Axial center aeration and jet-booster type stirring fermenter

A stirring fermentation, booster technology, applied in bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical instruments, etc., can solve the problem of low oxygen utilization rate and save compressed air power source , the effect of increasing product concentration and increasing dissolved oxygen rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

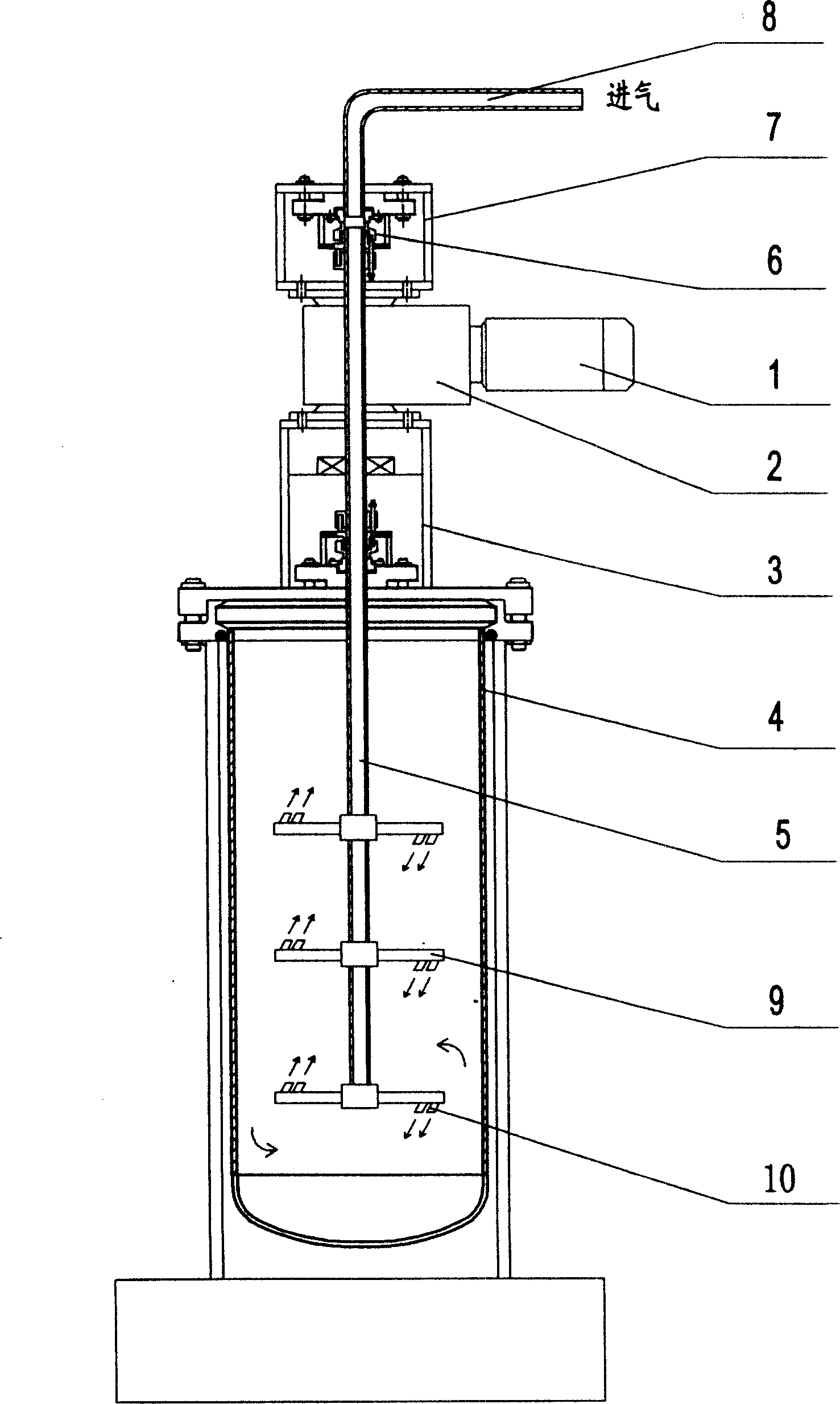

[0010] The fermenter adopts a general-purpose mechanical stirring fermenter tank structure, and only the stirring ventilation system is described.

[0011] This equipment adopts a fixed product in the form of motor 1 side-mounted and reducer 2 directly connected. The design and selection of the reducer is in the form of a straight-through output shaft at the upper and lower ends. The speed reducer 2 is installed on the upper end of the fermenter tank body 4 through the bracket 3 .

[0012] The stirring shaft 5 is made of thick-walled seamless pipe, which is precisely processed (to ensure concentricity). Generally, it should be made into two parts, that is, the upper half shaft and the lower half shaft (a particularly small reactor can be made into one shaft). The fixed support method of the shaft is basically the same as that of ordinary reactors. The difference is that the upper extension of the shaft is provided with an inverted mechanical seal 6 for the introduction of co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com