Heat pipe steamer and its control method

A technology of heat pipe type and steamer, which is applied in heat storage heaters, fluid heaters, steam cooking utensils, etc. It can solve the problems of increasing the internal pressure of the steamer and cannot completely eliminate the discharge of steam, so as to improve the problem of steam diffused and easy Use and maintenance, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

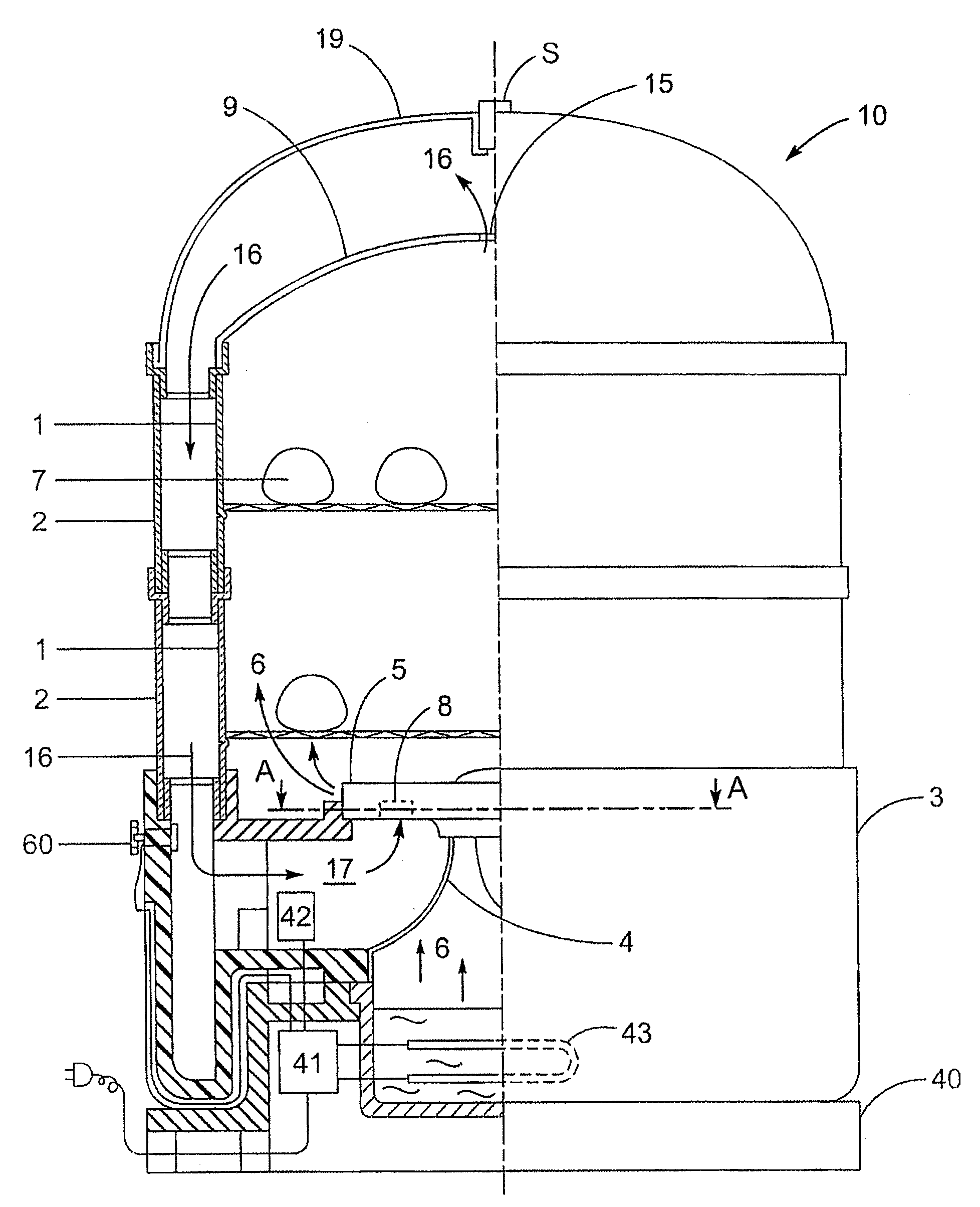

[0039] figure 1 It is an explanatory diagram of the previous energy-saving and water-saving steamer, which is an energy-saving and water-saving steamer technical solution proposed by the inventor. The steam 6 generated by the steam generator 40 enters the steam injection base 3, and the steam 6 passes through the steam nozzle 4 of the steam injection base 3 Injected into the steamer body 1, the convective force makes the steam 6 rise from the bottom of the steamer body 1 to heat the food 7; the recovered water vapor 16 escapes from the air hole 15 on the inner cover 9 by convection at the top of the steamer body 1, and enters the steam recovery device 2. The steam recovery device 2 cools and sinks the recovered steam 16, guides the steam injection base 3, and the Venturi effect ejector 5 in the steam injection base 3 utilizes the Venturi effect produced when the steam accelerates through, so that the recovered steam 16 is Introduce into the bottom of the steamer body 1 and ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com