Oil-in-water type emulsion composition and method for production thereof

An oil-in-water type and composition technology, which is applied in chemical instruments and methods, pharmaceutical formulations, transportation and packaging, etc., can solve problems such as products that are difficult to use widely, and achieve the effects of inhibiting the increase in viscosity over time and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

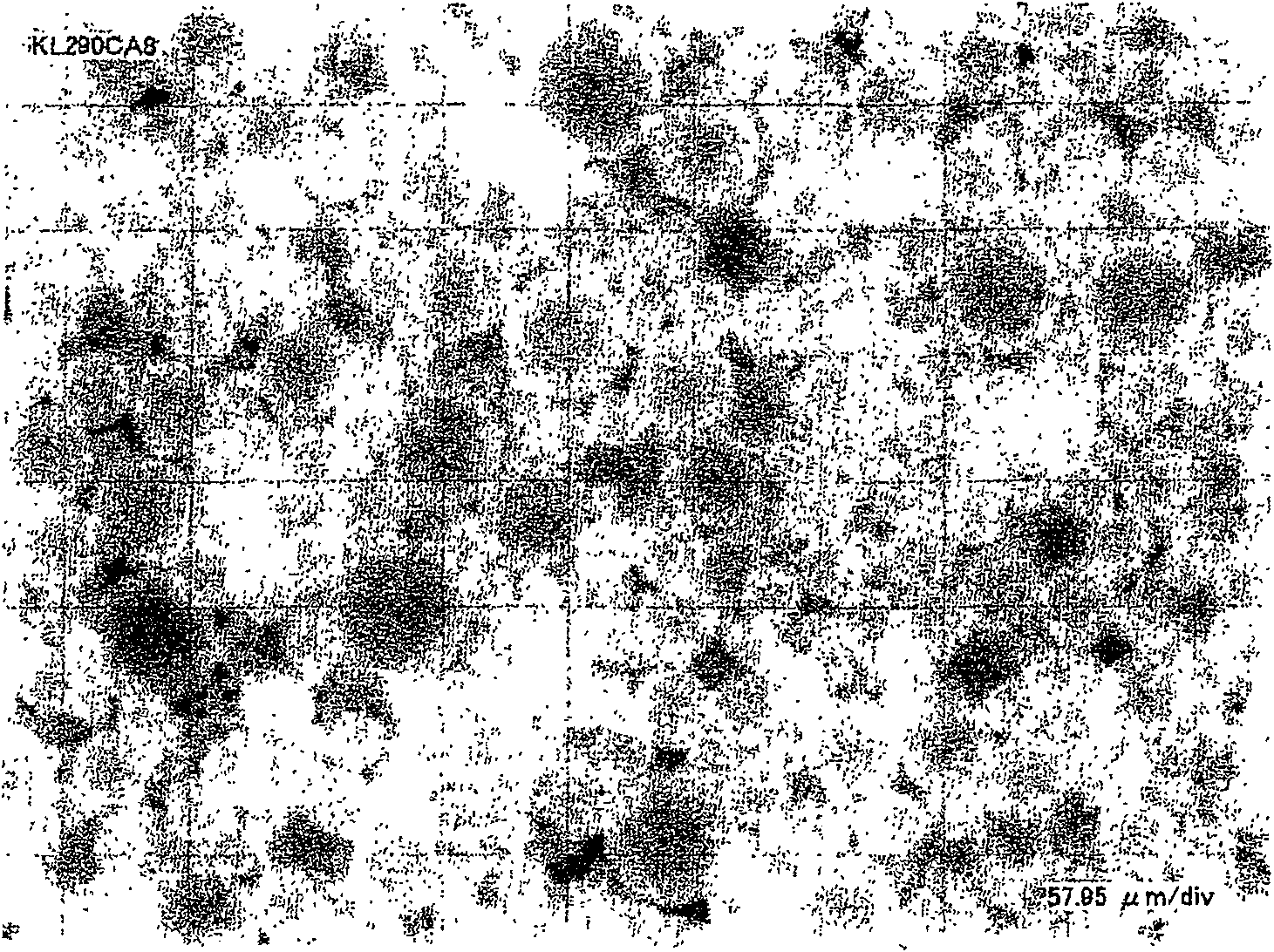

Image

Examples

Embodiment 1

[0043] 22.5 parts by weight of an aliphatic alcohol with 18 carbon atoms [SASOL Corporation, Nacol 18-98] and 7.5 parts by weight of calcium carbonate as poorly water-soluble hydrophilic inorganic particles [Shiraishi Industry Co., Ltd., Brilliant-1500] , Heat and melt aliphatic alcohols with 18 carbon atoms. Then, the molten material was stirred at 73°C with a turbine blade at a peripheral speed of 5.2 m / s, while hot water at 73°C was dropped. When it becomes a highly viscous gel-like mixture, the stirring is temporarily stopped, and then 69.94 parts by weight of hot water at 73° C. is added in total, and then the stirring is restarted. To the resulting emulsified dispersion liquid was added 0.06 parts by weight of Eylan Gem (product name) (Sanjing Co., Ltd., KIC376), and cooled to obtain an oil-in-water emulsion composition. The results of the time-lapse thickening test of the sample composition of Example 1 are shown in "Table 1" below.

[0044] [Table 1]

[0045] [Example 1:...

Embodiment 2

[0049] A mixture of 22.5 parts by weight of aliphatic alcohol with 18 carbon atoms [SASOL Corporation, Nacol 18-98] and poorly water-soluble hydrophilic inorganic fine particles of aluminum hydroxide [Kanto Chemical Co., Ltd. Deer Special Grade Average particle size 0.05μm ] 7.5 parts by weight, using the same method as in Example 1 below, a sample of an oil-in-water emulsion composition was obtained. The results of the thickening test with time for the sample composition of Example 2 are shown in "Table 2" below.

[0050] [Table 2]

[0051] [Example 2: Results of a thickening test with time]

[0052] Measurement conditions

[0053] As shown in the above "Table 3", the viscosity of this sample was 352 mPa·s immediately after manufacture, and after storage at 10°C, 20°C, 30°C, and 40°C for 30 days, they were 370, 403, 410, and 425 mPa·s, respectively. s. That is, almost no change in viscosity over time occurs.

Embodiment 3

[0055] A mixture of 22.5 parts by weight of aliphatic alcohol with 18 carbon atoms [SASOL Corporation, Nacol 18-98] and alumina (Kanto Chemical Co., Ltd. Deer Special Grade) as poorly water-soluble hydrophilic inorganic particles, and 7.5 parts by weight, below In the same manner as in Example 1, a sample of an oil-in-water emulsion composition was obtained. The results of the thickening test with time for the sample composition of Example 3 are shown in the following "Table 3".

[0056] [table 3]

[0057] [Example 3: Results of a thickening test with time]

[0058] Measurement conditions

[0059] As shown in the above "Table 3", the viscosity of this sample was 412 mPa·s immediately after manufacture, and after storage at 10°C, 20°C, 30°C, and 40°C for 30 days, they were 455, 461, 466, and 503 mPa·s, respectively. s. That is, almost no change in viscosity over time occurs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com