Strain reversible rehabilitation polymer and its preparing process

A polymer and polyurethane technology, applied in the field of reversible repair polymer preparation, can solve the problem of high repair temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

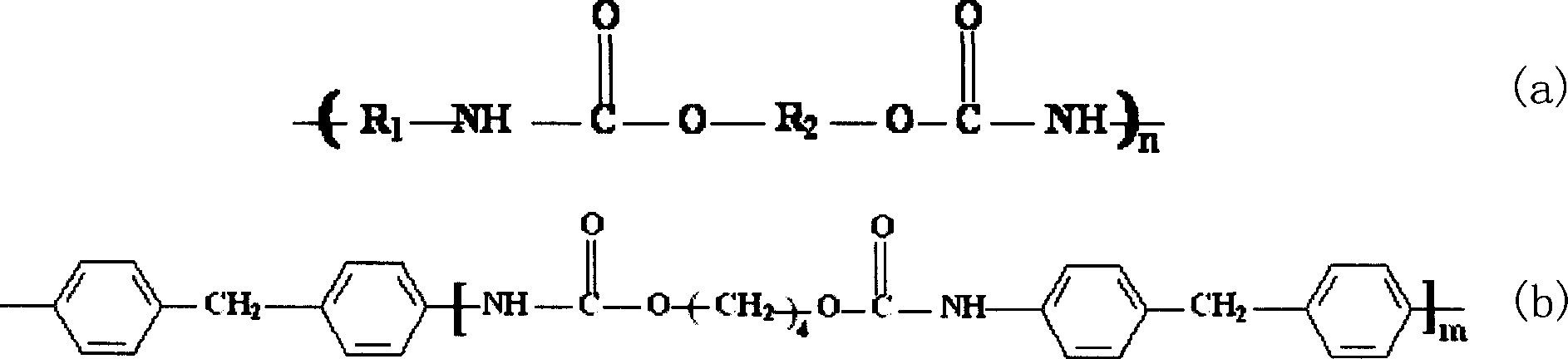

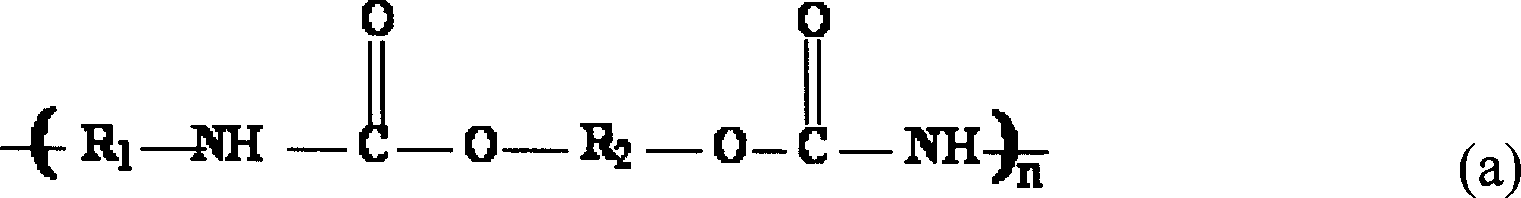

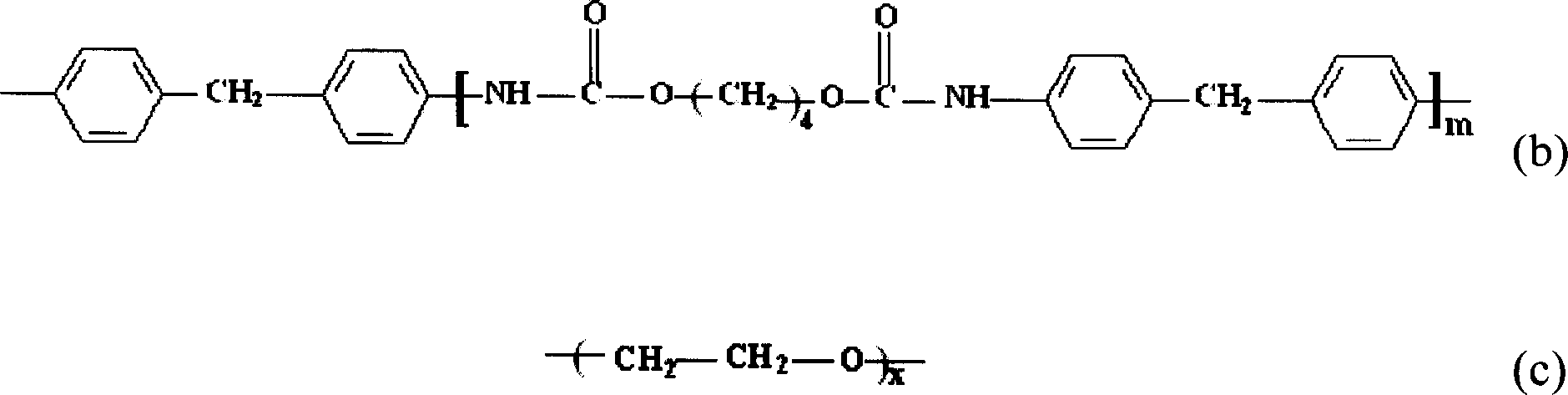

Method used

Image

Examples

Embodiment 1

[0016] Add 5.071g MDI and 1.676g BDO into a four-necked flask with nitrogen gas, put 50ml of DMF solvent to fully dissolve and stir evenly; react at 25°C, stop the reaction after about 30min; react at 65°C The MDI-BDO hard segment obtained is added dropwise to the DMF solution of 6.417g Polyethylene Glycol-6000 (number average molecular weight is 6000) containing 0.006g catalyst dibutyltin dilaurate, after the reaction is complete, use hot dehydrated alcohol precipitation, Wash, filter, and dry in a vacuum oven at 80° C. for 24 hours to obtain a block polyurethane product. The obtained product was placed in a Soxhlet extractor, and extracted with absolute ethanol for 24 hours to remove unreacted polyethylene glycol to obtain a polyurethane product with a dual continuous phase structure. The recovery efficiency of the impact toughness of this product under strain conditions is 75%.

Embodiment 2

