Laser welding with filler wire method of aluminum alloy T-type shapes for boat

A technology of laser wire filling and welding method, which is applied in the direction of laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems of large deformation of T-shaped profiles, poor joint performance, poor applicability, etc., to avoid stability Reduction of properties, improvement of stability, and dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following are embodiments and effects of the present invention.

[0021] Experiment using CO 2 The laser parameters are: wavelength 10.6 μm, power 3500W.

[0022] The aluminum alloy material used in the experiment is: 5083 aluminum alloy with a thickness of 6mm.

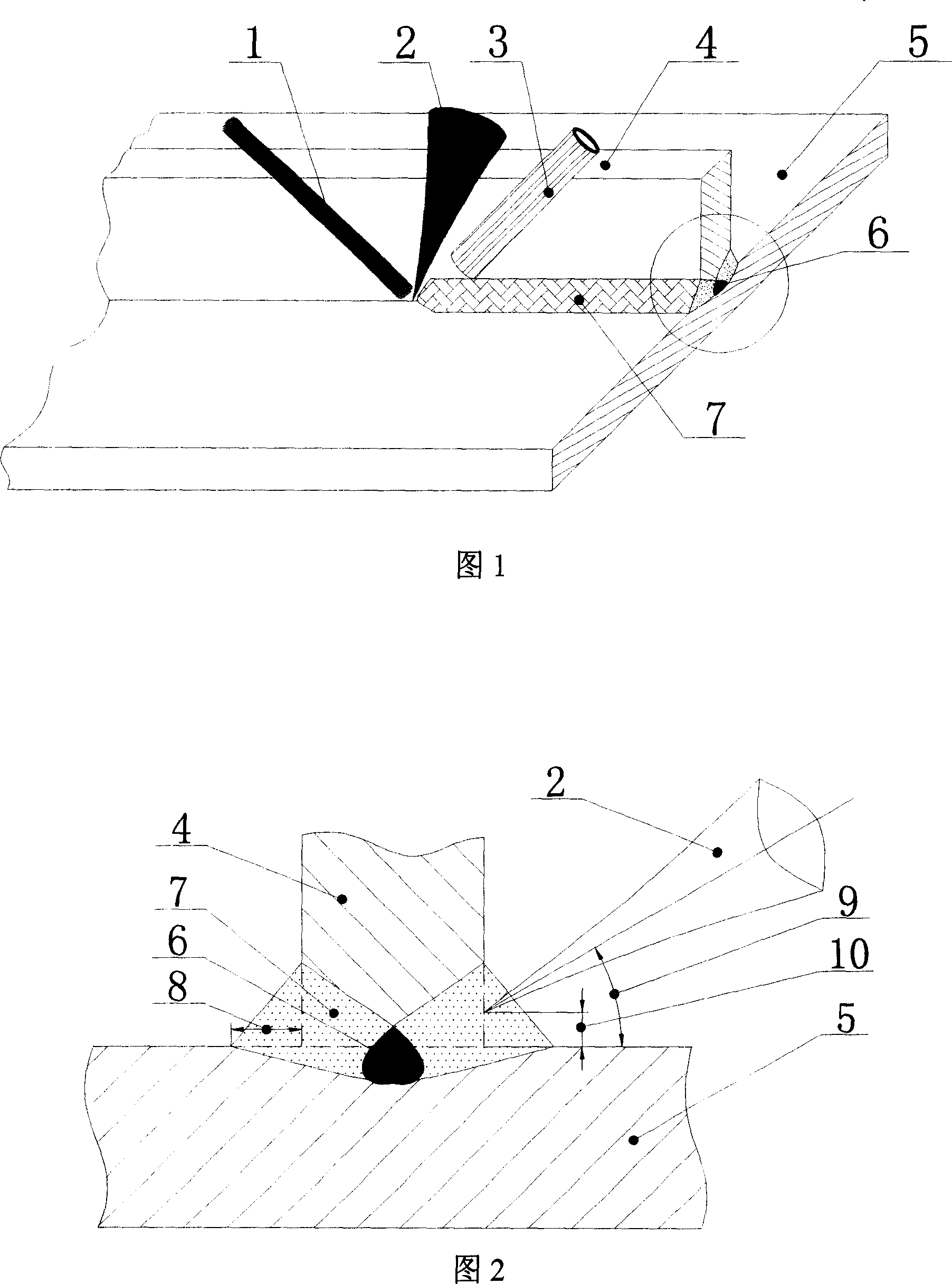

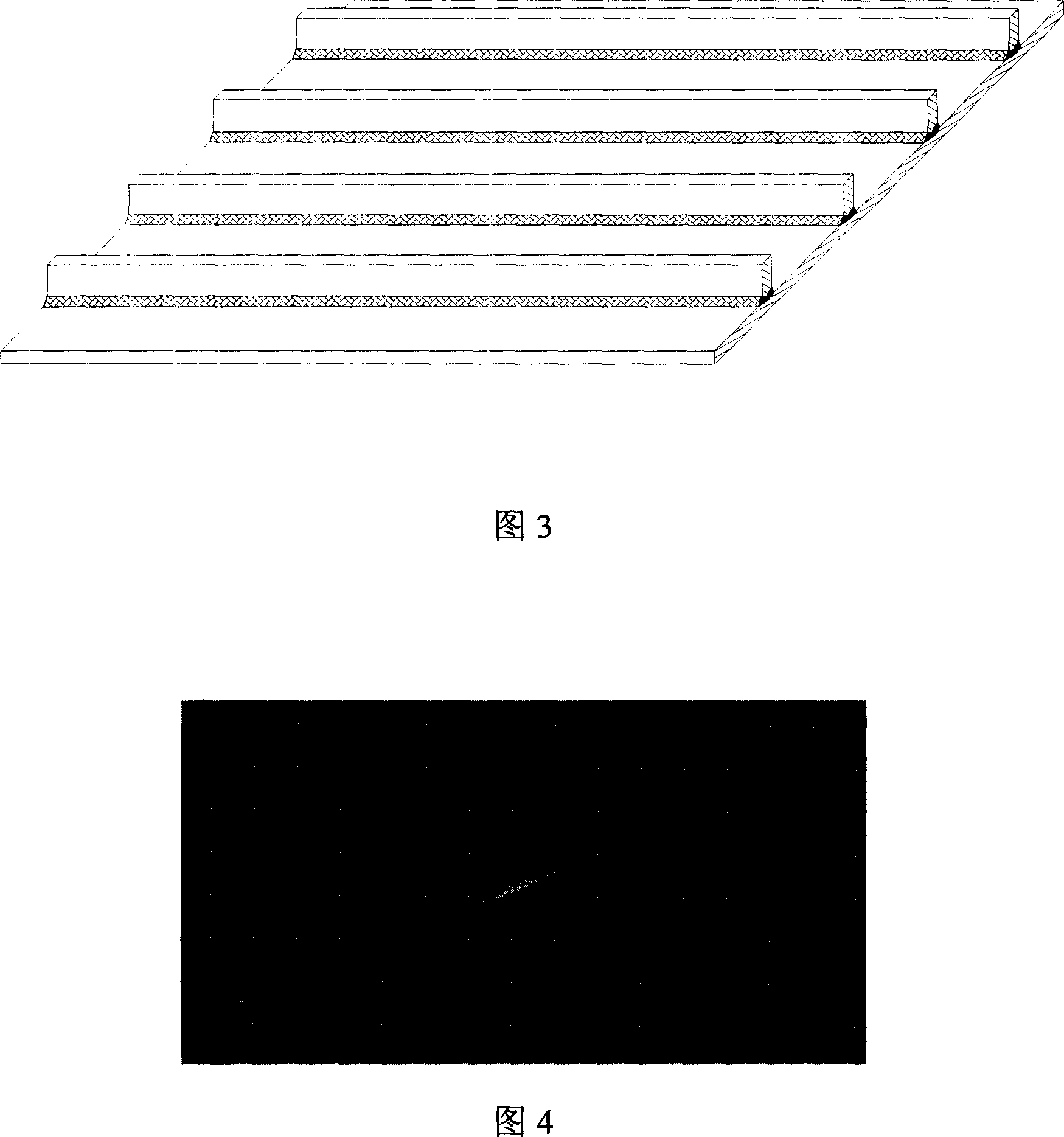

[0023] As shown in Figure 2 and Figure 3, before welding, the vertical plate 4 and the horizontal plate 5 are rigidly fixed and 90° to each other using a general fixture, the laser beam 2 is incident on the surface of the horizontal plate 5 at an angle of 30°, the welding wire 1, the nozzle 3 and laser beam 2 are in the same plane, welding wire 1 and nozzle 3 are arranged on both sides of laser beam 2, welding wire 1 and laser beam 2 form an angle of 45°, nozzle 3 and laser beam 2 form a mutual 45°, laser beam 2 acting on the vertical plate 4, the laser beam 2 and the vertical plate 4 have an offset 10 of 0.5mm relative to the upper surface of the horizontal plate 5, and the offset 10 is along the normal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com