Complete waveguide bandwidth standard waveguide output high power helix TWT

A bandwidth standard and helical technology, applied in the direction of traveling wave tubes, etc., can solve problems such as limited output power, poor heat dissipation, and difficult bandwidth adjustment, and achieve good matching performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

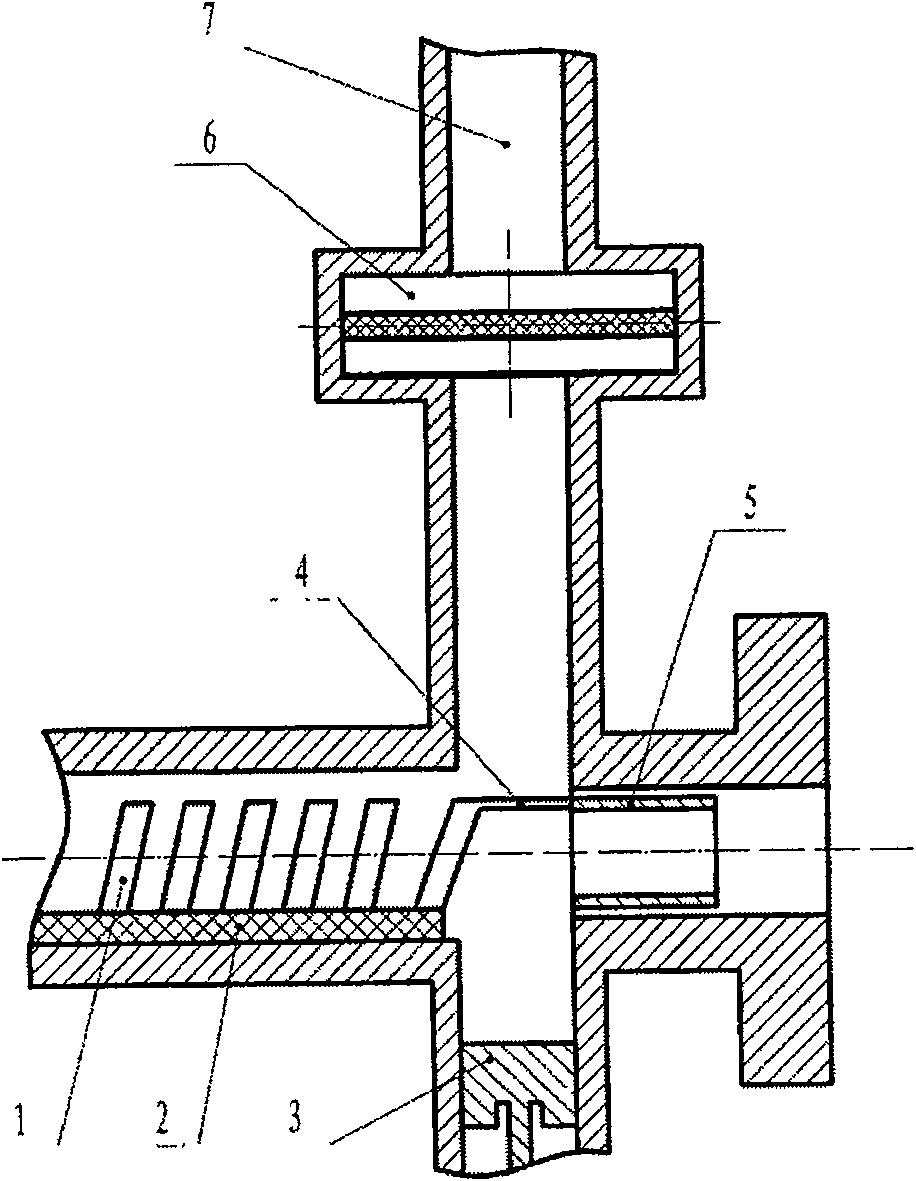

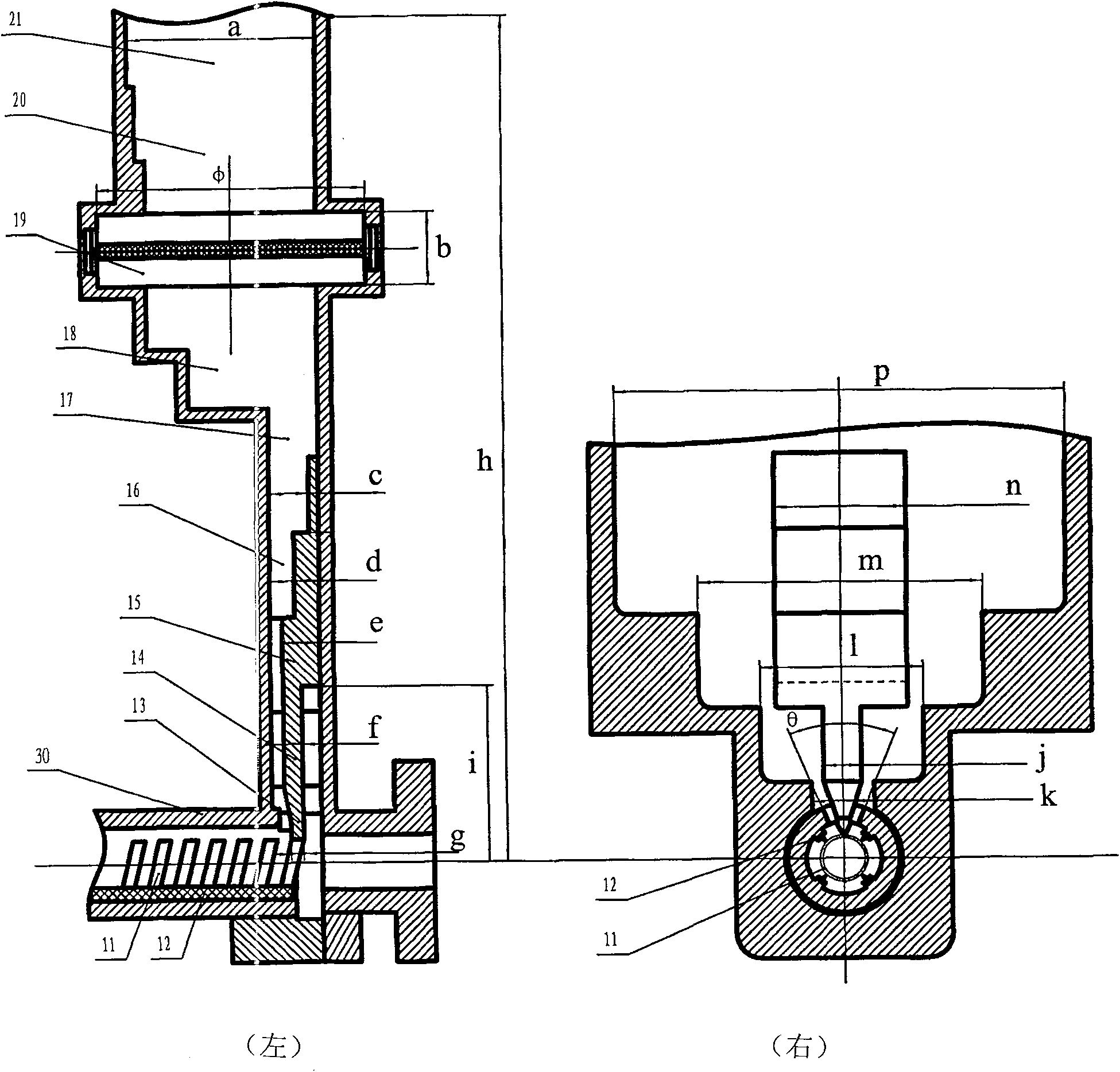

[0018] Technical points of the present invention:

