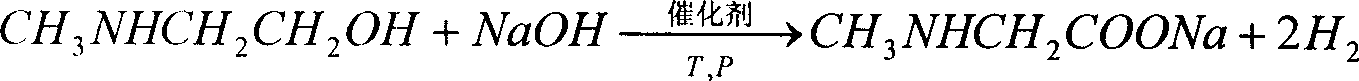

Method for synthesizing natrium sarkosine from methyl - ethanolamine

A technology of methyl monoethanolamine and sodium sarcosinate, which is applied in the field of synthesis of daily chemical raw materials, can solve the problems of low product quality, high production cost, and many "three wastes" pollution, and achieve the effect of simple post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 100 parts by weight of methyl monoethanolamine and 150 parts by weight of deionized water are dropped into a high-pressure stainless steel reactor, 30% liquid caustic soda of 100 parts by weight is added, and the skeleton copper catalyst of trace metal modification of 5 parts by weight is added, at 140 ℃, 0.6MPa pressure, react for 8 hours, there will be H during the reaction 2 Generated, enter H through decompression, scrubbing, drying and other processes 2 storage tank. H generated by metering 2 Quantity, to judge the degree of conversion of methyl ethanolamine, to determine the termination of the reaction. Cool down to about 50°C, then release residual H 2 .

[0028] The crude product was left overnight. Suck out the upper layer liquid, and then filter out a small amount of catalyst particles to obtain the product sodium sarcosinate (sodium methylglycinate).

Embodiment 2

[0030] 100 parts by weight of methyl monoethanolamine and 250 parts by weight of deionized water are dropped into a high-pressure stainless steel reactor, 30% liquid caustic soda of 150 parts by weight is added, and a trace metal-modified skeleton copper catalyst of 10 parts by weight is added, at 160 ℃, 1.0MPa pressure, react for 6 hours, there will be H during the reaction 2 Generated, enter H through decompression, scrubbing, drying and other processes 2 storage tank. H generated by metering 2 Quantity, to judge the degree of conversion of methyl ethanolamine, to determine the termination of the reaction. Cool down to about 50°C, then release residual H 2 .

[0031] The crude product was left overnight. Suck out the upper layer liquid, and then filter out a small amount of catalyst particles to obtain the product sodium sarcosinate (sodium methylglycinate).

Embodiment 3

[0033] 100 parts by weight of methyl monoethanolamine and 300 parts by weight of deionized water are dropped into a high-pressure stainless steel reactor, 30% liquid caustic soda of 200 parts by weight is added, and the skeleton copper catalyst of trace metal modification of 15 parts by weight is added, at 200 ℃, 1.5MPa pressure, react for 3 hours, there will be H during the reaction 2 Generated, enter H through decompression, scrubbing, drying and other processes 2 storage tank. H generated by metering 2 Quantity, to judge the degree of conversion of methyl ethanolamine, to determine the termination of the reaction. Cool down to about 50°C, then release residual H 2 .

[0034] The crude product was left overnight. Suck out the upper layer liquid, and then filter out a small amount of catalyst particles to obtain the product sodium sarcosinate (sodium methylglycinate).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com