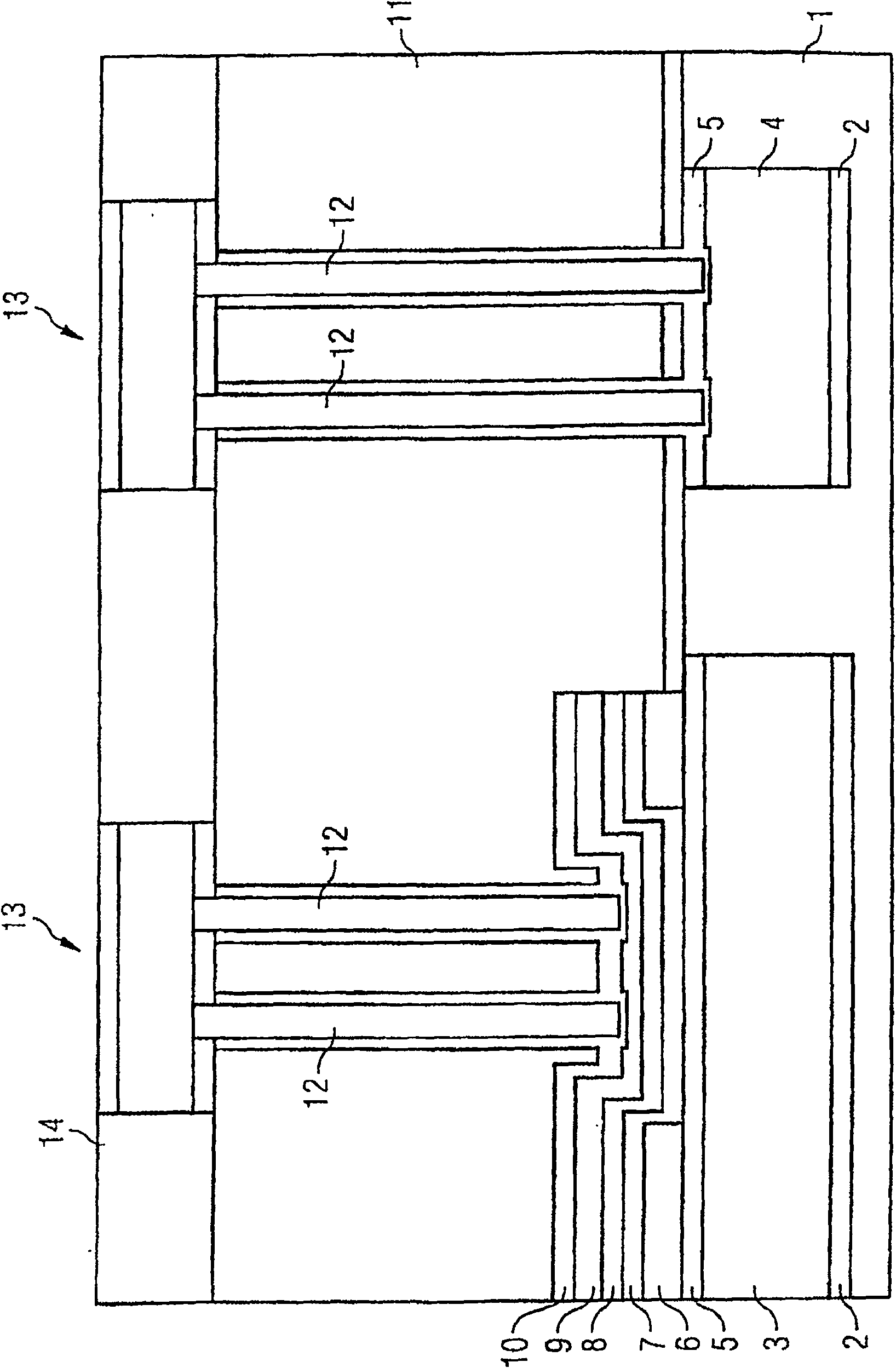

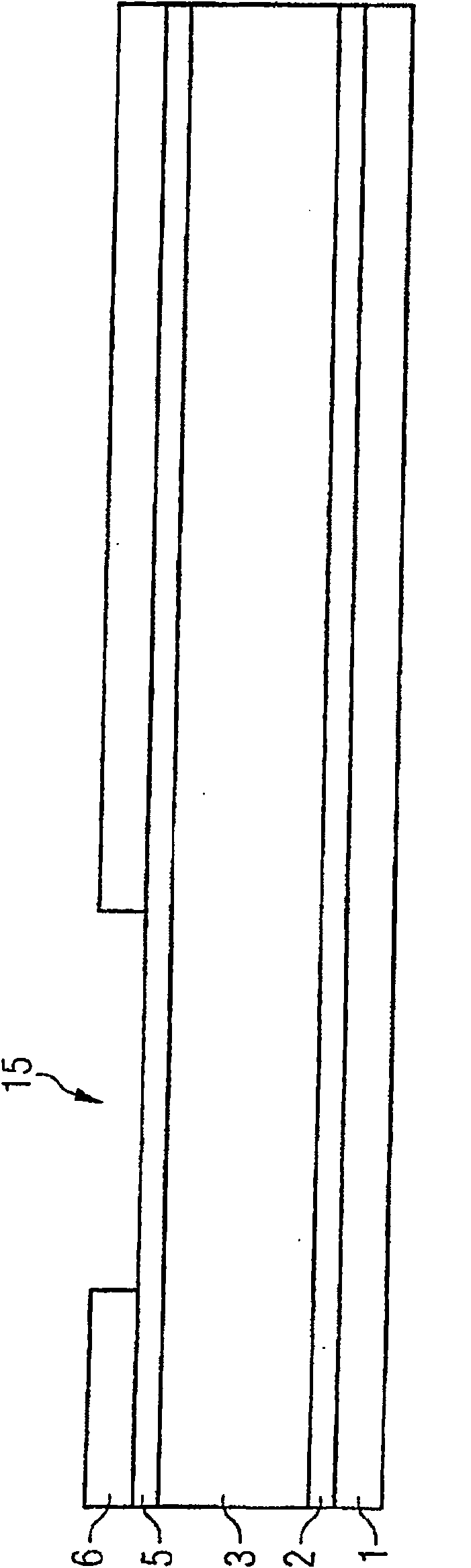

[0028] figure 2 A metal track stack is shown with a Ti glue layer 2, an AlCu interconnect 3, and an anti-reflective coating (ARC) layer 5, as used in the known art. In this example, the interconnection 3 is also intended to function as a lower MIM electrode, having a dielectric auxiliary layer 6 of about 50 to 100 nm thickness, for example made of SiO 2 or Si 3 N 4 The fabricator is deposited on top of the metal track stack 2, 3, 4 by using procedures known to be suitable for metallization, as