Double covered optical fiber side-pumping coupler grating and realization method thereof

A double-clad fiber, side-pumped technology, applied in the direction of clad fiber, multi-layer core/clad fiber, optical waveguide coupling, etc., can solve the problems of high implementation cost, complex process, low coupling efficiency, etc. Achieve the effect of economical processing cost, simple process and high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

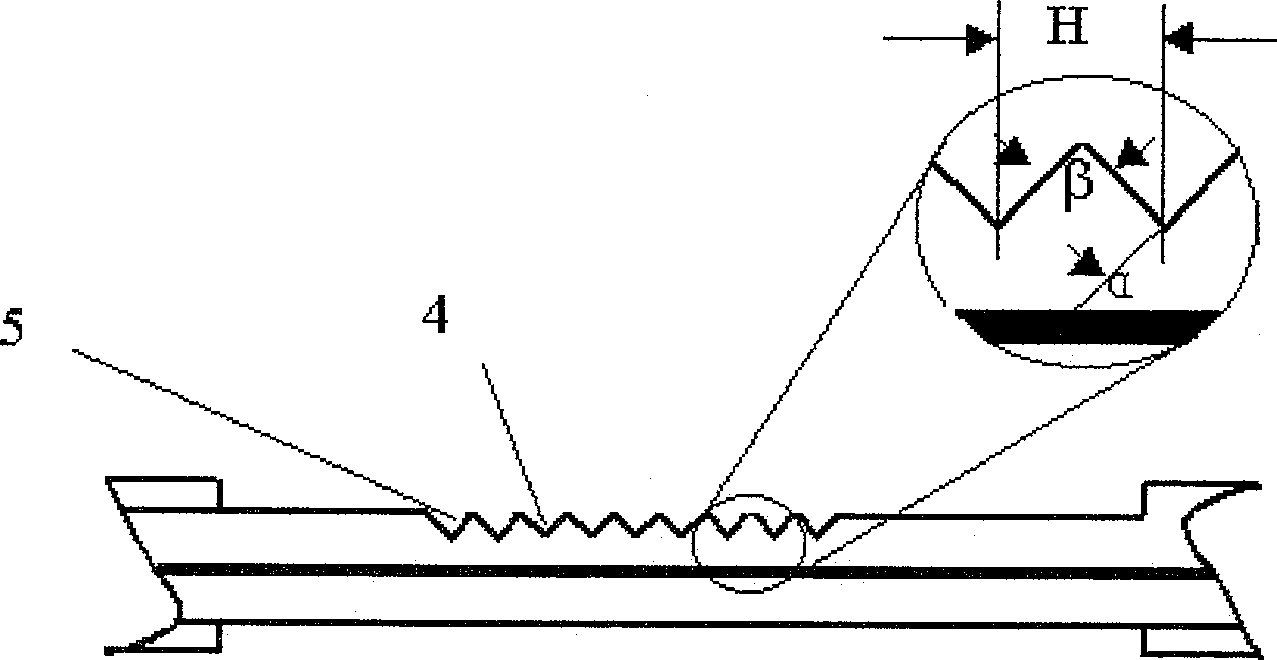

[0029] A laser diode array double-clad fiber side-pumped coupled volume grating, the cross-section along the axis is as follows image 3 shown. On the surface of the rectangular inner cladding 2 of the double-clad optical fiber, in the direction perpendicular to the double-clad optical fiber, there is a group of parallel and closely arranged isosceles triangular transverse grooves 4 with the same structure, and the slope surface of the isosceles triangular transverse groove 4 Angle α is not less than , the width H of the isosceles triangular transverse groove 4 is equal to

