Composite sulfur enveloped slow release fertilizer

A slow-release fertilizer and sulfur-coated technology, which is applied in the field of coated slow-release fertilizers and compound sulfur-coated slow-release fertilizers, can solve the problems of long release period, limited application fields, and high price of coated slow-release urea , to achieve the effect of stable release period and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

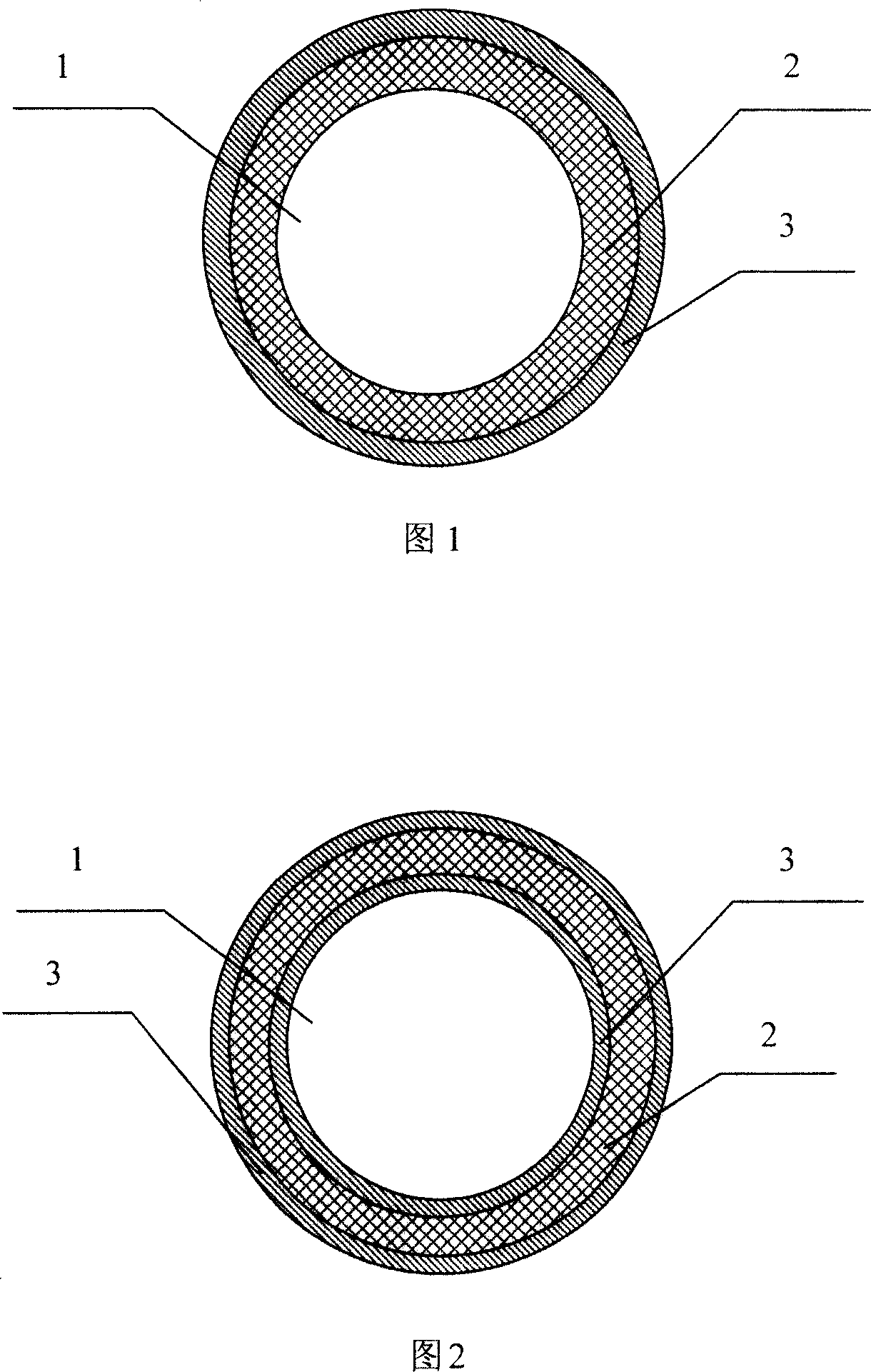

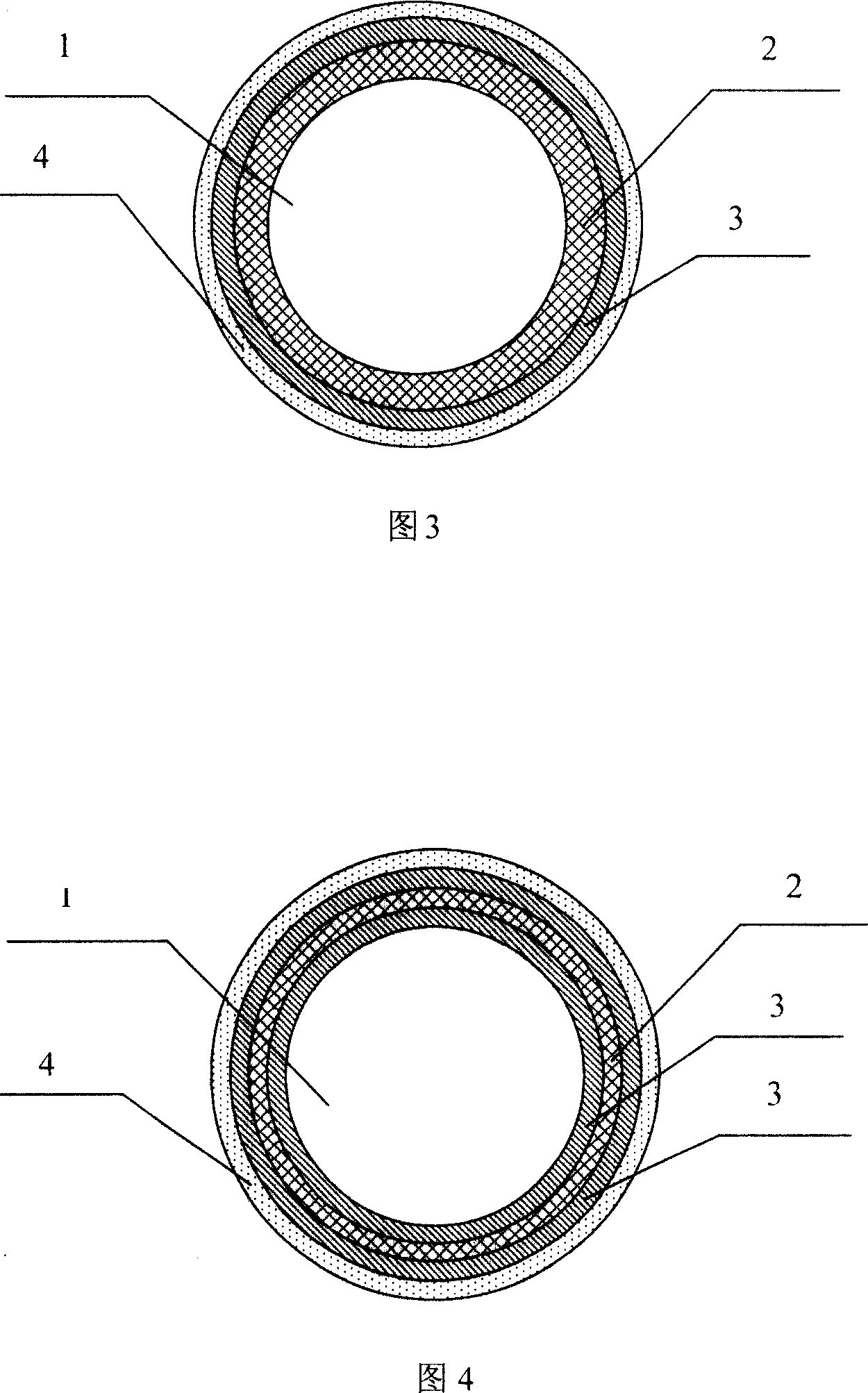

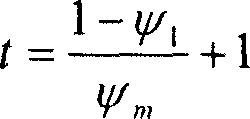

Embodiment 1

[0037] The granular industrial urea with a particle size of 2.0-4.0mm is added to the fluidized bed coating equipment, and the granular urea is in a boiling state, and the temperature of the granular urea in the fluidized bed is maintained at 85°C. Slowly spray molten sulfur at about 150°C on the surface of the granular urea, and spray until the quality of the formed sulfur film reaches 10% of the total mass of the final product composite sulfur-coated slow-release urea. Then, the mixture of 4,4-diphenylmethane diisocyanate MDI, triethanolamine and diethylene glycol (the molar ratio of triethanolamine: diethylene glycol is 0.2:1, and the molar ratio of -NCO:-OH is 1.1:1 ) The melt and the molten sulfur at about 150°C were sprayed slowly on the surface of the sulfur film from two different nozzles at the same time. By controlling their spraying flow ratio, the average mass of sulfur in the sulfur-containing polyurethane mixture film formed by spraying The fraction is 60%, and the m...

Embodiment 2

