Process and equipment for the production of packaging material for electronic component cases

A technology for packaging materials and electronic components, which is applied in the field of manufacturing of packaging materials for electronic component casings and manufacturing equipment, can solve problems such as increased manufacturing costs, and achieve the effect of preventing air residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] (false bonding process)

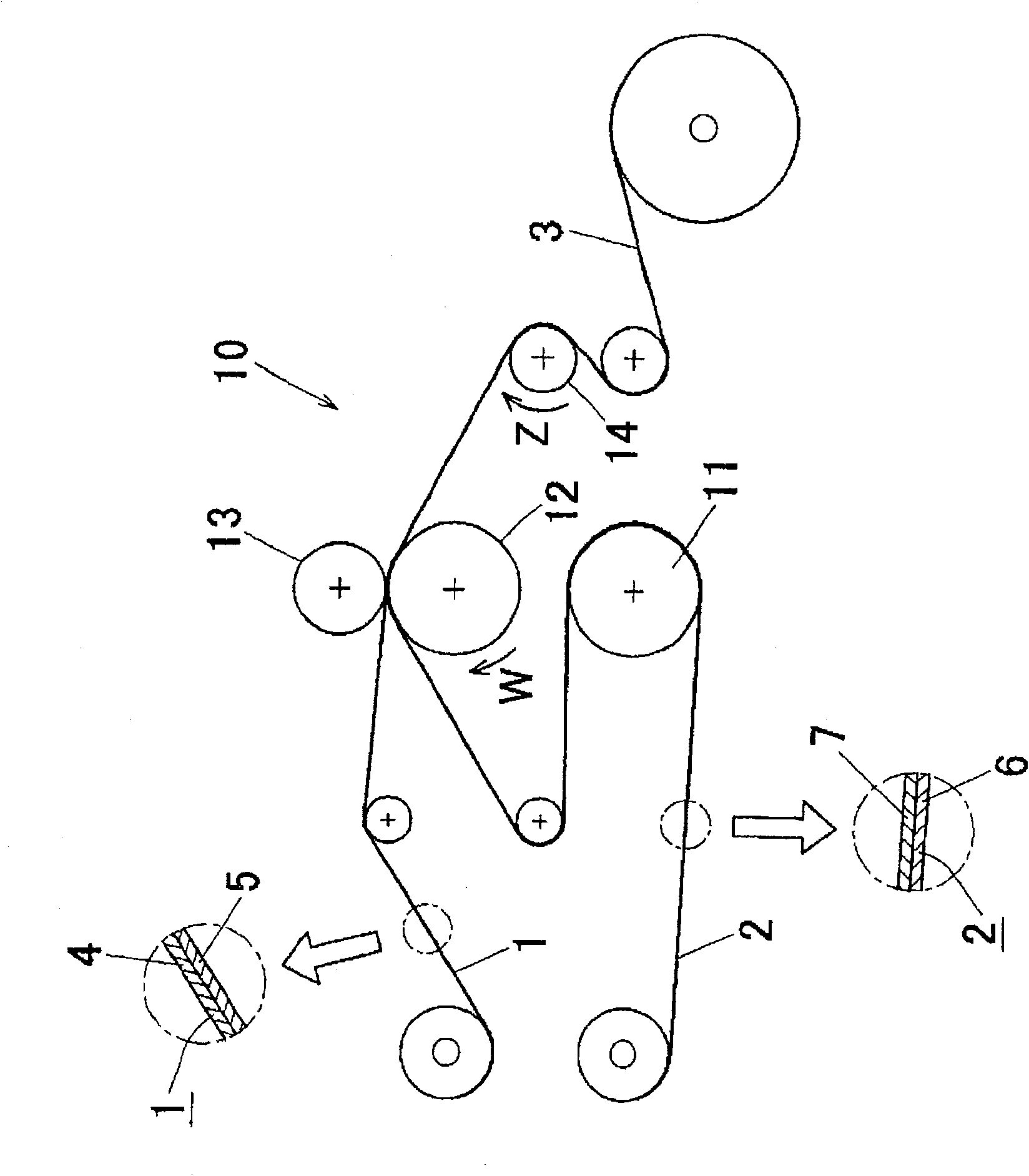

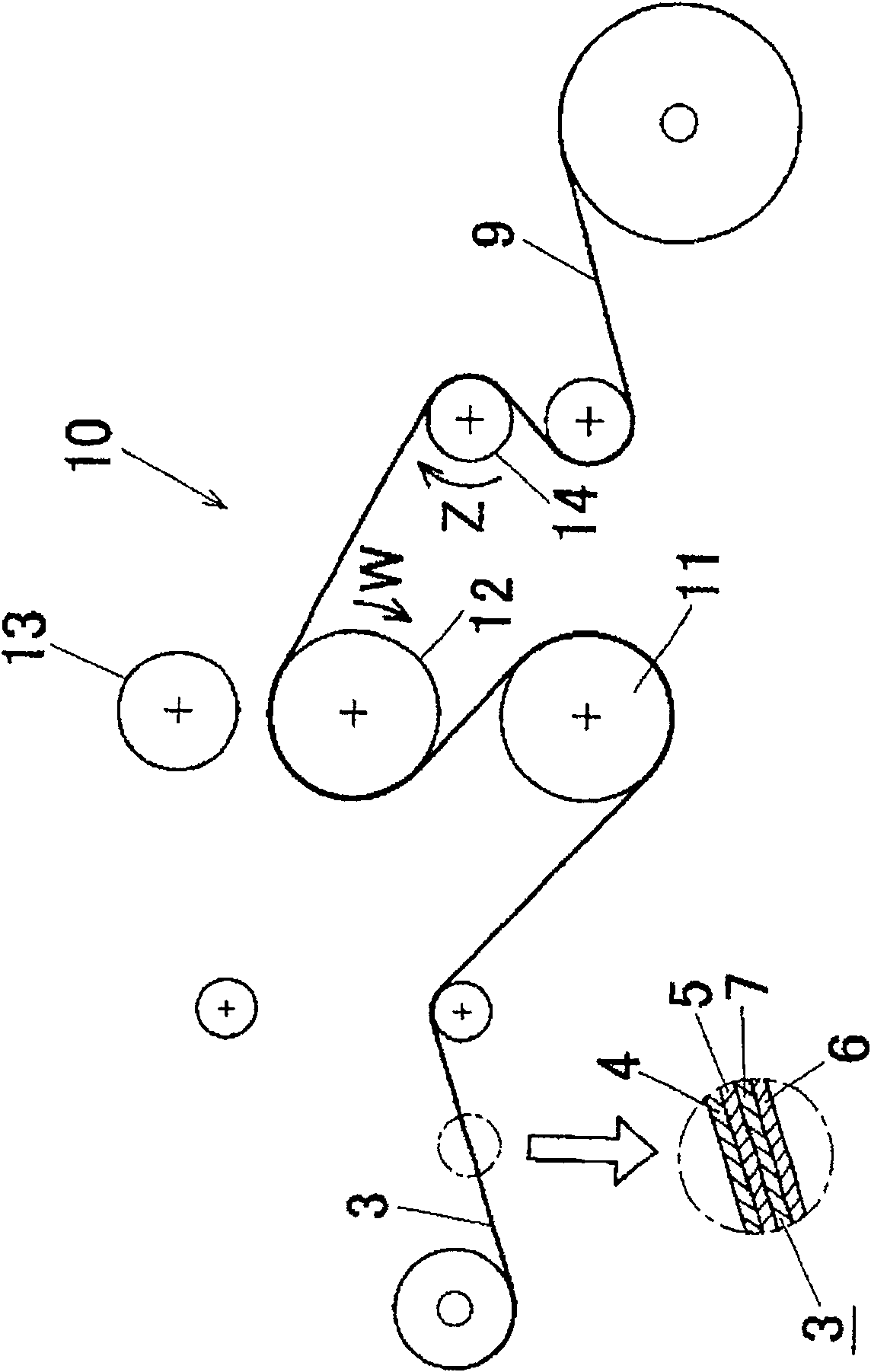

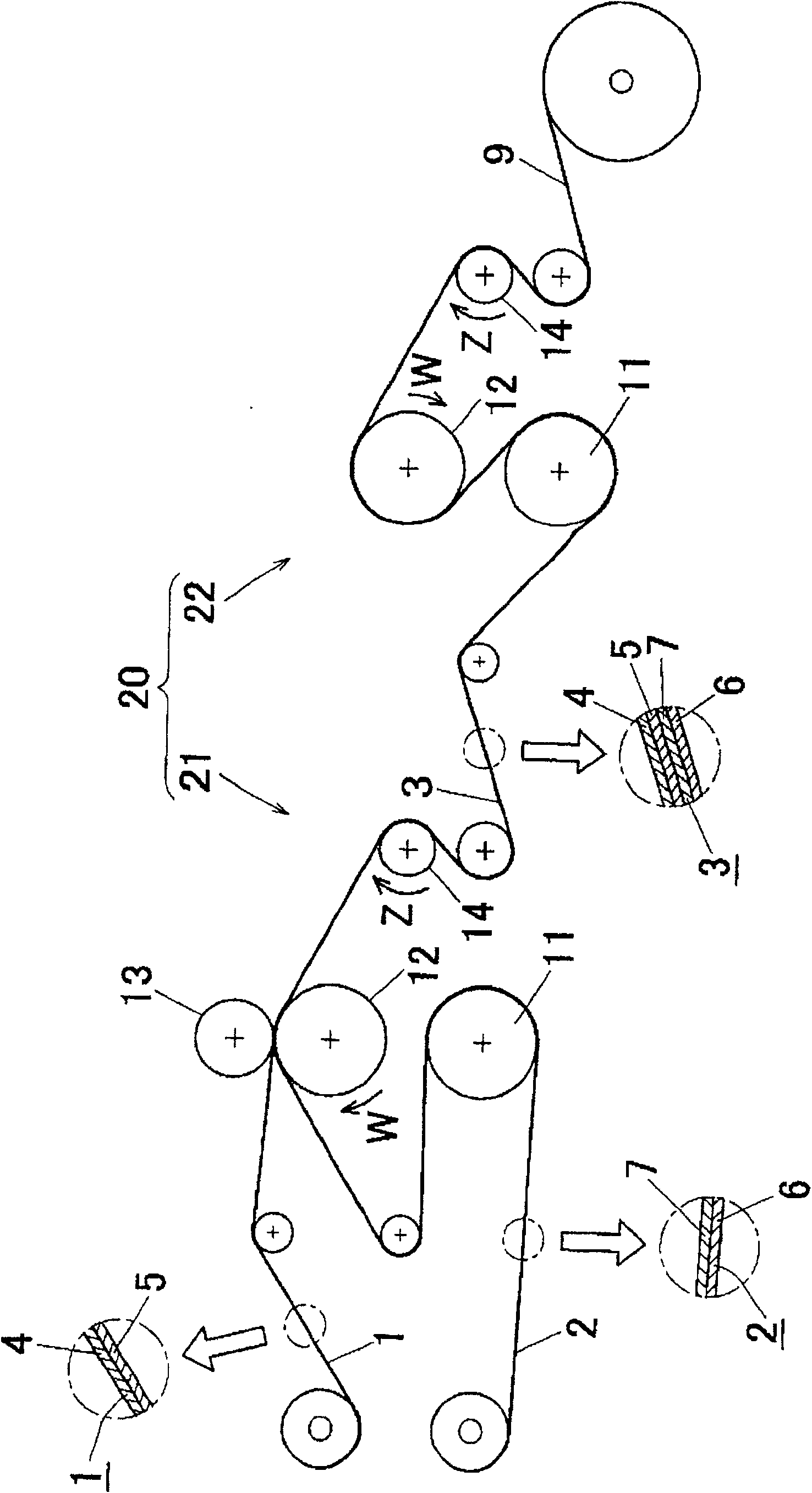

[0081] The first layer formed by laminating a maleic anhydride-modified polypropylene film (thermoplastic adhesive resin layer) (5) with a thickness of 15 μm on one side of a polypropylene film (thermoplastic resin unstretched film layer) (4) with a thickness of 35 μm. A sheet (1), and a second sheet (2) formed by laminating an aluminum foil (7) with a thickness of 40 μm on one side of a polyamide film (heat-resistant resin stretched film layer) (6) with a thickness of 25 μm, and The form of contact between maleic anhydride modified polypropylene film (5) and aluminum foil (7), in figure 1 The manufacturing device (10) shown passes between the heating roller (12) and the rubber roller (13) for nip pressing and false bonding, followed by the cooling roller (14) for slow cooling to obtain a pre-laminated sheet (3), and wind it up.

[0082] In the above-mentioned false bonding process, the temperature of the preheating roll (11) is set at 70°C, ...

Embodiment 2

[0087] In the dummy bonding process, the packaging material for electronic component cases was produced in the same manner as in Example 1 except that the temperature of the heating roll was set at 150°C and the temperature of the cooling roll was set at 90°C.

Embodiment 3、4

[0089] Except having set the conditions shown in Table 1, it carried out similarly to Example 1, and manufactured the packaging material for electronic component cases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com