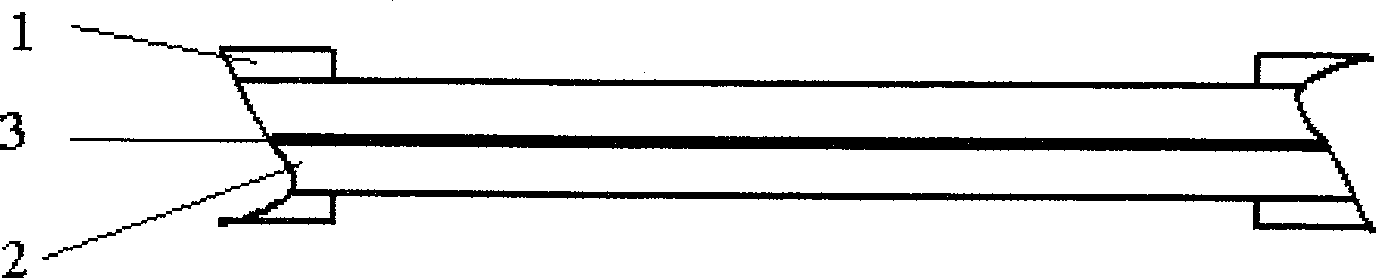

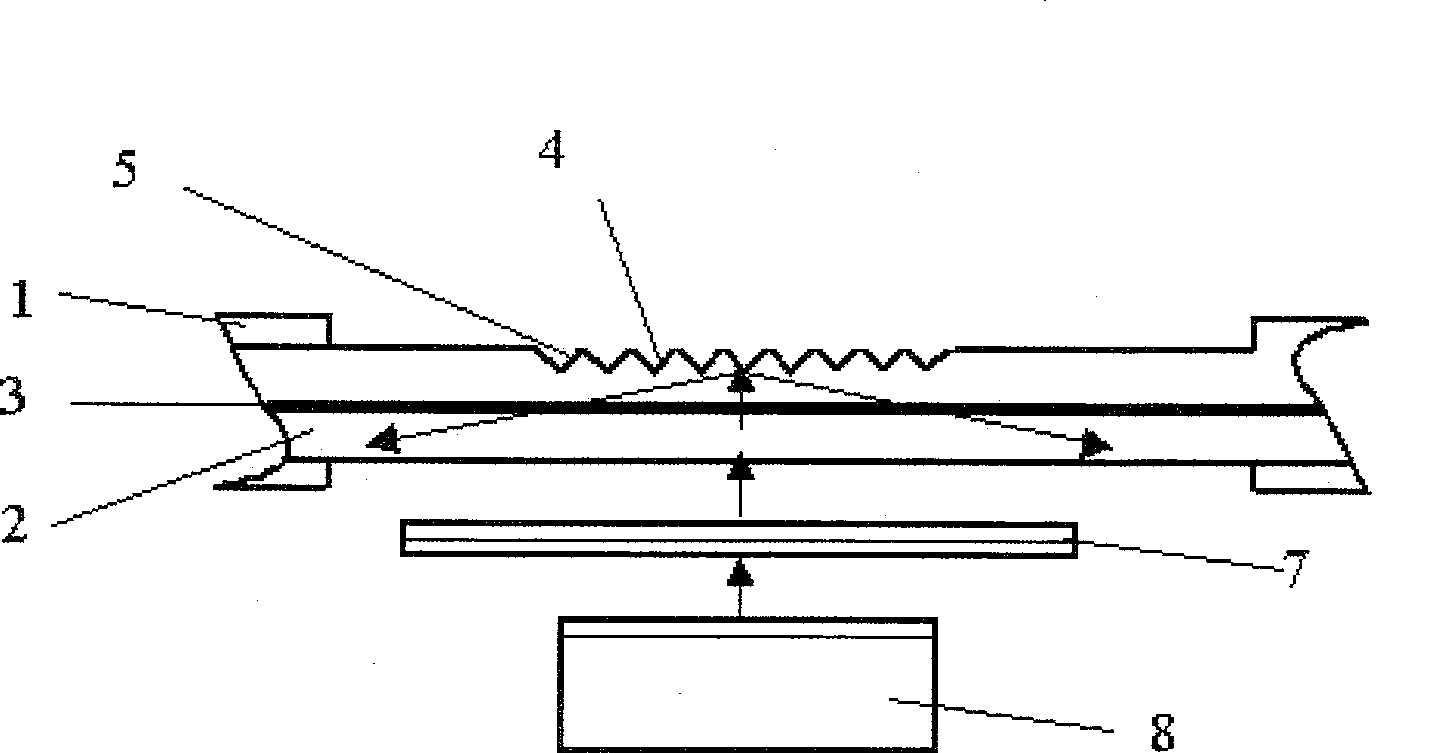

[0030] The double-clad doped fiber uses a polymer outer cladding, and the refractive index of the material of the polymer outer cladding 1 is n 3 is 1.37, the refractive index n of the rectangular inner cladding 2 material 2 is 1.444, the refractive index n of the core 3 material 1 is 1.45, and the pump laser wavelength λ is 975 nm. Such as figure 1 , 2 , 3, the laser diode array double-clad fibe...

Embodiment 2

[0035] A laser diode array microstructure double-clad fiber side-pumped dielectric film coupled volume grating, the cross-section along the axis is as follows Figure 5 shown. On the surface of the D-shaped inner cladding 2 of the microstructured double-clad optical fiber, in the direction perpendicular to the double-clad optical fiber, there is a group of parallel and closely arranged isosceles triangular transverse grooves 4 with the same structure, and the isosceles triangular transverse grooves 4 slope angle α is not less than , the width H of the isosceles triangular transverse groove 4 is equal to λ n 2 sin 2 α .

[0036] The realization of a laser diode array microstructure double-clad fiber side-pumped dielectric film-coupled volume grating, such as figure 1 , 2 , 3, and 4 show that the double-clad doped fiber adopts...

Embodiment 3

[0041] A multiple laser diode array double-clad fiber side-pumped coupled volume grating group, the cross-section along the axis is as follows Figure 8 shown. On the surface of the octagonal inner cladding 2 of the double-clad optical fiber, in the direction perpendicular to the double-clad optical fiber, there are multiple sets of parallel and closely arranged isosceles triangular transverse grooves 4 with the same structure, and isosceles triangular transverse grooves 4 The slope angle α is not less than , the width H of the isosceles triangular transverse groove 4 is equal to . This coupling structure can be used to make fiber lasers and amplifiers of thousands of watts or even 10,000 watts. Such as Figure 6 , 7 , 8 shown.

[0042] The implementation of the multiple laser diode array double-clad fiber side-pumped coupled bulk grating group, such as Figure 6 , 7 , 8, the refractive index n of the polymer outer cladding 3 material of the quartz double-clad doped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com