[0039] The granular industrial urea with a particle size of 2.0-4.0mm is added to the fluidized bed coating equipment, and the granular urea is in a boiling state, and the temperature of the granular urea in the fluidized bed is maintained at 85°C. Slowly spray molten sulfur at about 150°C on the surface of the granular urea, and spray until the quality of the formed sulfur film reaches 15% of the total mass of the final product composite sulfur-coated slow-release urea. Then, the mixture of 4,4-diphenylmethane diisocyanate MDI, polypropylene glycol (average molecular weight of 2000) and butylene glycol (polypropylene glycol: butylene glycol mass ratio 1:0.1, -NCO: -OH The molar ratio is 1.1:1) The melt and the molten sulfur at about 150°C are sprayed slowly on the surface of the sulfur film from two different nozzles at the same time; control their spraying flow ratio, the spraying flow of molten sulfur is the largest at the beginning, It gradually decreases to zero at the end, w...

Embodiment 3

[0041] Add granular industrial urea with a particle size of 2.0-4.0mm into a drum coating equipment with a temperature controlled at 95°C, and rotate the drum (rotational speed 40r / min) to make granular urea flow in the drum. Slowly spray molten sulfur at about 150°C on the surface of the granular urea, and spray until the quality of the formed sulfur film reaches 8% of the total mass of the final product composite sulfur-coated slow-release urea. Then, melt the mixture of CYD-115 epoxy resin prepolymer plasticized by dibutyl phthalate and mixed amine curing agent (the mass fraction of dibutyl phthalate is 15%) at 150°C The left and right molten sulfur are sprayed slowly on the surface of the sulfur film from two different nozzles at the same time; control their spraying flow ratio, the spraying flow of molten sulfur is the largest at the beginning, and gradually decreases to zero at the end, while CYD-115 The spray flow rate of the mixture melt of epoxy resin prepolymer and mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com