Spacer flange for a machine tool

An intermediate flange and machine tool technology, applied in the field of intermediate flanges, can solve the problems of expensive structure and heavy weight, and achieve the effect of reducing material input, reducing weight, and high torsional rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

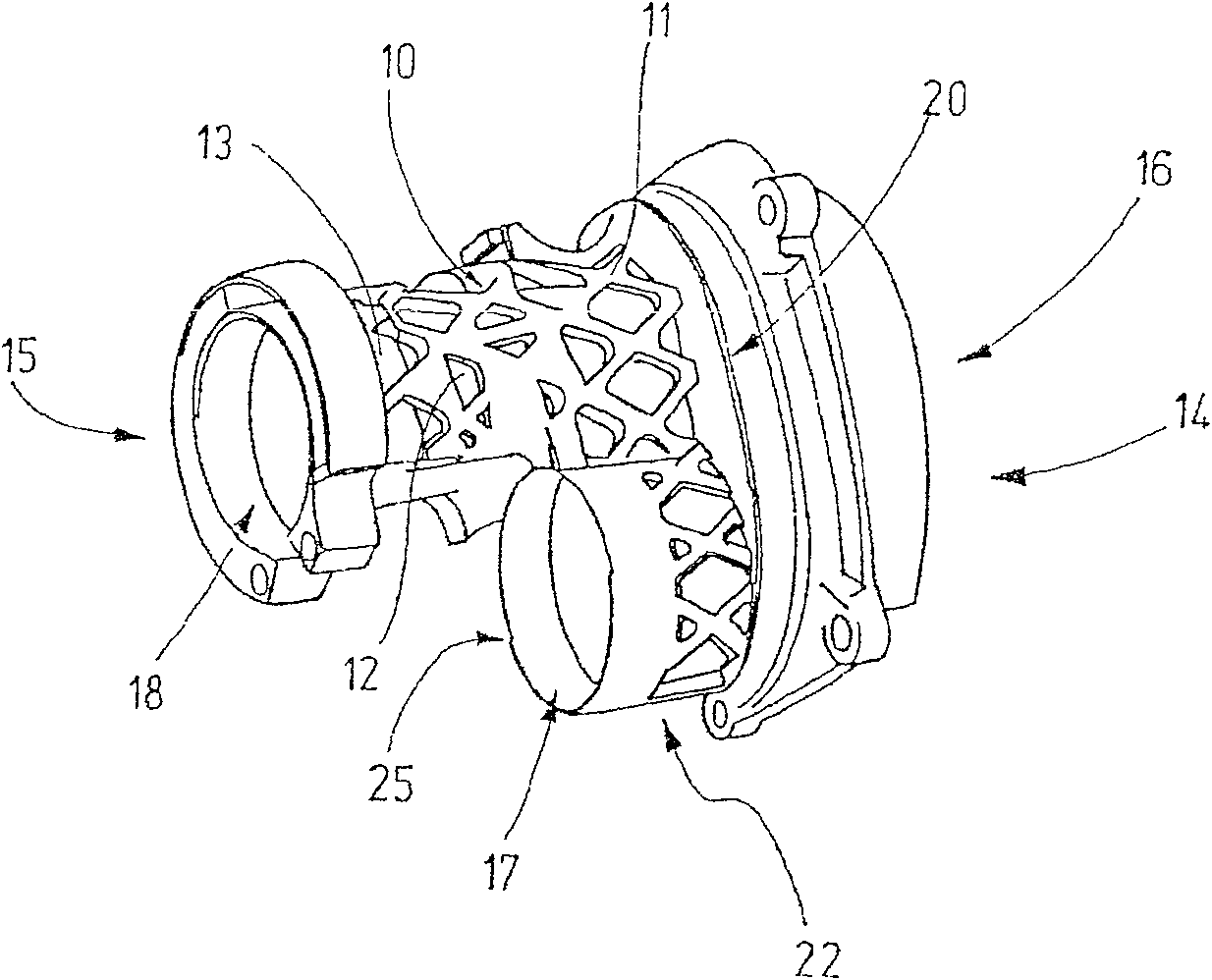

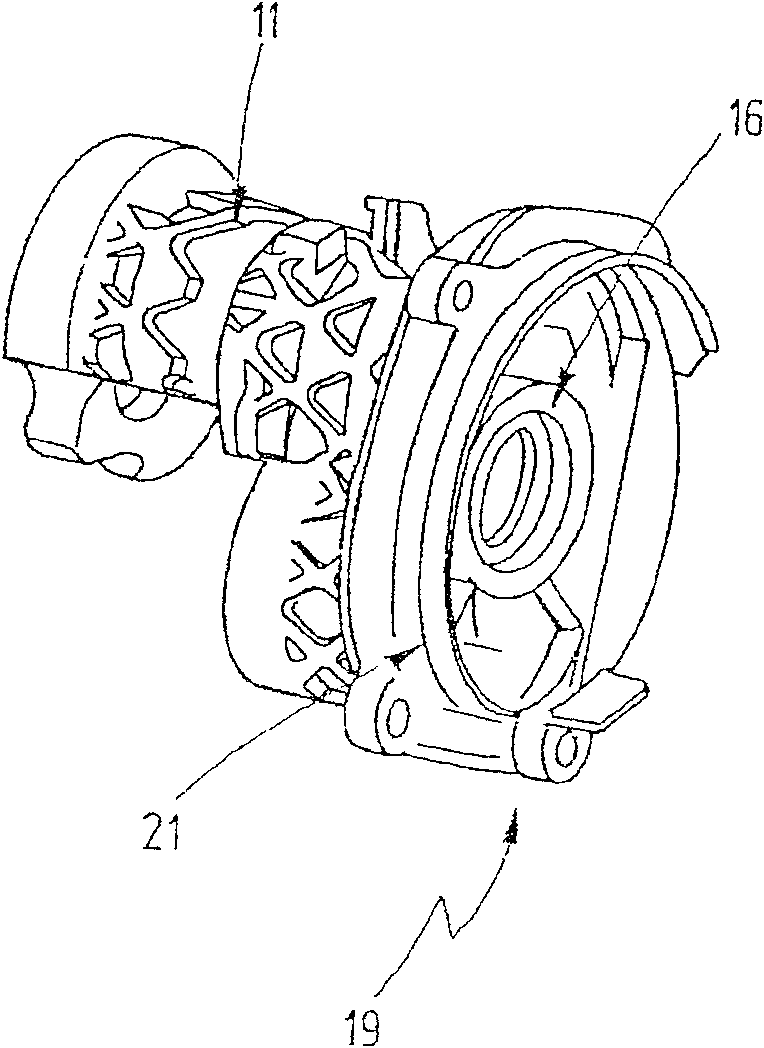

[0014] figure 1 Shows a perspective view of an embodiment of an intermediate flange according to the invention for a power tool, which is arranged in a housing (not shown) in the mounted state, in addition, in the housing There is also a drive motor (not shown), in particular an electric motor, a transmission and an impact device. The intermediate flange has an outer wall 22 with a grid-like support structure 10 having a regular, rhomboid structure. The support structure 10 is formed by solid webs 11 which intersect one another. Regions 12 located between webs 11 of the structure are filled with material, wherein these regions 12 of filling material are configured thinner-walled than webs 11 . For the sake of simplicity, only one of the webs 11 and one of the regions 12 is provided with reference numerals. Between the regions 12 of the filler material and the individual webs 11 there are in each case formed hollow spaces 13 which are open to the outside, so that a surface s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com