Micro-mechanical two-dimension wind speed and wind direction sensor and signal processing circuit thereof

A wind speed, wind direction, sensor technology, used in instruments, using thermal variables to measure fluid velocity, velocity/acceleration/impact measurement, etc., can solve the problems of easy wear and tear of mechanical devices, need frequent maintenance, and high prices, to avoid errors and sensitivity. and range optimization, the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

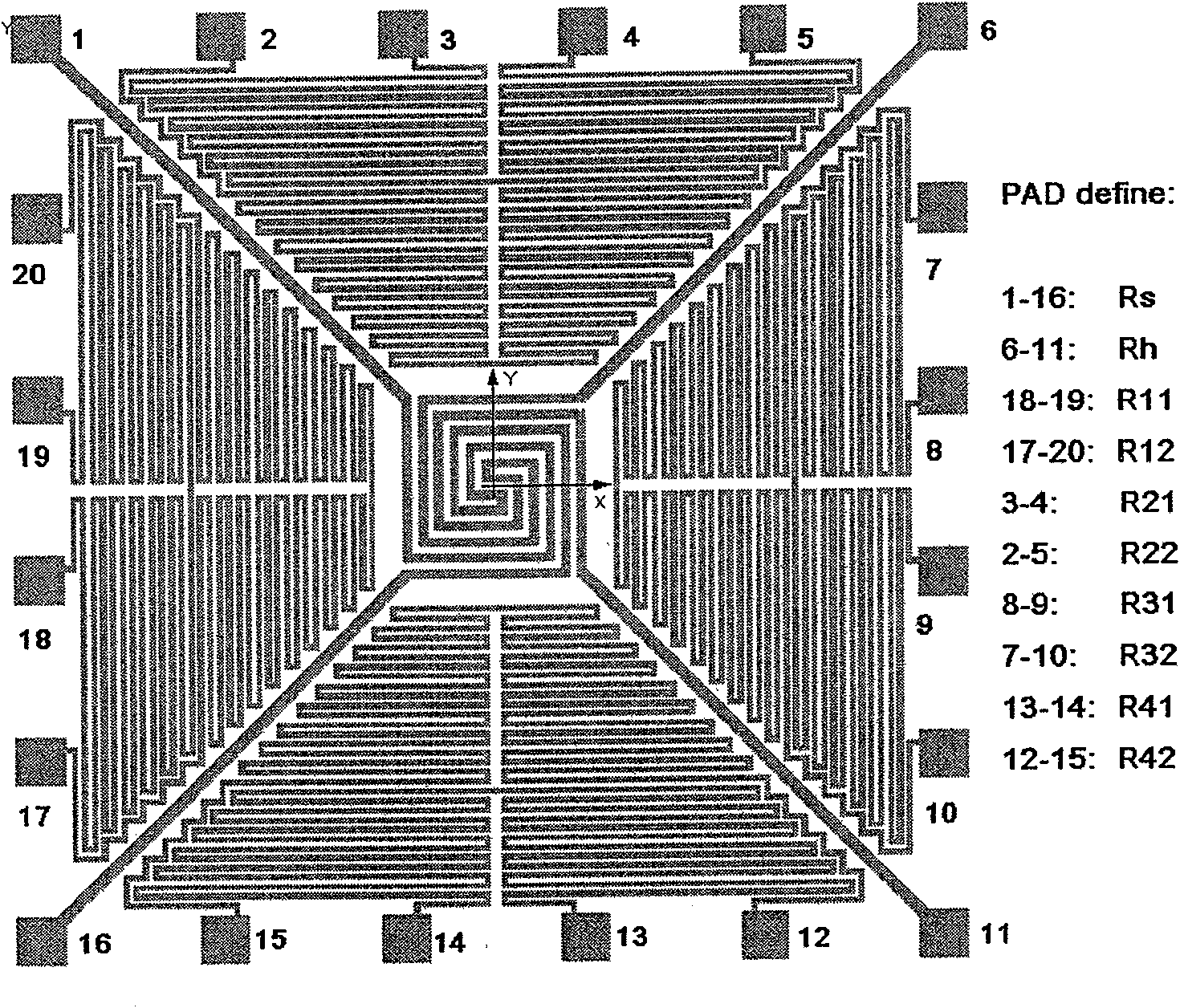

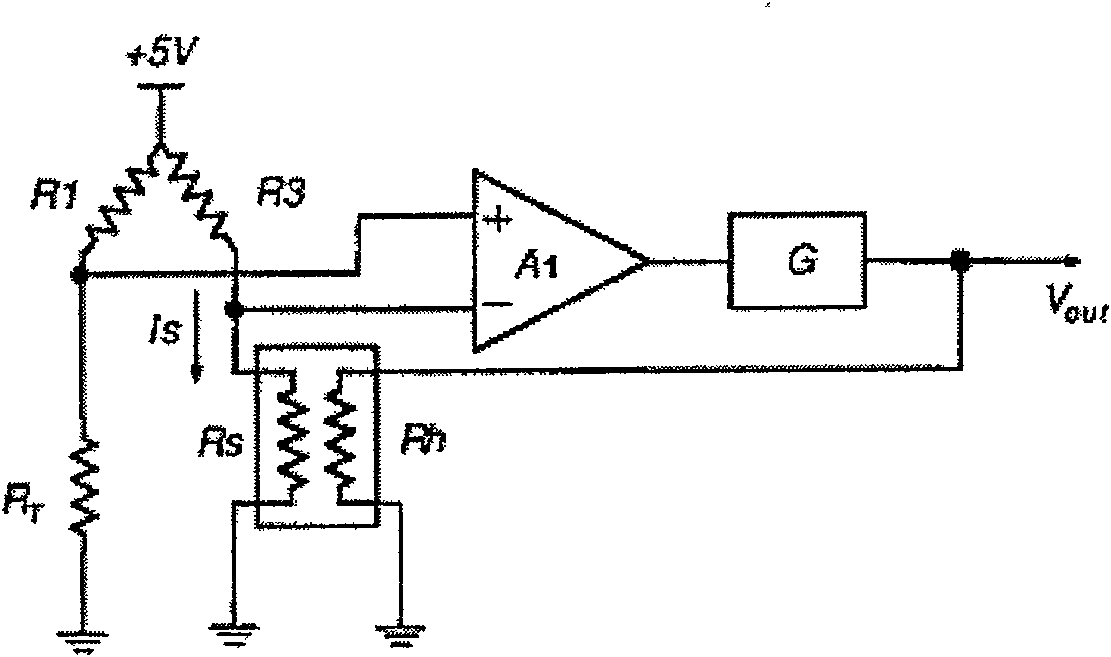

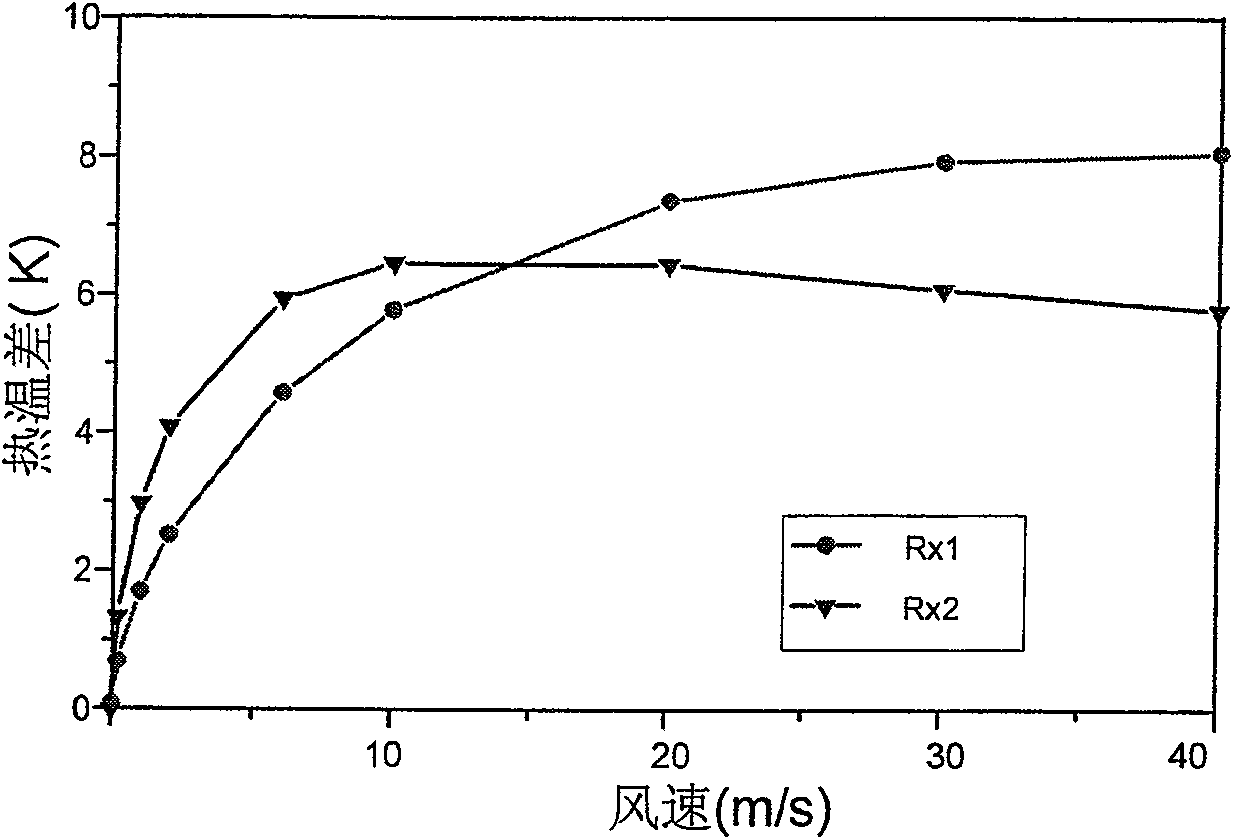

[0030] The two-dimensional wind speed and wind direction sensor proposed by the invention adopts the constant temperature difference working mode, and uses the thermal temperature difference principle to measure the wind speed and wind direction. In order to reduce the heat conduction of the substrate of the hot film wind speed sensor and improve the sensitivity of the sensor, the chip adopts a glass substrate with low thermal conductivity. At the same time, platinum with stable physical properties is used as the heating and temperature measuring element, which can be processed by stripping process. In order to facilitate bonding and wiring, a layer of gold is deposited on the pad.

[0031] The micromechanical two-dimensional wind speed and direction sensor of the present invention includes a heating resistor, a chip temperature measuring resistor, 8 thermal temperature difference measuring resistors and a welding block; the chip temperature measuring resistor and the heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com