Manufacturing method of semiconductor device

一种制造方法、半导体的技术,应用在曝光领域,能够解决抗蚀剂膜抗蚀图形劣化、易产生缺陷、相对移动轨迹残留等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

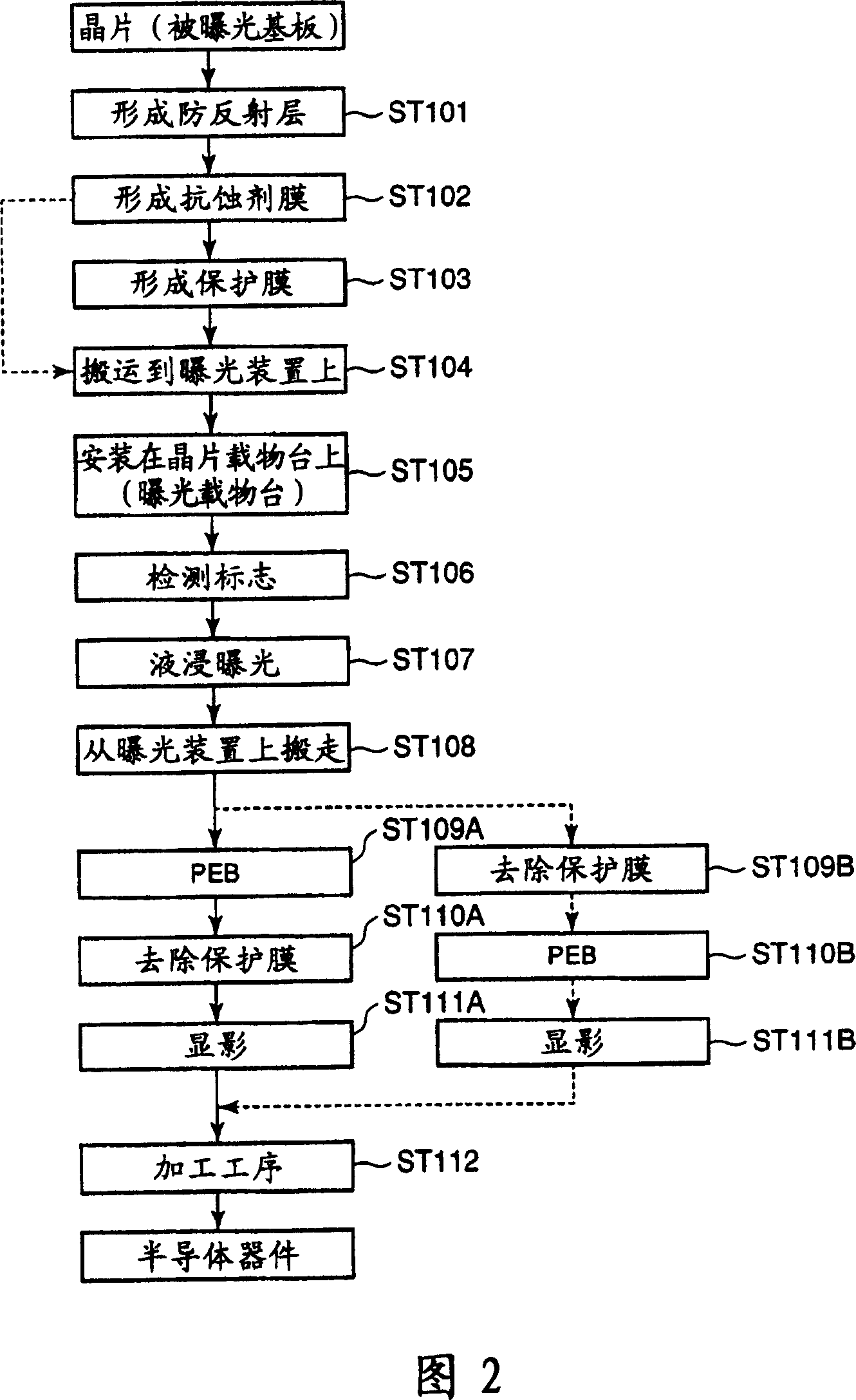

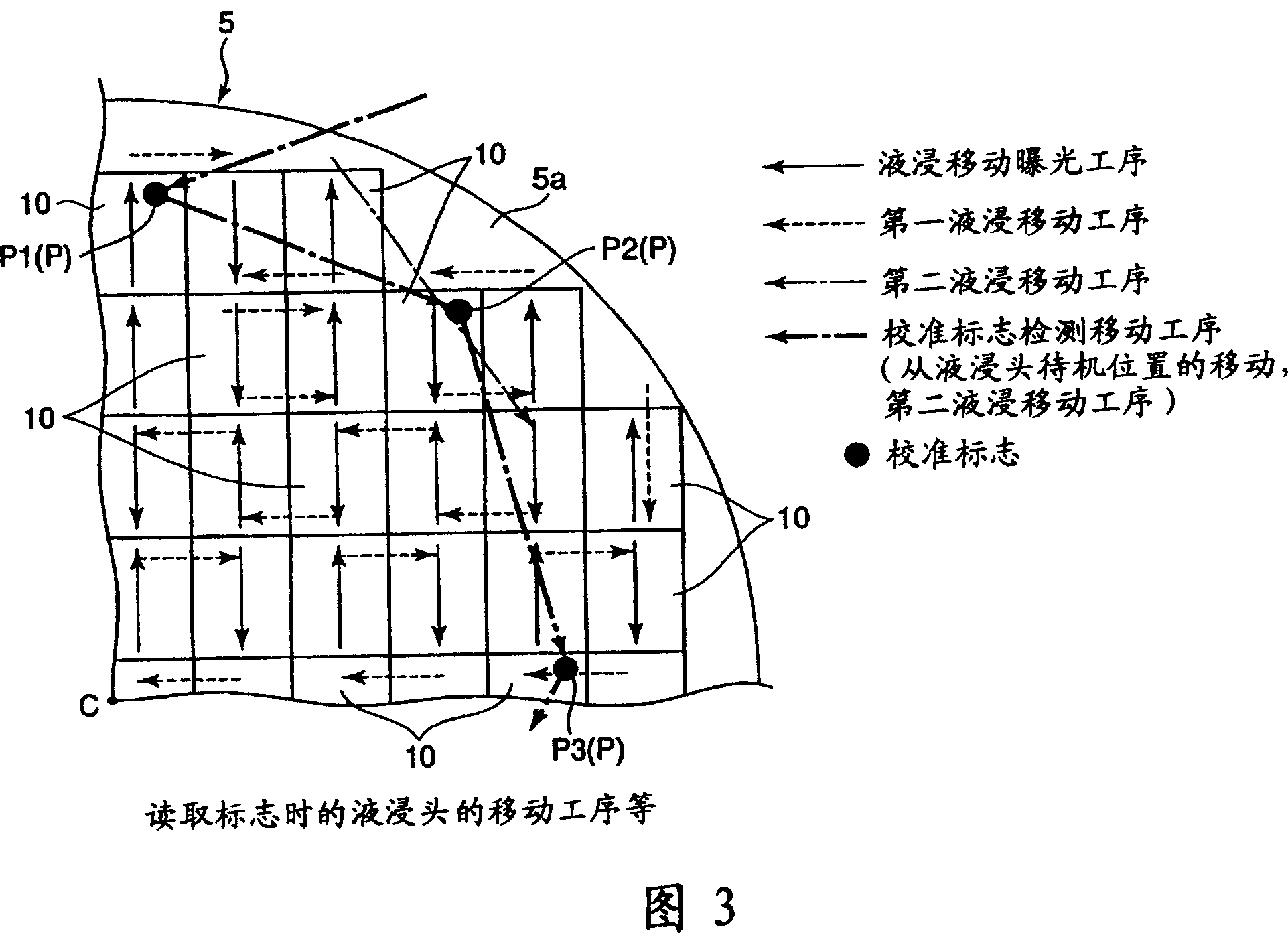

[0028] First, a first embodiment according to the present invention will be described with reference to FIGS. 1 to 11 . In this embodiment mode, a method for forming a resist pattern is described, which can suppress or reduce the possibility of defects in the resist pattern in a liquid immersion exposure technique in which a partial region on a substrate exposes a pattern through a liquid film. The specific description will be given below.