[0018] Add 6.774g MDI and 2.06g BDO into a four-necked flask with nitrogen, put 60ml of DMF solvent to fully dissolve and stir evenly; react at 25°C, stop the reaction after about 25min; react at 60°C The MDI-BDO hard segment obtained is added dropwise to the DMF solution of 8.834g Polyethylene Glycol-1500 (the number average molecular weight is 1500) containing 0.007g catalyst dibutyltin dilaurate, after the reaction is complete, precipitate with hot dehydrated alcohol, Wash, filter, and dry in a vacuum oven at 80° C. for 24 hours to obtain a block polyurethane product. Put the obtained product into a Soxhlet extractor, extract with absolute ethanol for 24 hours, and obtain a polyurethane product after vacuum drying. The repair efficiency of impact toughness under strain conditions is 85%.

Embodiment 3

[0020] Add 7.340g MDI and 2.483g EG into a four-necked flask with nitrogen, put 50ml of DMF solvent to fully dissolve and stir evenly; react at 25°C, stop the reaction after about 30min; react at 65°C The hard segment of MDI-EG is added dropwise to the DMF solution of 11.625g polyethylene glycol-6000 (number average molecular weight is 6000) containing 0.010g catalyst dibutyltin dilaurate, after the reaction is complete, precipitate and wash with hot absolute ethanol , filtered, and dried in a vacuum oven at 80° C. for 24 hours to obtain a block polyurethane product. Put the obtained product into a Soxhlet extractor, extract with absolute ethanol for 24 hours, and obtain a polyurethane product after vacuum drying. The impact toughness repair efficiency under strain conditions was 78%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com