Oxygen tailoring of polyethylene resins

A technology of polyethylene and polyethylene film, which is used in manufacturing tools, ceramic molding machines, ceramic molding workshops, etc., can solve problems such as improvement of optical properties that are not mentioned.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] Film thickness is measured according to ASTM D374-94 Method C.

[0055] Film thickness deviations were determined using a Measuretech Series 200 instrument. This instrument measures film thickness using a capacitance thickness gauge. For each film sample, ten film thickness points are measured per inch of film as the film passes the thickness gauge in the transverse direction. Three film samples were used to determine the thickness deviation. Thickness variation is determined by dividing the entire range of film thicknesses (maximum minus minimum) by the average thickness and dividing the result by two. Thickness deviation is expressed as a percent change from the mean.

[0056] Dart impact values were determined using the procedure in ASTM D1709-98 Method A, except that film thickness was measured according to ASTM D374-94 Method C.

[0057] Elmendorf tear strength (machine direction, "MD"; and transverse direction, "TD") was determined using the procedure in A...

Embodiment A

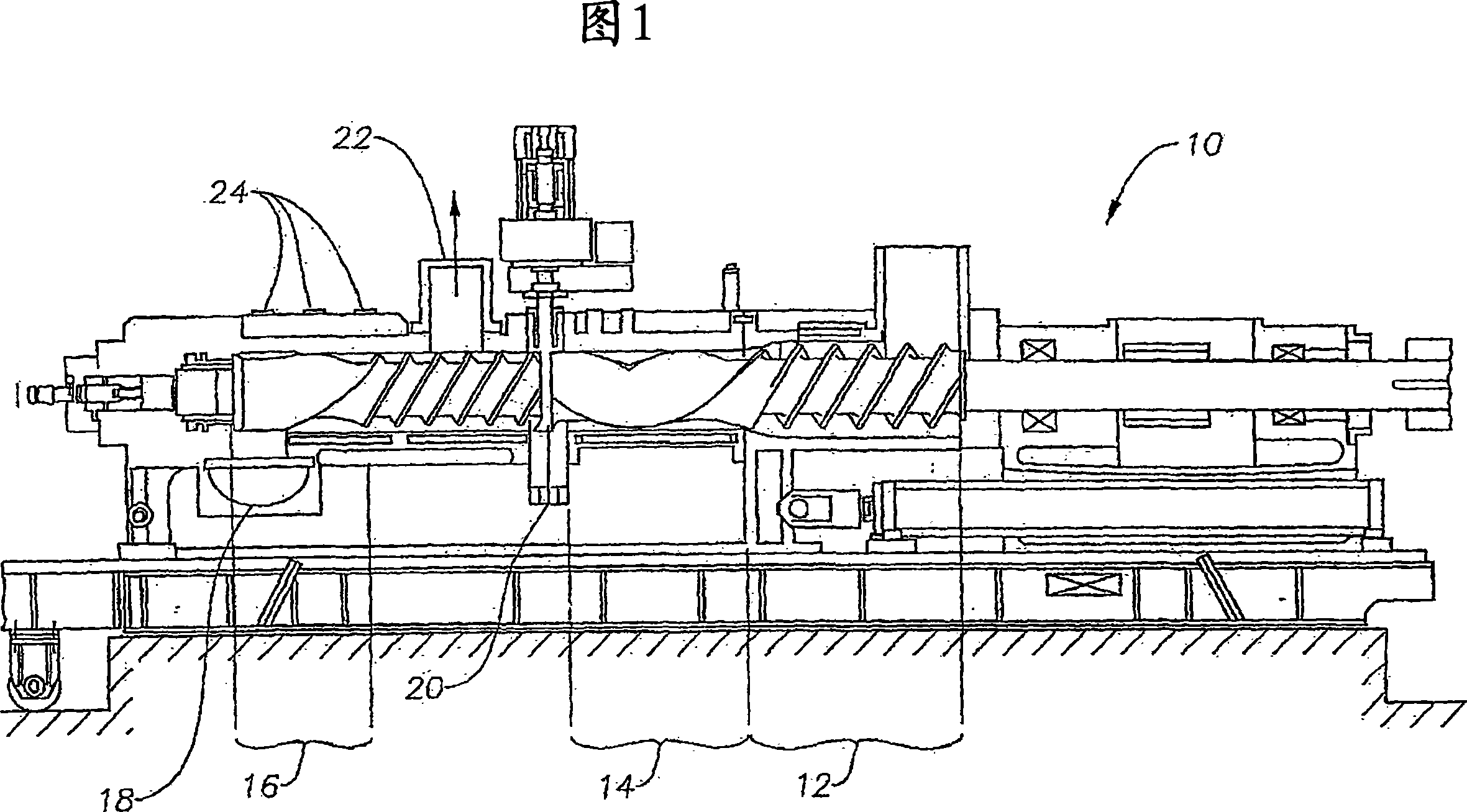

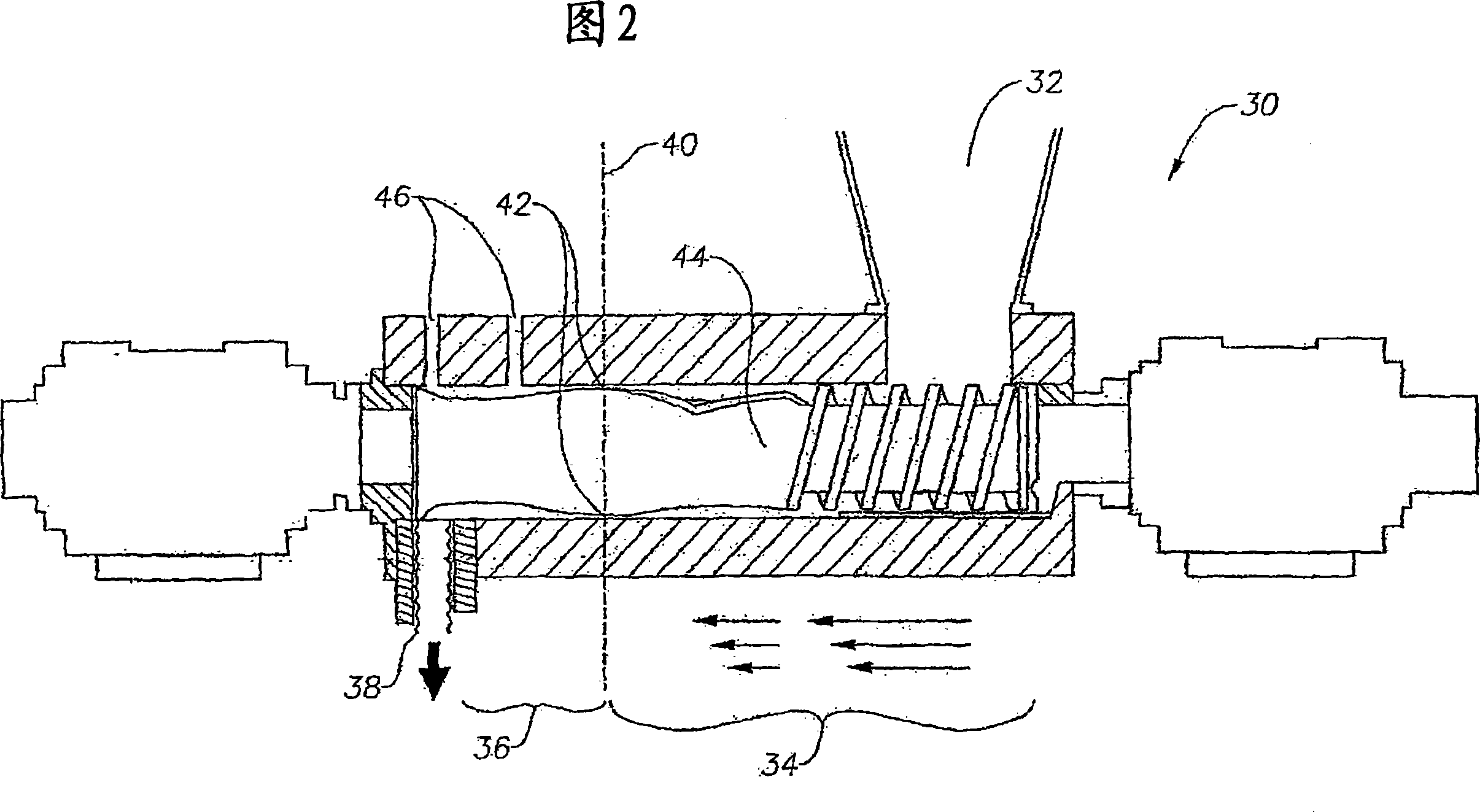

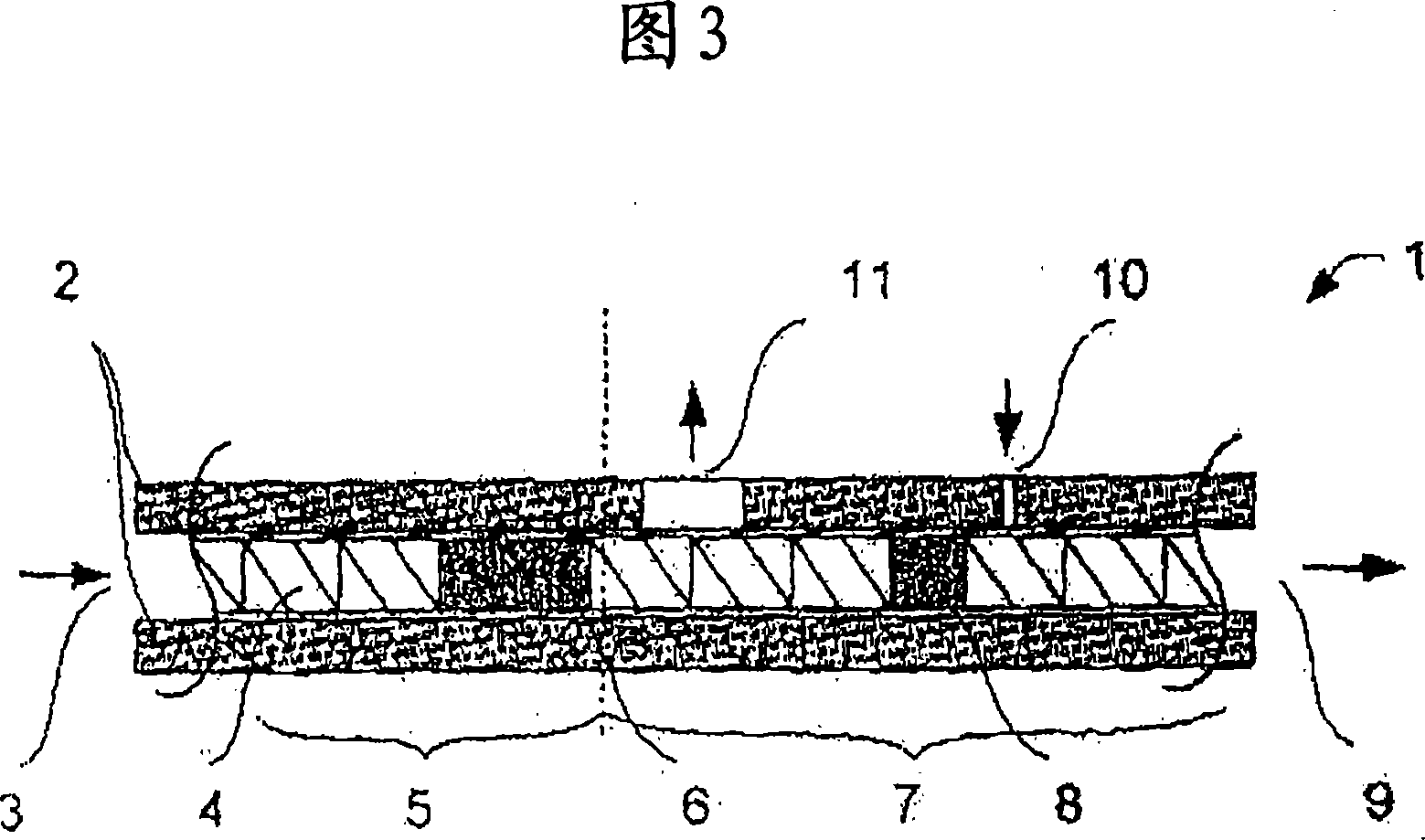

[0066] The device used to tailor the above polyethylene is a Coperion (Werner-Pfleiderer) ZSK-57 co-rotating twin-screw extruder. The schematic diagram is figure 3 and this figure shows the processing section (1) of the machine. The processing section comprises a barrel (2) and a screw (4) formed from modular elements. The resin, Exceed(R) 1018CA (available from Exxon Mobil Chemical Company, Houston, TX) in pellet or pellet form, had a nominal melt index of 1.0 g / 10 min, 0.918 g / cm 3 Resin of nominal density, compounded with 500ppm of Irganox(R)-1076 (both available from Ciba Specialty Chemicals, Basel, Switzerland) and 2000ppm of Weston 399 (available from GE Specialty Chemicals) and 800ppm of Dynamar(R) FX5920 (available available from 3M Company), the resin is fed to processing section (1 ) and conveyed from feed end (3) to discharge end (9). The processing section is divided into a melting zone (5) formed by kneading and counter-conveying screw elements and a melt convey...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com