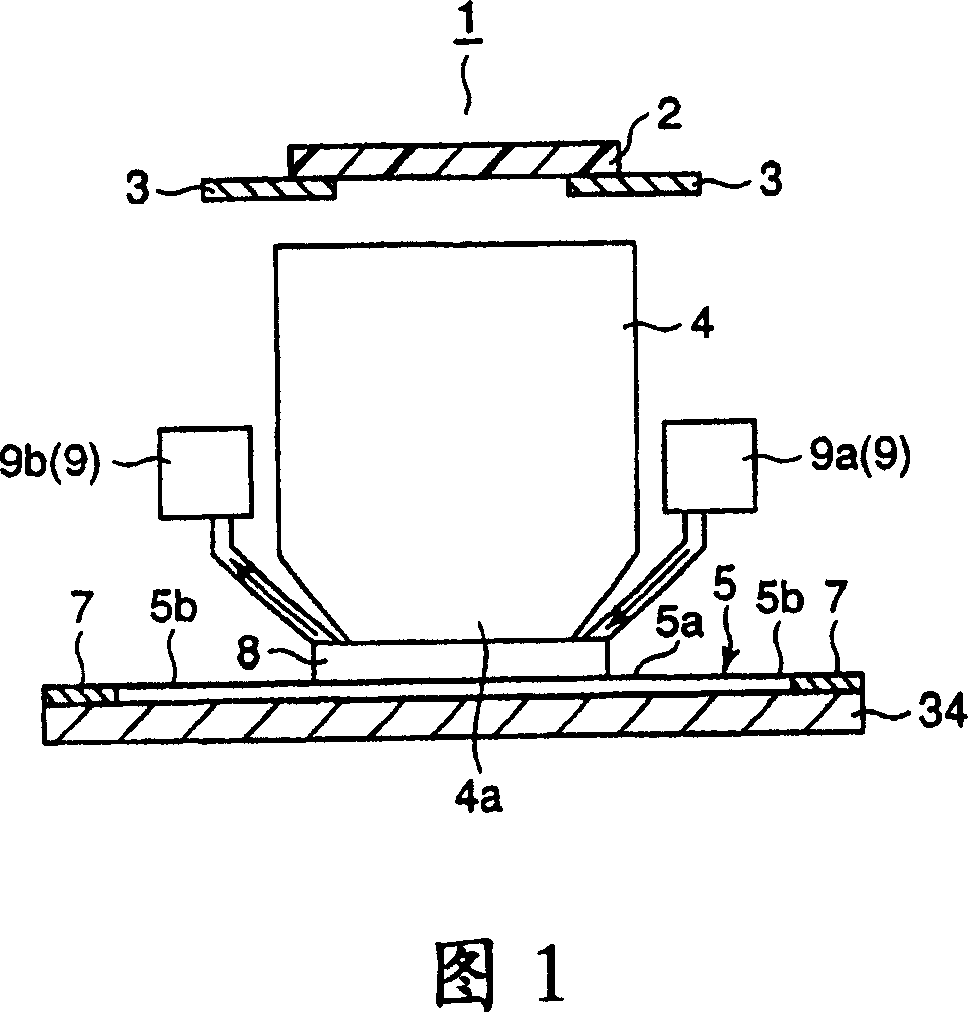

[0029] First, an exposure apparatus 1 according to the present invention will be described with reference to FIG. 1 . FIG. 1 is a schematic diagram showing a schematic configuration of an exposure apparatus 1 that performs exposure processing according to the present embodiment. The exposure apparatus 1 shown in FIG. 1 is a liquid immersion type exposure apparatus that performs so-called liquid immersion exposure, and performs exposure while a liquid is interposed between a substrate 5 to be exposed and the projection optical system 4 of ...

no. 2 Embodiment approach

[0097] Next, a second embodiment of the present invention will be described with reference to FIG. 12 . FIG. 12 is a plan view showing the relative movement trajectory of the liquid immersion head relative to the wafer in this embodiment according to each movement mode. In addition, the same code|symbol is attached|subjected to the same part as the said 1st Embodiment, and the detailed description is abbreviate|omitted.

[0098] In this embodiment, a technique for suppressing the generation of residual droplets by a method different from that of the first embodiment will be described. Specifically, in the second liquid immersion moving process, the longest moving distance in the same direction is calculated in consideration of the moving speed of the liquid immersion region 12 (stage 6), so that the liquid immersion region 12 (stage 6) is Zigzag movement is performed within the longest movement distance. Thereby, generation of residual liquid droplets is suppressed. A detai...

no. 3 Embodiment approach

[0104] Next, a third embodiment according to the present invention will be described with reference to FIG. 13 . FIG. 13 is a plan view showing the relative moving track of the liquid immersion head relative to the wafer in this embodiment according to each moving mode. In addition, the same code|symbol is attached|subjected to the same part as each of said 1st and 2nd embodiment, and the detailed description is abbreviate|omitted.

[0105] In the present embodiment, the liquid immersion area 12 not only passes through each exposure area 10 but also passes through the peripheral portion (outer edge portion, edge portion) 5b of the wafer 5 where the exposure area 10 is not set. In this case, it is also a technology that can suppress the generation of residual liquid droplets. Specifically, when the liquid immersion region 12 passes the edge portion 5 b of the wafer 5 , the relative moving speed of the liquid immersion region 12 with respect to the wafer 5 is decelerated. A de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com