Forming device of blank of cored ceramics and its forming method

一种陶瓷插芯、成型装置的技术,应用在模压成型领域,能够解决生产成本高、浪费原材料、生产效率低等问题,达到原料利用率高、生产成本降低、生产速度提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

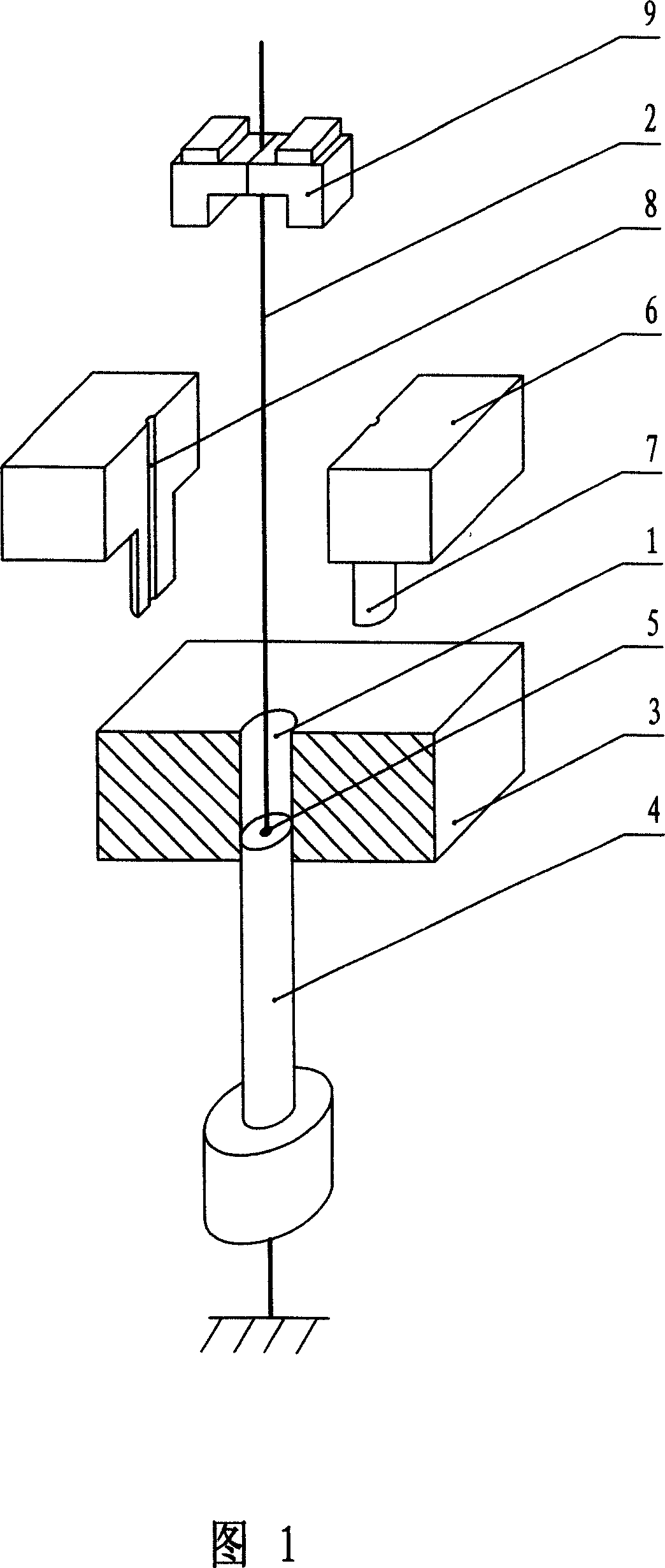

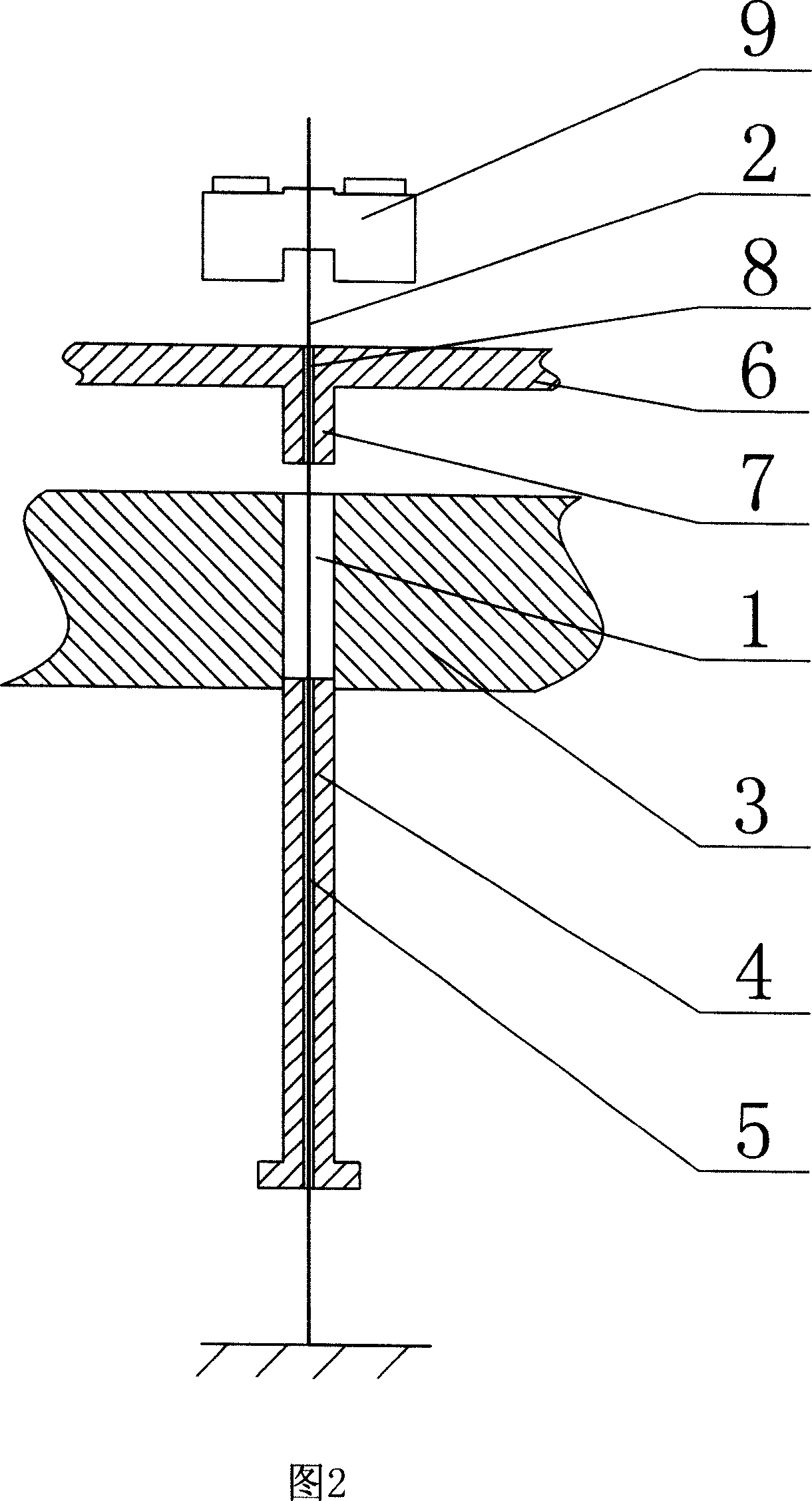

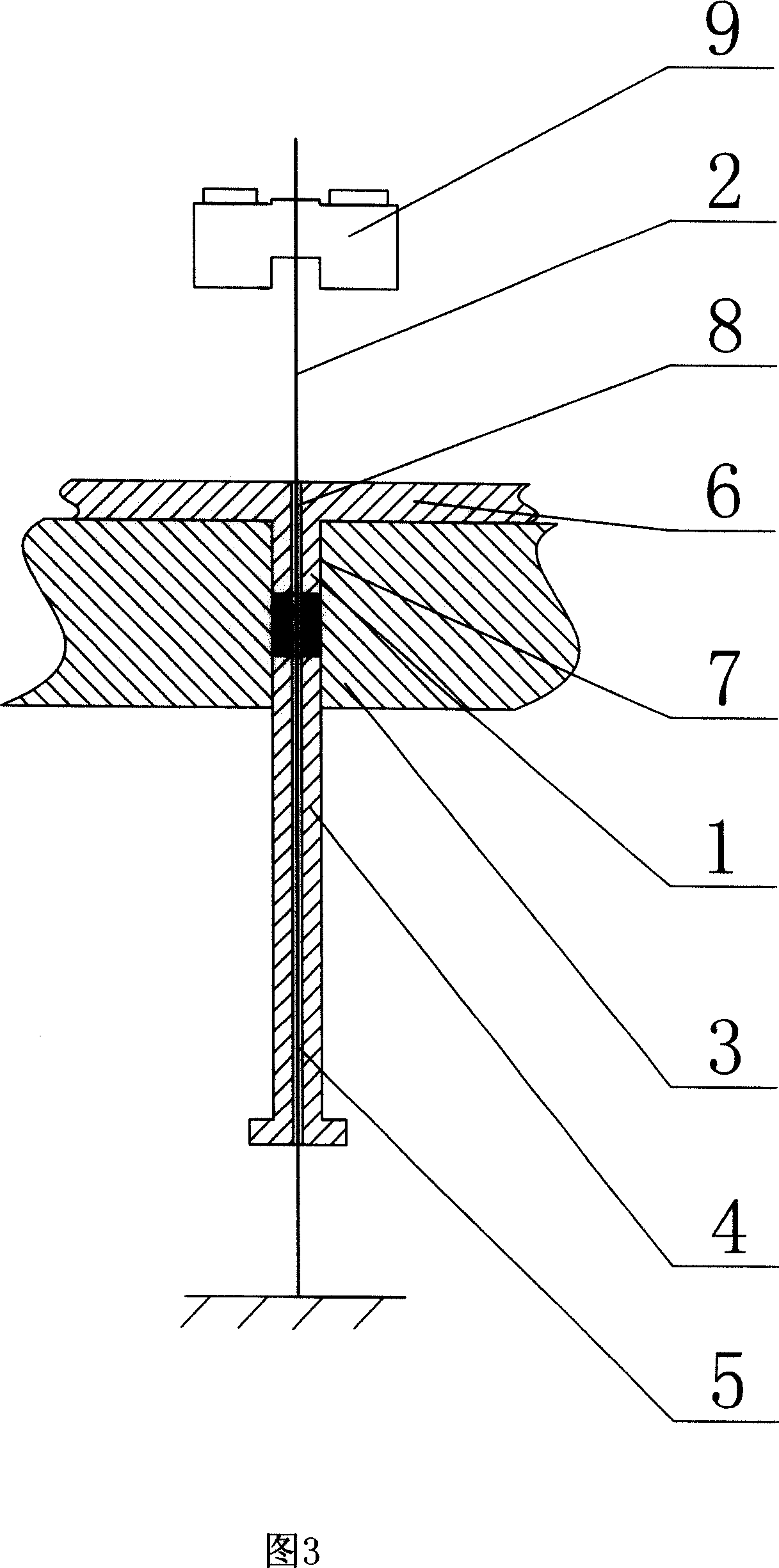

[0018] As shown in Figures 1 to 5, it is a molding device for ceramic ferrule blanks, including a mold cavity 1 for blank molding, a setting wire 2 arranged in the mold cavity 1, and the mold cavity 1 is formed by a molding template 3 The through hole on the top of the mold cavity 1 is provided with a thimble mold 4 in the lower opening of the through hole, and the axial middle part of the thimble mold 4 is provided with an axial hole 5 coaxial with the mold cavity 1, and the setting wire 2 passes through the shaft of the thimble mold 4. The end of the hole 5 is fixedly arranged below the thimble mold 4, a pair of punching half-molds 6 that can be opened and closed are arranged above the mold cavity 1, and the adjacent side ends of the two punching half-molds 6 are respectively provided with half-mold indenters 7, The joint surfaces of the two halves of the indenter 7 are respectively provided with an axial line groove 8 that penetrates up and down. When the two stamping halves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com