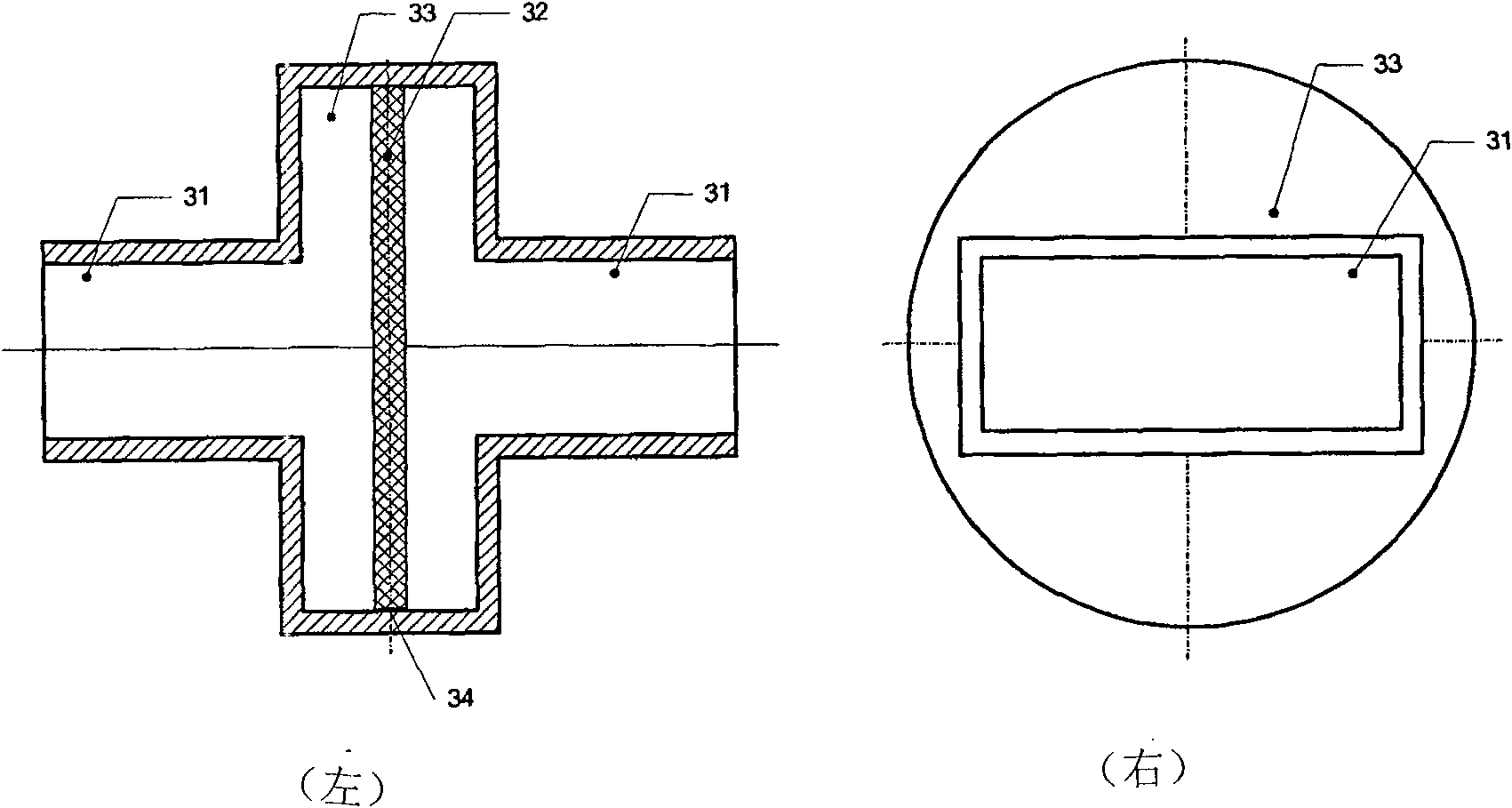

[0019] ① Local welding technology at the end of the helix uses four trapezoidal beryllium oxide ceramic clamping rods (generally three) to clamp the helix. The inner side of the clamping rod with the most serious heat generation is welded with the helical copper strip, and the outer side is welded with the oxygen-free copper outer conductor shell cooled by water, which realizes good thermal contact and improves the heat dissipation performance.

[0020] ② A transition structure composed of special-shaped metal strips and deformed waveguide walls is designed. This structure ensures the mode conversion and impedance matching from the helix to the standard waveguide within the full waveguide bandwidth. The standing wave coefficient is 1.26, and the helix The direct metal welding connection between the output end and the tube wall ensures good heat dissipation performance, making the microwave performance and heat dissipation per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com