part of a sacrificial layer rather than acting as a MIM dielectric, But rather, it will become part of the intermetal dielectric (IMD) that will be applied subsequently. Then, using known lithography and etching methods, the dielectric assist layer is removed at location 15, where a MIM capacitor is intended to be integrated.

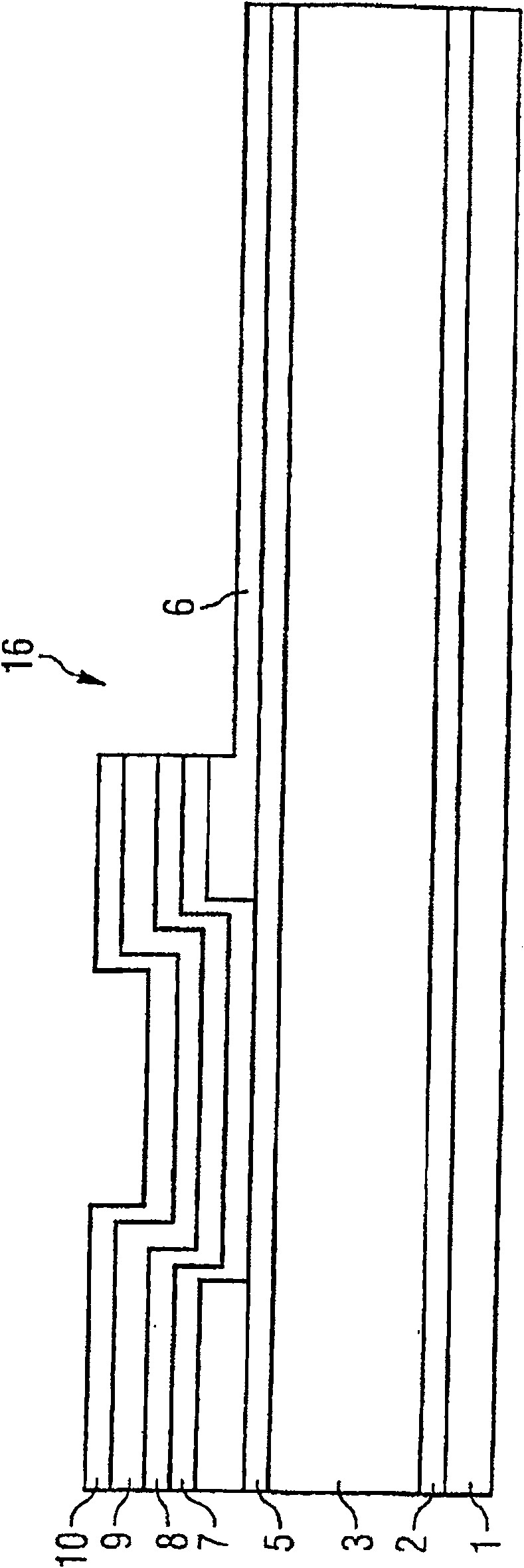

[0029] image 3 The MIM capacitor is shown after deposition and etching of the MIM dielectric 7 and the upper electrodes 8, 9, 10 have been performed. Now,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com